Section 2 Operation

2.1 Prestart Checklist

To ensure continued satisfactory operation, perform the

following checks or inspections before or at each

startup, as designated, and at the intervals specified in

the service schedule. In addition, some checks require

verification after the unit starts.

Air Cleaner. Check for a clean and installed air cleaner

element to prevent unfiltered air from entering the

engine.

Air Inlets. Check for clean and unobstructed air inlets.

Battery. Check for tight battery connections. Consult

the battery manufacturer's instructions regarding

battery care and maintenance.

Exhaust System. Check for exhaust leaks and

blockages. Check the muffler and piping condition and

check for tight exhaust system connections.

Inspect the exhaust system components (exhaust

manifold, exhaust line, flexible exhaust, clamps, muffler,

and outlet pipe) for cracks, leaks, and corrosion.

• Check for corroded or broken metal parts and replace

them as needed.

• Check for loose, corroded, or missing clamps and

hangers. Tighten or replace the exhaust clamps

and/or hangers as needed.

• Check that the exhaust outlet is unobstructed.

• Visually inspect for exhaust leaks (blowby). Check

for carbon or soot residue on exhaust components.

Carbon and soot residue indicates an exhaust leak.

Seal leaks as needed.

Oil Level. Maintain the oil level at or near, not over, the

full mark on the dipstick.

Operating Area. Check for obstructions that could

block the flow of cooling air. Keep the air intake area

clean. Do not leave rags, tools, or debris on or near the

generator set.

x:op:001:002

2.2 Exercising the Generator Set

Operate the generator set under load once each week

for one hour. If the generator set does not have a

programmed exercise mode or an automatic transfer

switch (ATS) with an exercise option, exercise the unit in

the presence of an operator.

During the exercise period apply a minimum of 35% load

based on the nameplate standby rating.

The operator should perform all of the prestart checks

before starting the exercise procedure. Start the

generator set according to the starting procedure in the

controller section of this manual. While the generator

set is operating, listen for a smooth-running engine and

visually inspect the generator set for fluid or exhaust

leaks. Check the air inlets and outlets and remove any

items restricting the air flow.

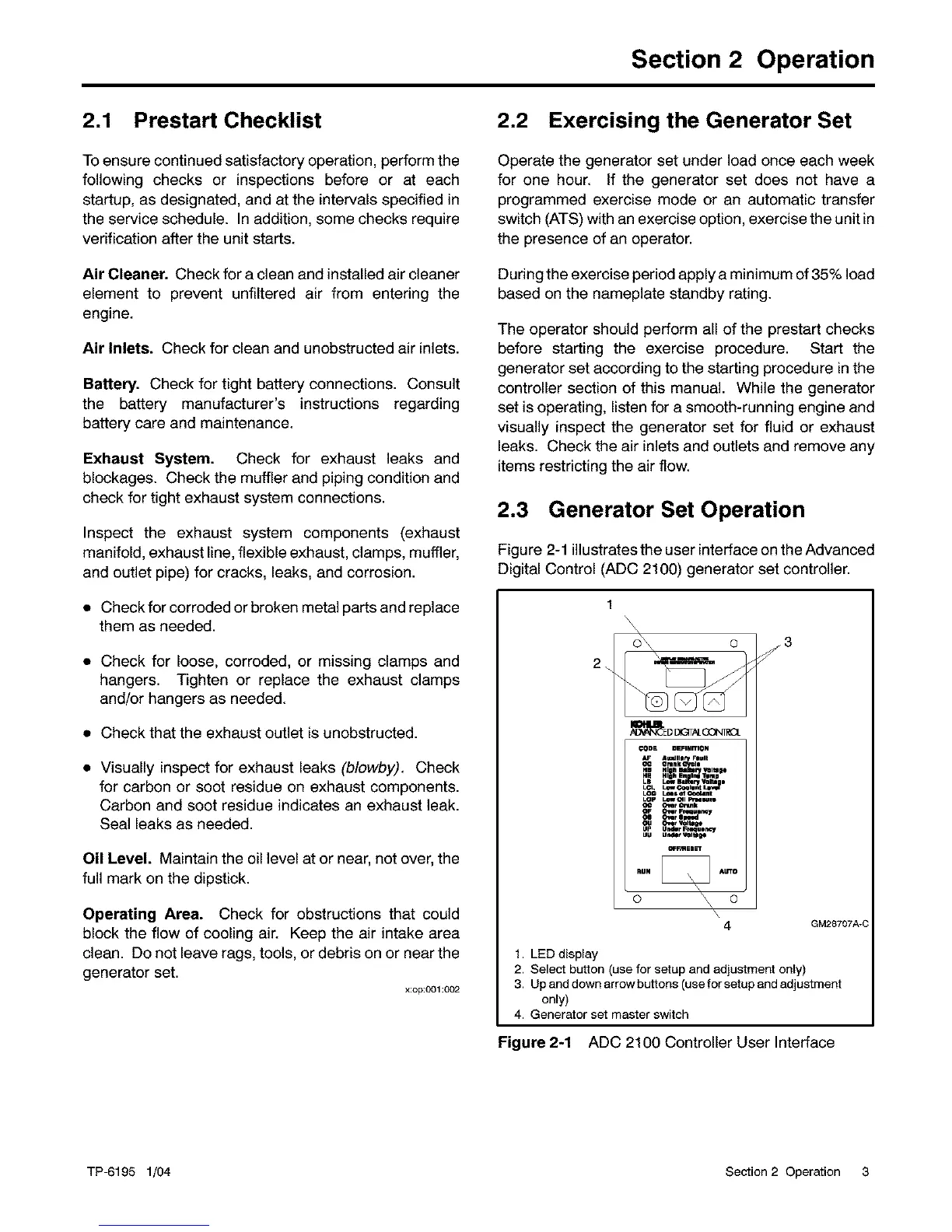

2.3 Generator Set Operation

Figure 2-1 illustrates the user interface on the Advanced

Digital Control (ADC 2100) generator set controller.

2_

\

\

_'ED D_T_._

COnE nEFImTION

_,_ A_JII i _ull

Cmn_l*

Hn Hlgll _ "a11_Ip

He Hlllh_en I_ lllmp

L_L LOW 4_1411mn4 Lllt_

LOC LU= of CNMn=

LOp LOW G41Ll_'lOFJr4p

C4_ _r Ct, lnk

= _; ."',..?='

uU_ Oser voltep

Under _u*_'i,

_FmSllmr

RUN _ AU'TO

o o

x

4

J

GM28707A-C

1. LED display

2. Select button (use for setup and adjustment only)

3, Up and down arrow buttons (use for setup and adjustment

only)

4, Generator set master switch

Figure 2-1 ADC 2100 Controller User Interface

TP-6195 1/04 Section 2 Operation 3

Loading...

Loading...