Governor System

30 24 690 06 Rev. KKohlerEngines.com

Sensitivity Adjustment

Governor sensitivity is adjusted by repositioning

governor spring in holes of governor lever. If speed

surging occurs with a change in engine load, governor

is set too sensitive. If a big drop in speed occurs when

normal load is applied, governor should be set for

greater sensitivity and adjust as follows:

1. To increase sensitivity, move spring closer to

governor cross shaft.

2. To decrease sensitivity, move spring away from

governor cross shaft.

ELECTRONIC GOVERNOR

Electronic governor regulates engine speed at varying

loads. Typical electronic governor includes:

● Digital linear actuator.

● Throttle linkage.

● Linkage spring.

● Choke linkage.

● Throttle lever adapter.

● Governor Control Unit.

Digital Linear Actuator (DLA)

Energizing bi-directional digital linear actuator coils in

proper sequence, causes threaded shaft to move out

of, or back into rotor, in precise linear increments. When

power is removed, actuator shaft remains in position.

DLA must initialize (fully extend) to move throttle plate to

closed position, and partially open for starting. Correct

adjustment of DLA is critical to achieve full range of

throttle plate movement. See Adjustment.

Governor control unit (GCU) senses engine speed

by pulse voltage inputs from ignition modules. GCU

regulates engine speed by variable input voltage from a

customer-supplied potentiometer or a single pole, single

throw (SPST) switch.

NOTE: Actual speeds depend on application. Refer to

equipment manufacturer’s recommendations.

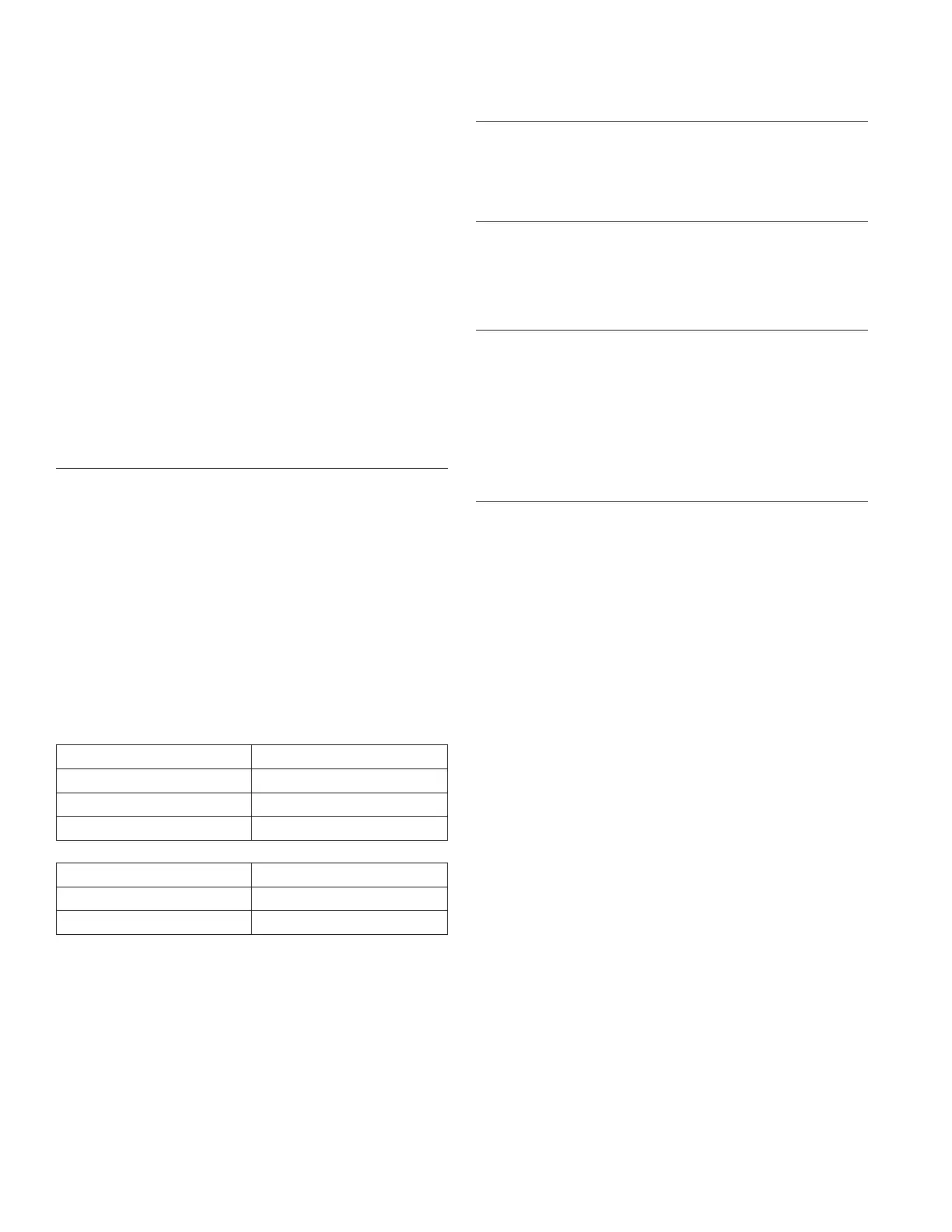

Potentiometer Specifi cations

Wiper Voltage Engine Speed (RPM)

0-1 Low Speed Endpoint

1-9 Variable Speed Endpoint

9-16 High Speed Endpoint

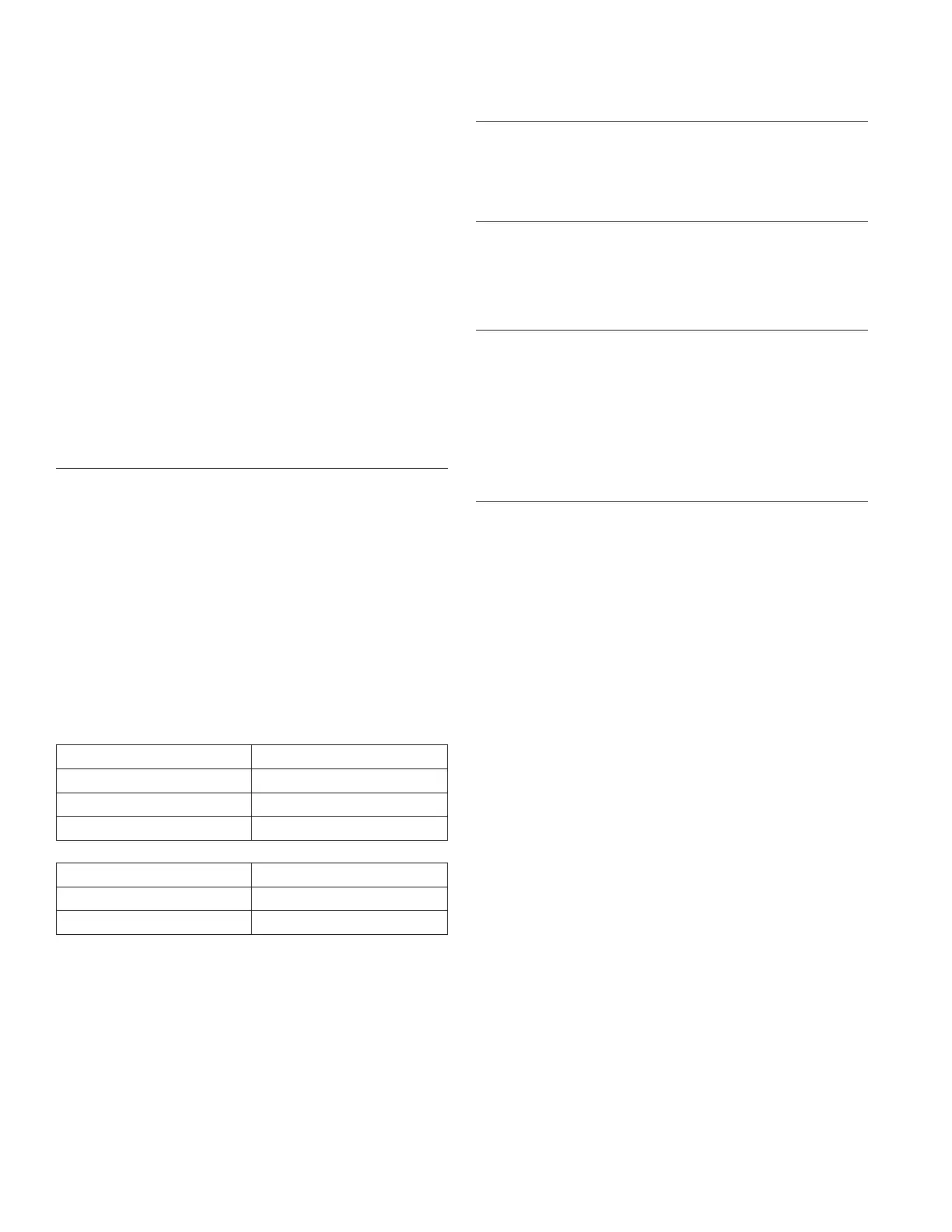

SPST Switch Specifi cations

Switch Position Engine Speed (RPM)

Open Low Speed Endpoint

Closed High Speed Endpoint

GCU Safety Features

In event of an engine overspeed condition, GCU will shut

down engine by grounding ignition modules.

GCU will shut down engine by grounding ignition when

power to GCU is lost.

Linkage

Throttle linkage spring will fully open throttle plate if

linkage becomes detached from DLA. This will create an

overspeed condition causing engine to shut down. DLA

shaft will have to be manually screwed back into body,

and then retracted before reassembling linkage.

Adjustment

DLA must be in fully retracted position during assembly.

Full range of throttle plate movement will not be

achieved if DLA is partially extended when assembled.

Loosen DLA mounting plate screws located on top of

actuator plate. With throttle linkage centered in U-Clip or

secured with a retaining clip at end of DLA shaft, slide

DLA bracket assembly back until throttle plate is fully

open. Torque mounting plate screws to 2.5 N·m (22 in.

lb.).

Troubleshooting

Engine Starts But Will Not Continue to Run

1. Check linkage connection between DLA and throttle

plate.

2. Verify DLA initializes when power is supplied (key

switch in start or run position).

3. Test potentiometer wiper output voltage (if

equipped).

4. Test SPST switch (if equipped).

5. Check wire harness and connections.

Engine Does Not Run At Expected Speed

1. Check to see that throttle linkage and DLA have full

range of motion having no mechanical interference.

2. Test potentiometer wiper voltage (if equipped).

3. Test SPST switch (if equipped).

Loading...

Loading...