TP-6109 6/03 17Section 2 Operation

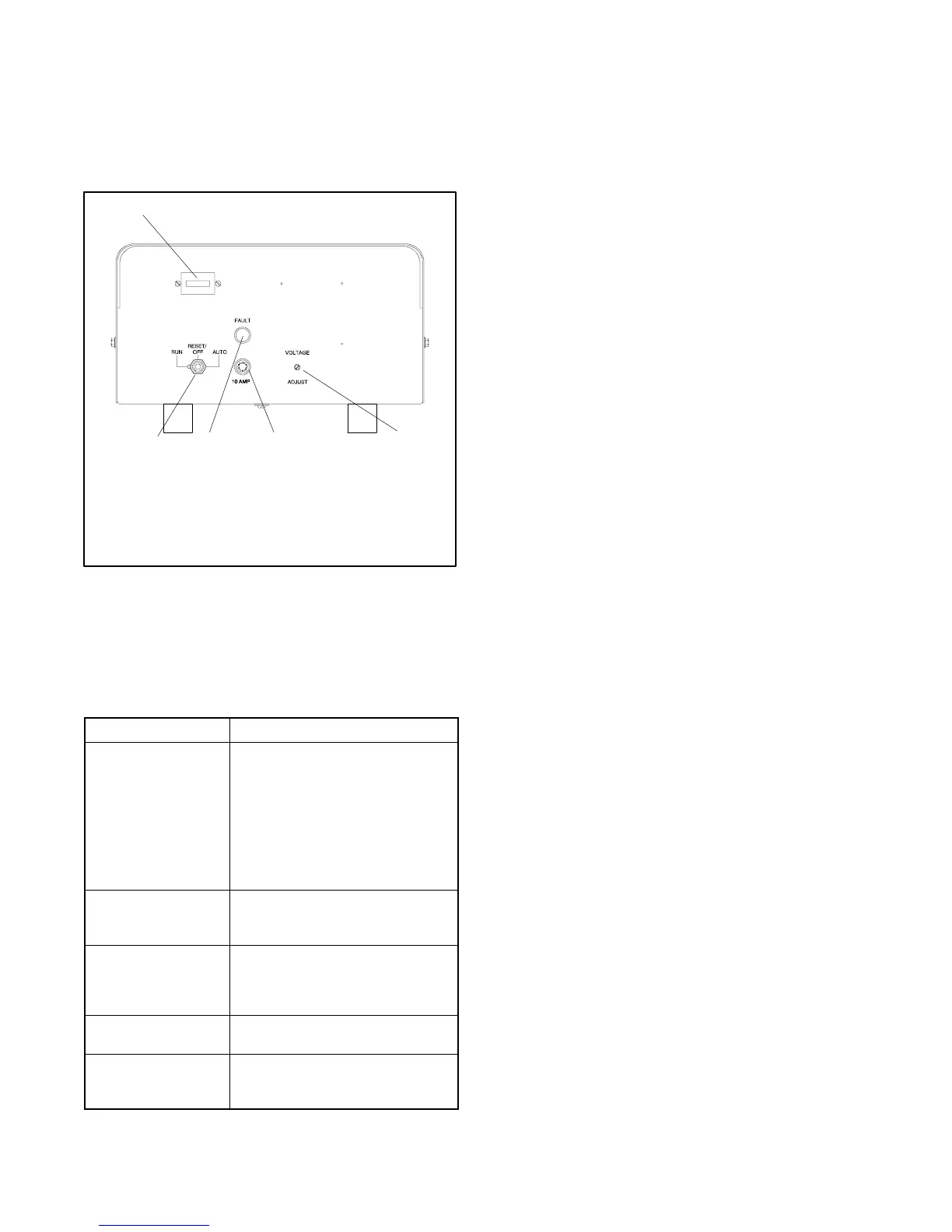

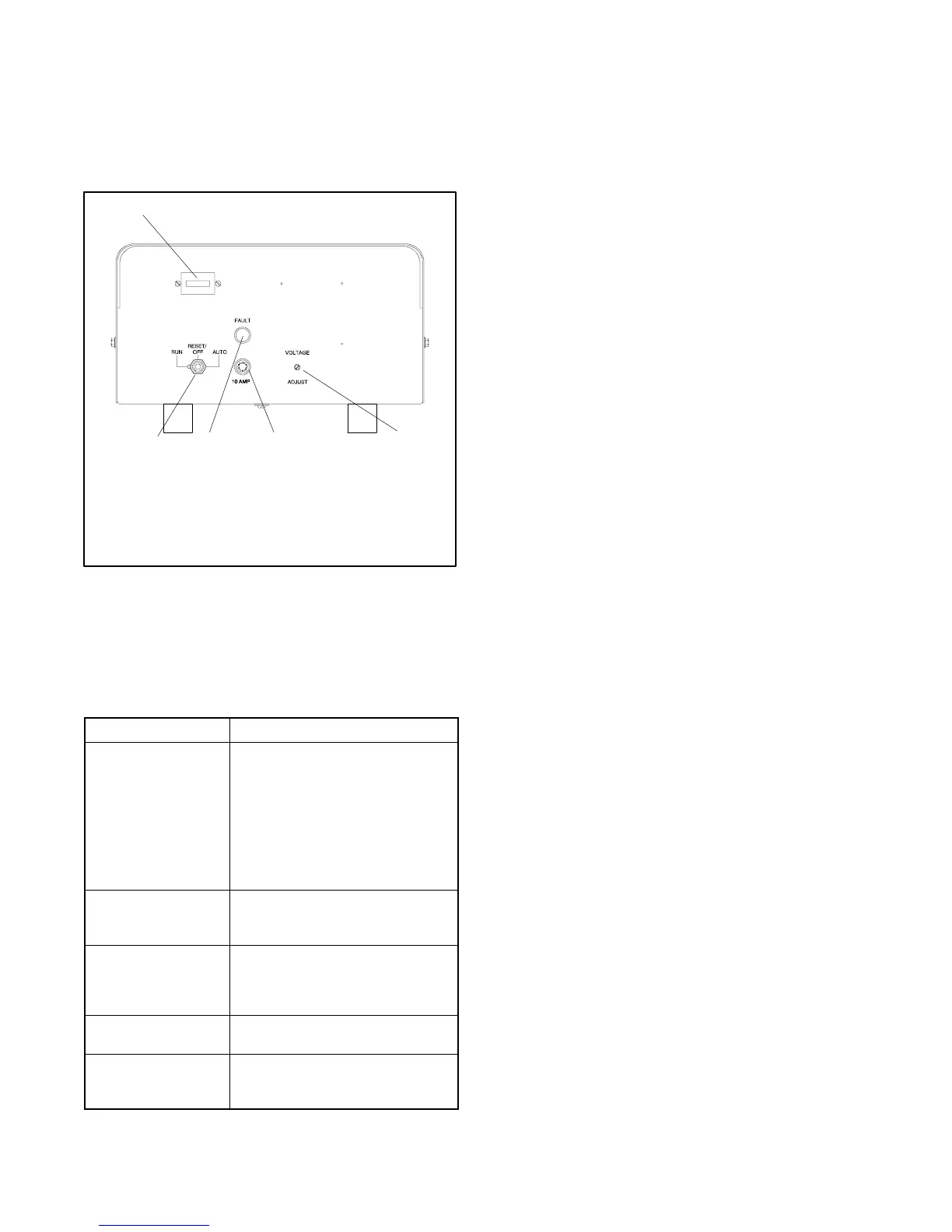

2.8 Standard Decision-Makert 1

Controller Operation

For identification of the standard basic controller’s

indicators and controls and their functions, refer to

Figure 2-5.

A-227600

1

345

1. Hourmeter

2. Voltage adjustment

3. 10-amp controller fuse

4. Fault lamp

5. Generator set master switch

2

Figure 2-5 Decision-Maker t 1 Controller

x:op:004:001

2.8.1 Controls and Indicators

The following table describes the controls and indicators

located on the controller.

Name Description

Fault lamp Lamp illuminates during engine

shutdown if the engine shuts down

because of one of the following

faults: high engine temperature,

low water level, low oil pressure,

overcrank, or overspeed. See

Section 2.8.4, Fault Shutdowns,

for additional shutdown

information.

Generator set master

switch

Switch functions as the controller

reset and generator operation

switch.

Hourmeter Hourmeter records the generator

set total operating hours for

reference in maintenance

scheduling.

Voltage adjust

potentiometer

Potentiometer fine-tunes (±5%)

generator output voltage.

10-amp controller

fuse

Fuse protects the controller

circuitry from short circuits and

overloads.

x:op:004:002

2.8.2 Starting the Generator Set

The following procedures describe starting the

generator set.

Local Starting. Move the generator set master switch

to the RUN position to immediately start the generator

set.

Automatic (Auto) Starting. Move the generator set

master switch to the AUTO position to allow startup by

the automatic transfer switch or the remote start/stop

switch (connected to controller terminals TB1-3 and

TB1-4).

Note: The controller provides up to 30 seconds of

continuous cranking before the overcrank

shutdown occurs.

2.8.3 Stopping the Generator Set

The following procedure describe how to stop the

generator set.

Normal Stopping

1. Cooldown. Run the generator set at no load for

5 minutes to ensure adequate engine cooldown.

2. Stopping. Move the generator set master switch

to the OFF/RESET position. The engine stops.

x:op:004:004

Loading...

Loading...