TP-7070 7/18 91Section 3 Scheduled Maintenance

3.8.10 Notched V-Belt Adjustment

(KD2000--KD3250)

For models KD2000--KD3250, use the following

procedure to adjust the tension on the six notched

V-belts which turn the fan pulley.

Note: The following content on fan bearing adjustment

does not apply to models KD800--KD1750.On

models KD800--KD1000, the fan belt tension is

self-tensioning and maintenance-free. On

Models KD1250--KD1750, the tensioner is

located on the engine. Refer to the engine

operation manual to adjust the tension.

1. Read and follow the safety precautions at the

beginning of the section.

2. Before working on the generator set or connected

equipment, remove the generator set from service.

Refer to the safety precautions for preventing

accidental starts and disabling the generator set.

a. Remove the load from the generator set.

b. Shut down the generator set.

c. Place the generator set controller into

Out-of-Service mode and press the

emergency stop button.

d. Disconnect the power to the battery charger.

e. Remove the battery cables negative (--) lead

first to disable the generator set.

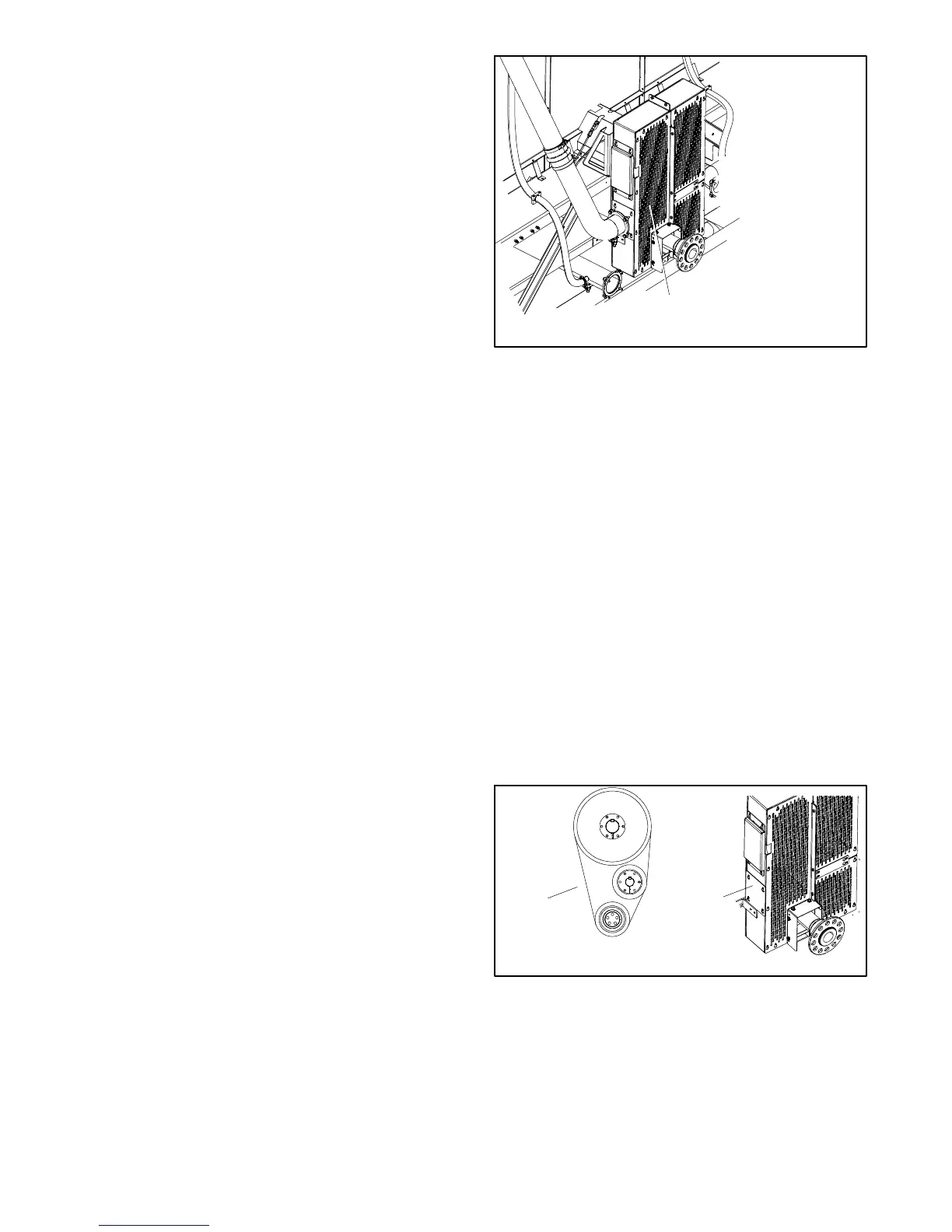

3. Remove the fan guard rear face panel. Inspect the

fan drive belt and replace if it is damaged or worn.

See Figure 3-17.

10301001101

1

1. Rear face panel

Figure 3-17 Fan Guard

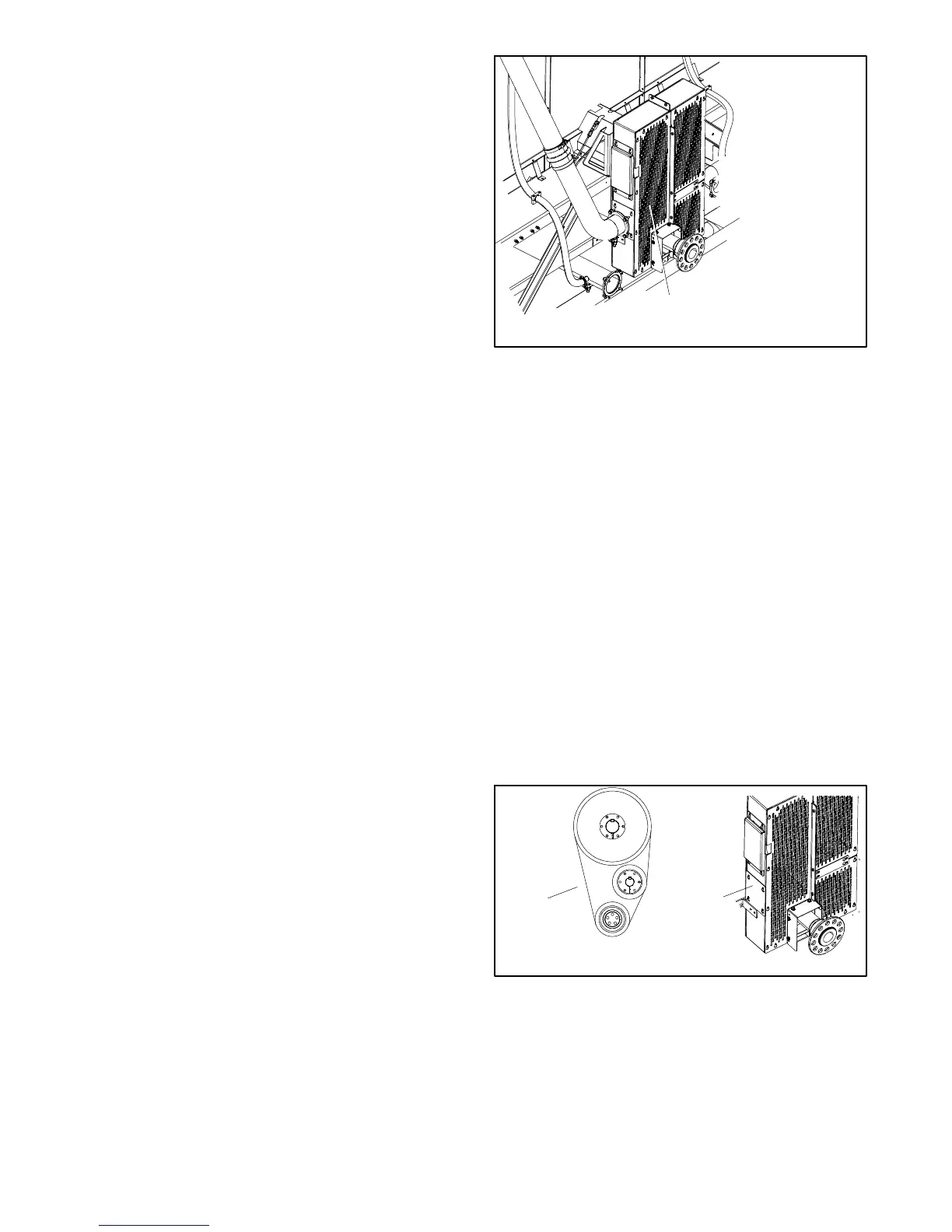

4. Check the fan belt tension and adjust, if necessary.

Set the tension by using either a sonic tension

meter or by setting the belt deflection. See

Figure 3-19.

Note: For either method, measure only a single

belt. Do not overlap multiple belts in the

measurement.

a. To adjust the tension with an sonic tension

meter, use the following procedure:

(1) Check the tension at the front and rear belt

of the fan pulley to understand alignment

characteristics. See Figure 3-18. Use a

sonic tension meter and compare the

reading to the frequency setting in

Figure 3-19.

(2) If a large deviation exists between the two

belts, then the pulleys may be misaligned.

1

1. Tension measurement location

2. Access panel

2

Figure 3-18 Tension Measurement Location

Loading...

Loading...