Loading...

Loading...

Do you have a question about the Kärcher 1.575-615.0 and is the answer not in the manual?

| Brand | Kärcher |

|---|---|

| Model | 1.575-615.0 |

| Category | Pressure Washer |

| Language | English |

Covers warnings on ear protection, eye wear, flammables, explosions, fire, and safe operating areas.

Details risks like burns, injection, freezing, asphyxiation, falls, and high-pressure spray hazards.

Outlines guidelines for machine operation, hose safety, and approved fuel types.

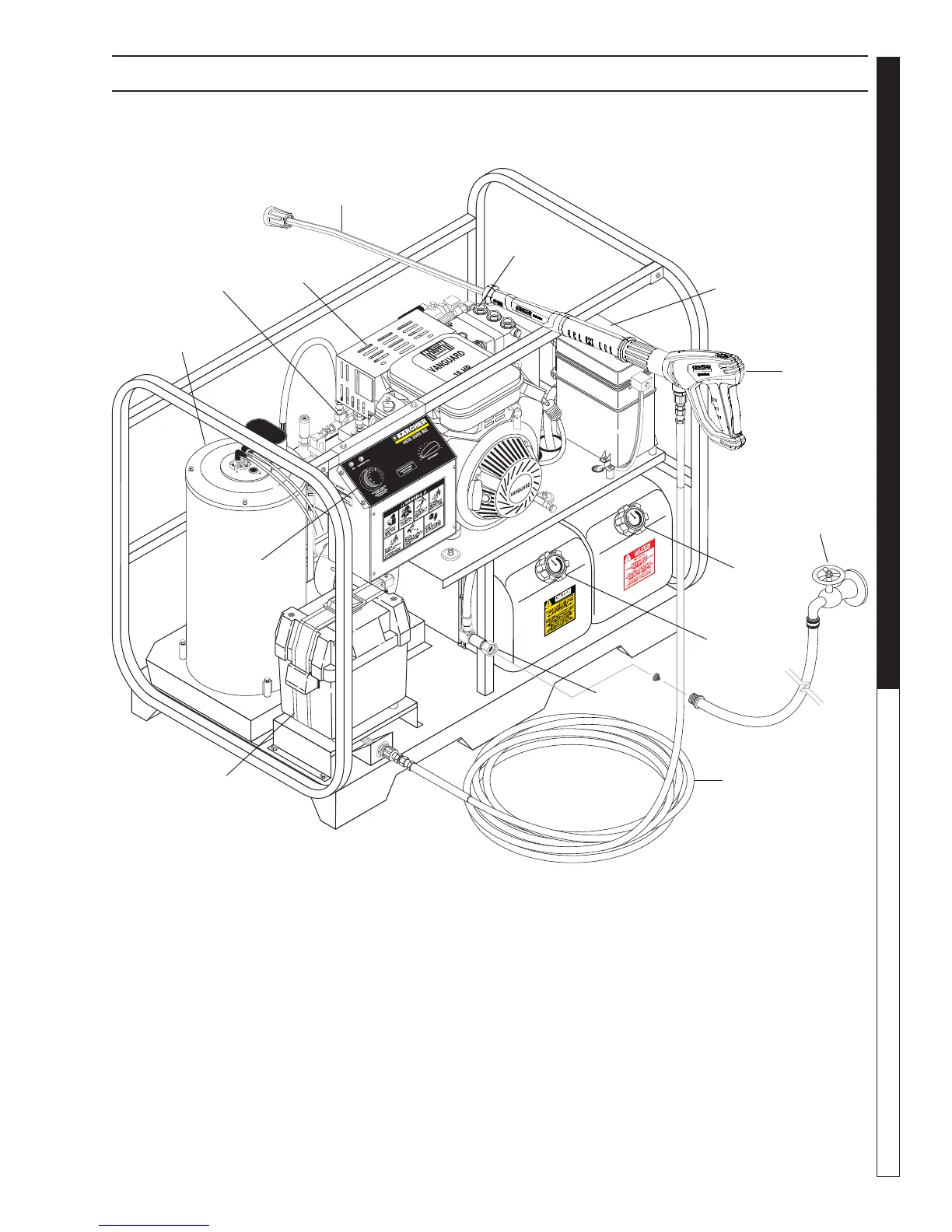

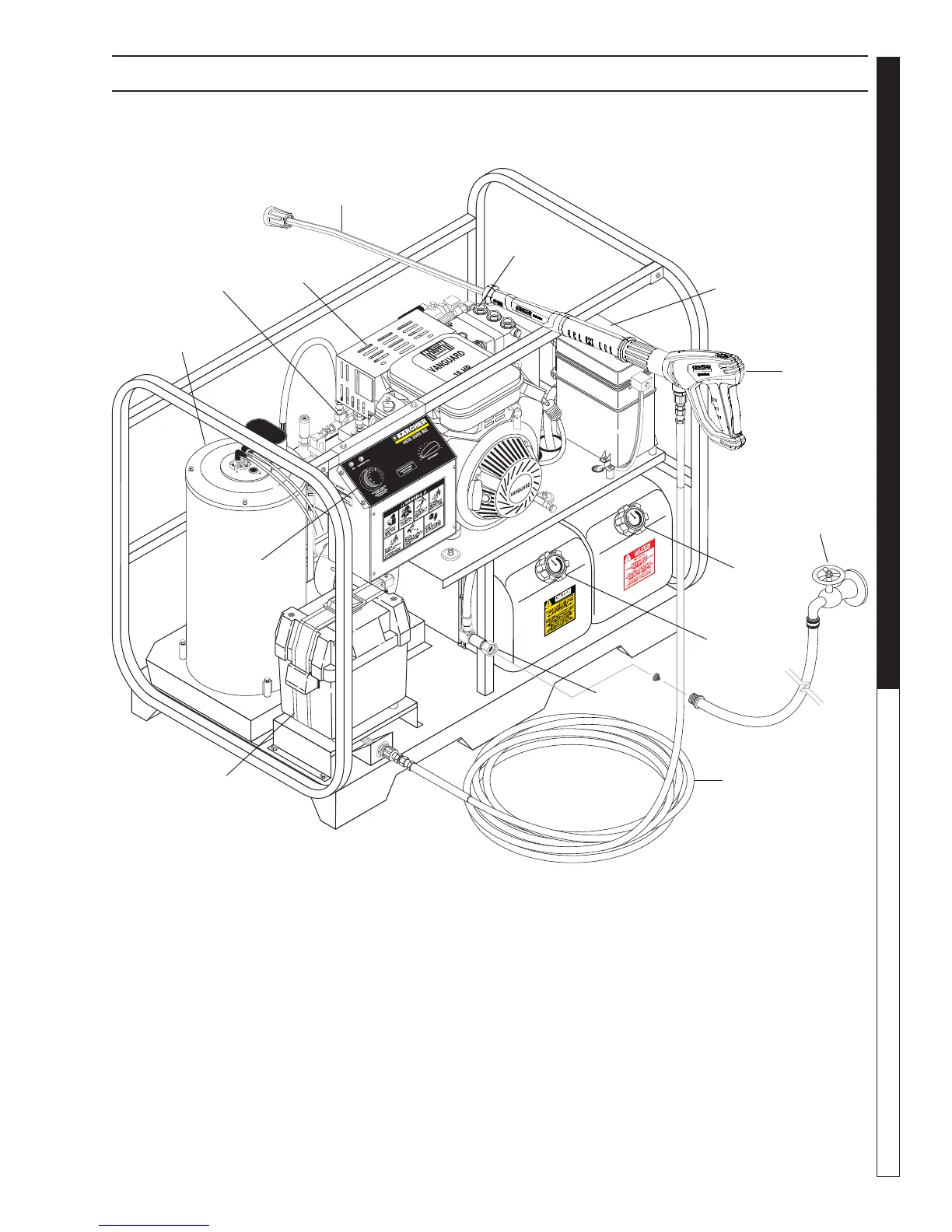

Details on checking oil, fuel, priming, and starting using the pull-start method.

Steps for starting the engine using electric start and initial burner operation.

Instructions for turning on the burner and setting the thermostat dial.

Lists common causes and solutions for insufficient operating pressure.

Details common causes and fixes when the burner fails to light.

Covers continued burner ignition problems and causes of fluctuating pressure.

Addresses machine smoking, causes, and troubleshooting air adjustment problems.

Solutions for low water temperature and water temperature that is too hot.

Troubleshooting for noisy pumps, water in oil, and water dripping from the pump.

Step-by-step guide on adjusting the VRT3 unloader for desired pressure settings.