4324 690 07 Rev. H KohlerEngines.com

Electrical System

Test Ignition Modules and Connections (Smart-

Spark

™

only)

NOTE: Resistance values apply only to modules that

have been on a running engine. New service

modules may have higher resistance until they

have been run.

1. Remove blower housing from engine. Inspect wiring

for any damage, cuts, bad crimps, loose terminals,

or broken wires.

2. Disconnect leads from ignition module(s) and clean

all of terminals (male and female) with aerosol

electrical contact cleaner to remove any old

dielectric compound, dark residue, dirt, or

contamination. Disconnect spark plug leads from

spark plugs.

3. Remove one mounting screw from each ignition

module. If mounting screws are black, remove them

both and discard. Look in mounting hole with a

ashlight and use a small round wire brush to

remove any loose rust from laminations inside

mounting hole.

4. Use a digital ohmmeter to check resistance values

and compare them to ignition module resistance

table. When testing resistance to laminations, touch

probe to laminations inside screw hole, as some

laminations have a rust preventative coating on

surface which could alter resistance reading.

Condition Possible Cause Conclusion

All resistance values are within

ranges specied in table.

Ignition Module Gap Check and adjust ignition module

gap.

At least 1 resistance value is not

within ranges specied in table.

Ignition Module Ignition module is faulty and should

be replaced.

2

1

4

2

1

3

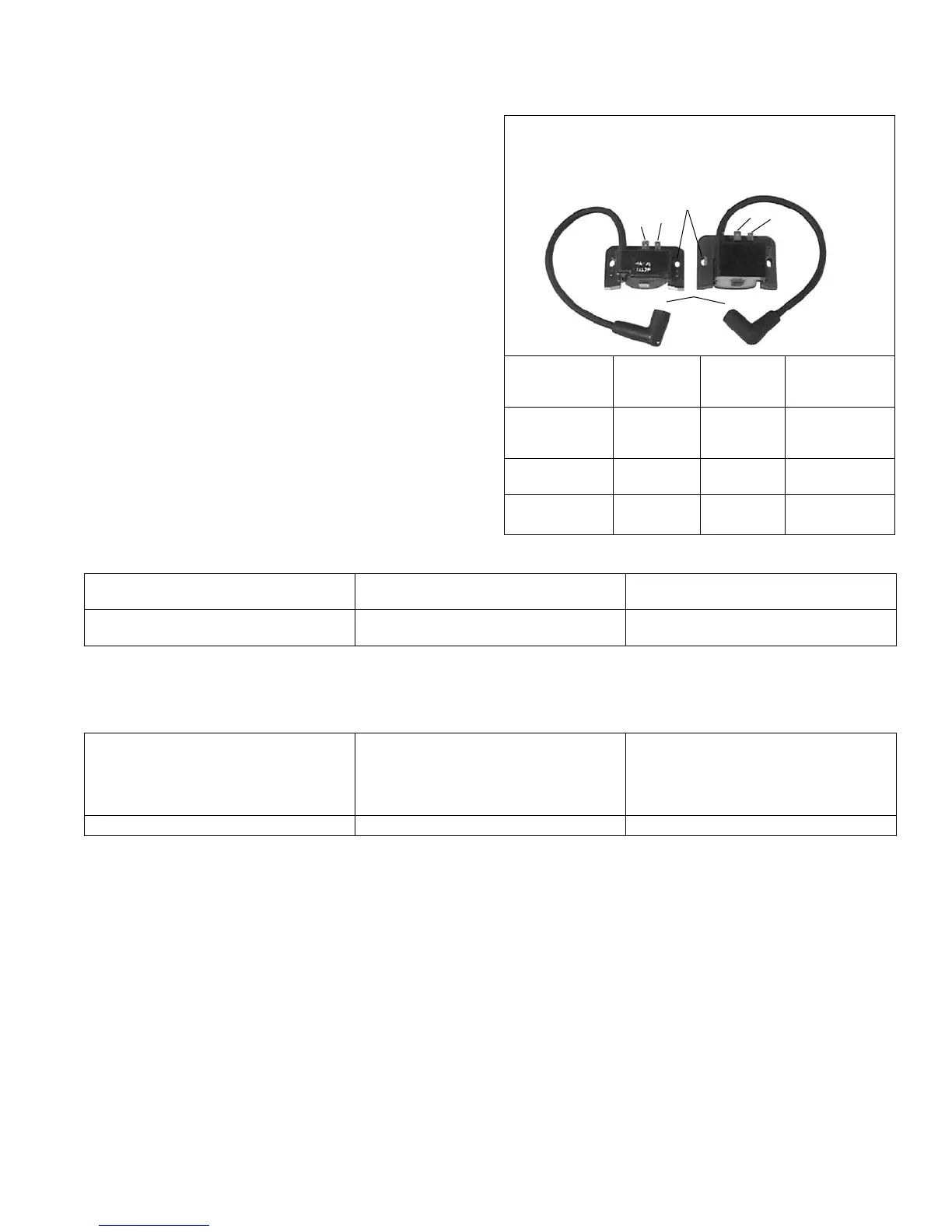

24 584 03

or

24 584 11

(1 11/16 in. High)

24 584 15-S

or

24 584 36-S

(2 1/16 in. High)

Test

(Use Digital

Ohmmeter)

From No.

1 to 4

From No.

2 to 4

From No.

3 to 4

24 584 03

24 584 11

(1 11/16 in. H)

945 to

1175 ohms

149 to

166 ohms

3750 to

7000 ohms

24 584 15-S

(2 1/16 in. H)

890 to

1175 ohms

119 to

136 ohms

5600 to

9000 ohms

24 584 36-S

(2 1/16 in. H)

590 to

616 ohms

183 to

208 ohms

8000 to

40,000 ohms

Ignition Module Resistance Table

5. Check and/or adjust ignition module air gap(s). An air gap of 0.28/0.33 mm (0.011/0.013 in.) must be maintained

under all three legs of ignition module(s). Checking/adjusting should be performed with parts at room temperature.

Condition Possible Cause Conclusion

Module was not loosened or

replaced.

Ignition Module Air Gap Check that specied air gap is

present under all three legs. If gap is

correct, reinstall second mounting

screw removed earlier and recheck

gap after tightening.

Module was loosened or replaced. Ignition Module Adjust ignition module air gap.

a. Adjust ignition module air gap.

1. Turn ywheel magnet away from module position.

2. Attach module to mounting legs, pull it away from ywheel, and tighten screws to hold it temporarily.

3. Rotate ywheel so magnet is centered under module.

4. Position a 0.30 mm (0.012 in.) feeler gauge between magnet and all three legs of module. Ignition module

air gap is critical to proper system performance. Do not attempt to set it with a business card or folded

microche card. Use feeler gauge specied.

5. Loosen mounting screws, allow magnet to pull module down against feeler gauge, and retighten mounting

screws.

6. Rotate ywheel to remove feeler gauge, position magnet back under module, and recheck that specied

gap, minimum of 0.28 mm (0.011 in.), exists under each leg of module. When you are certain gap is correct,

torque module mounting screws to 4.0 N·m (35 in. lb.). Repeat these 6 steps to set other ignition module.

6. Reattach lead wires to ignition module(s), noting if resistance is felt, indicating a snug t between male and female

terminals. If any connections do not feel snug, disconnect lead, lightly pinch female terminal with a pliers, and

recheck t.

7. When integrity of all connections has been veried, retest for spark.

Loading...

Loading...