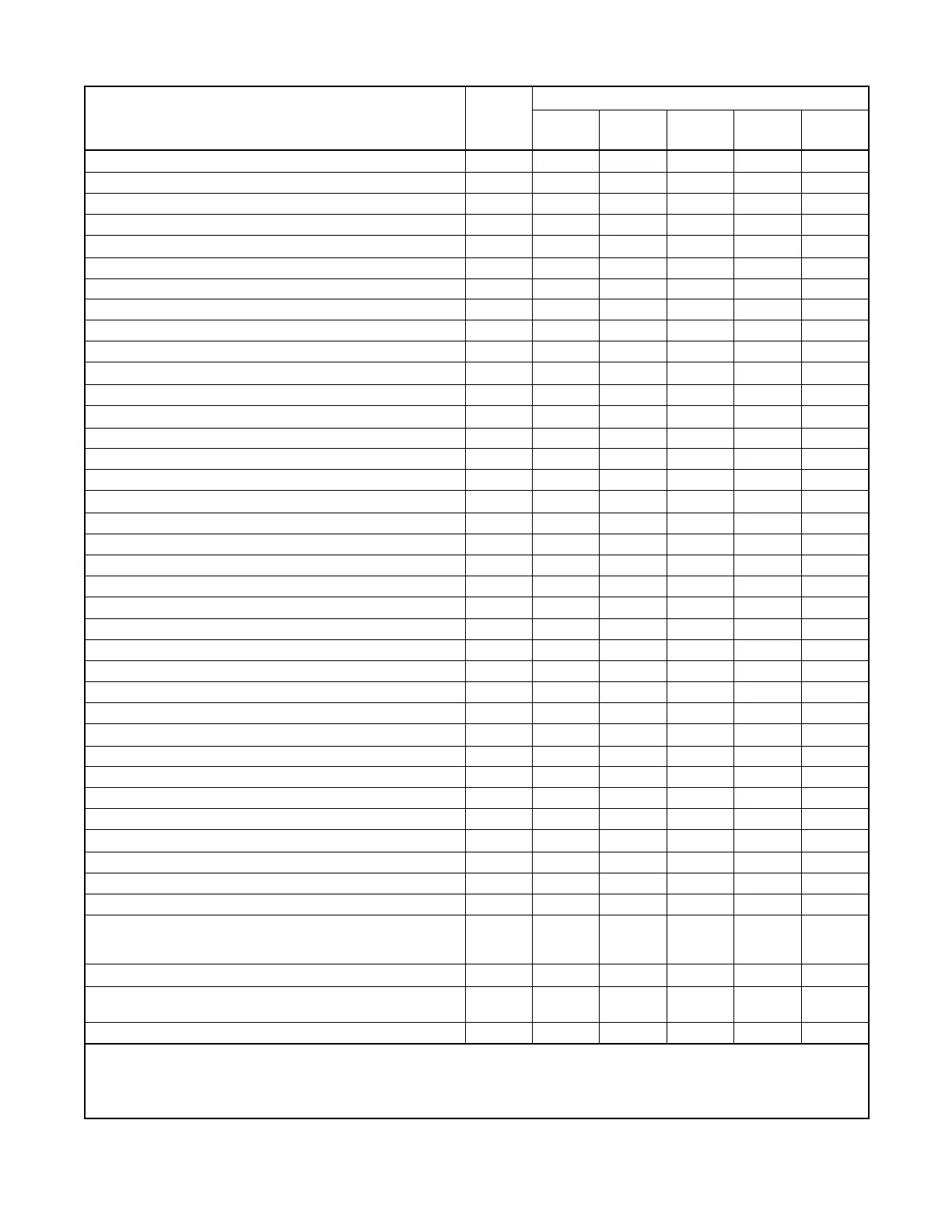

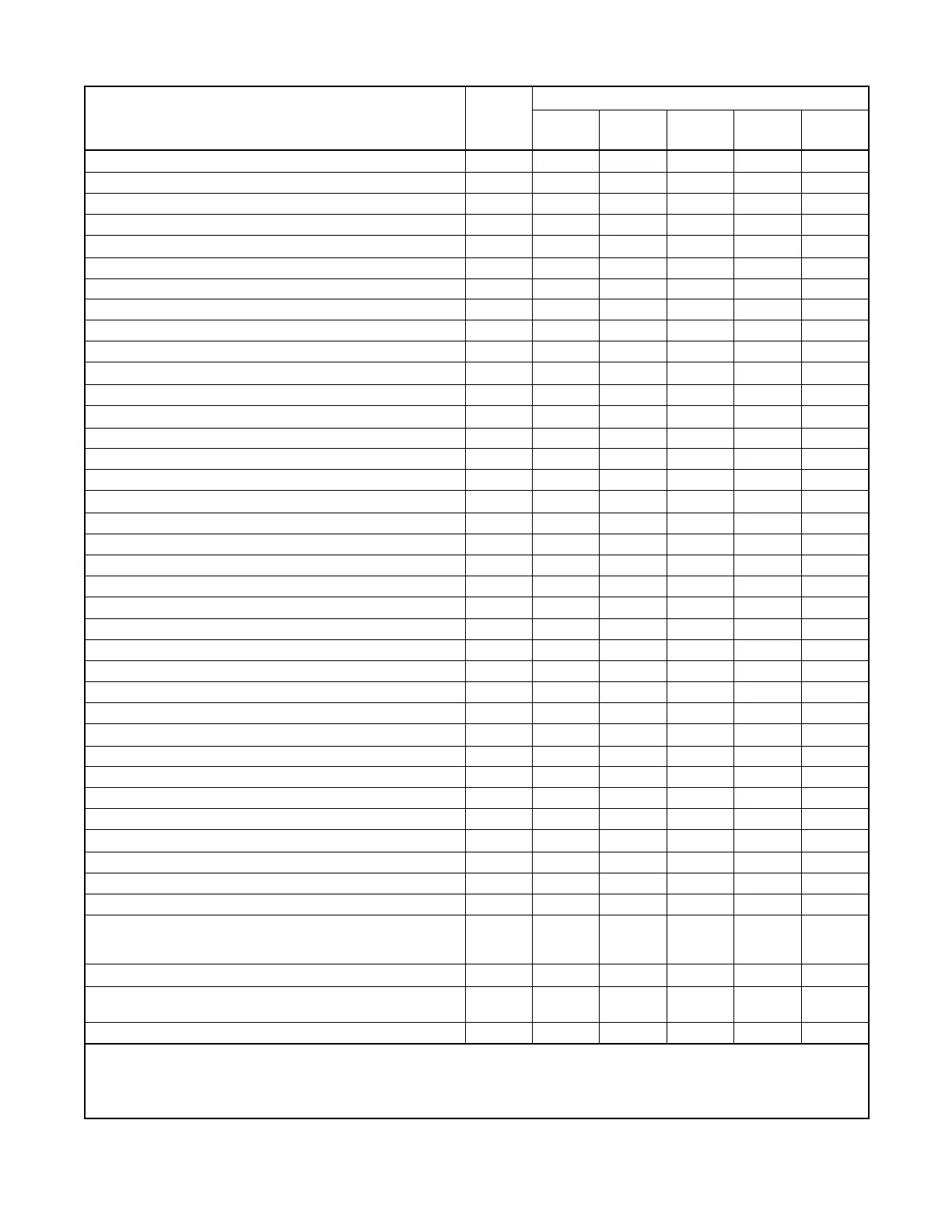

TP-6517 4/0934 Section 4 Scheduled Maintenance, 17/18 kW Models

4.2 Service Schedule, 17/18 kW Models

System Component or Procedure

See

Section

Procedure

Visually

Inspect

Check Change Clean Test

Fuel

Flexible lines and connections Q R

Main tank supply level W

Fuel piping Y

Lubrication

4.3

Oil level 8orE

Change oil Y or 150

Replace filter Y or 150

Crankcase breather hose Y or 500

Oil cooler Y Y or 100

Cooling

4.6

Air ducts, louvers Y Y

Exhaust System

4.7

Leakage W W

Insulation, fire hazards Y

Obstructions or combustible materials near exhaust outlet W

DC Electrical System

4.8

Battery charger operation, charge rate M

Remove corrosion, clean and dry battery and rack Y Y

Clean and tighten battery terminals and inspect boots Y Y

Battery electrolyte level and specific gravity * Y

AC Electrical System

Tighten control and power wiring connections Y

Remote control system, if equipped M

Visible wear or damage Q

Wire abrasions where subject to motion 6 months 6 months

Wire-cable insulation condition 3Y or 500

Engine and Mounting

Visible wear or damage W

Air cleaner service [

4.5 150 300

Spark plugs 4.4 150 300

Replace stepper motor coupling and bushing S/M 500 (D)

Generator

Visible wear or damage 2.1 Q

Exercise generator set 2.5 W

Brushes and collector ring S/M Y(D) Y(D)

Measure and record resistance readings of windings with

insulation tester (Meggerr, with SCR assembly or rectifier and

load leads disconnected)

S/M 3Y (D)

General Condition of Equipment

Evidence of vibration, leakage, deterioration, unusual or

excessive noise or temperature

W W W

Interior of sound enclosure Q Q

* Not necessary for maintenance-free batteries.

[ Service more frequently under extremely dusty/dirty conditions.

Meggerr is a registered trademark of Biddle Instruments.

EEachuse

W Weekly

M Monthly

Q Quarterly

Y Yearly

Number = hours of operation

D Authorized distributor/dealer only

R Replace as necessary

S/M Service Manual

Loading...

Loading...