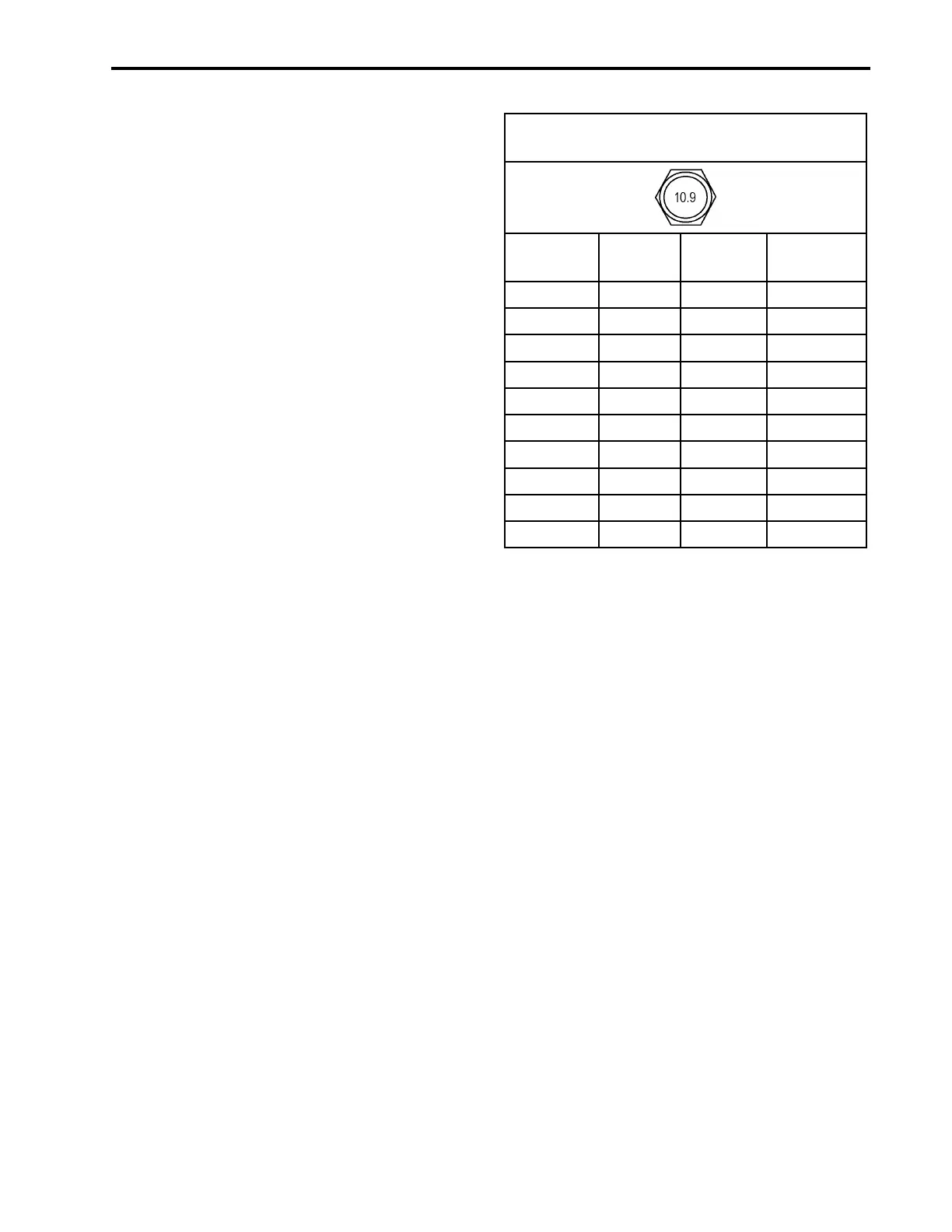

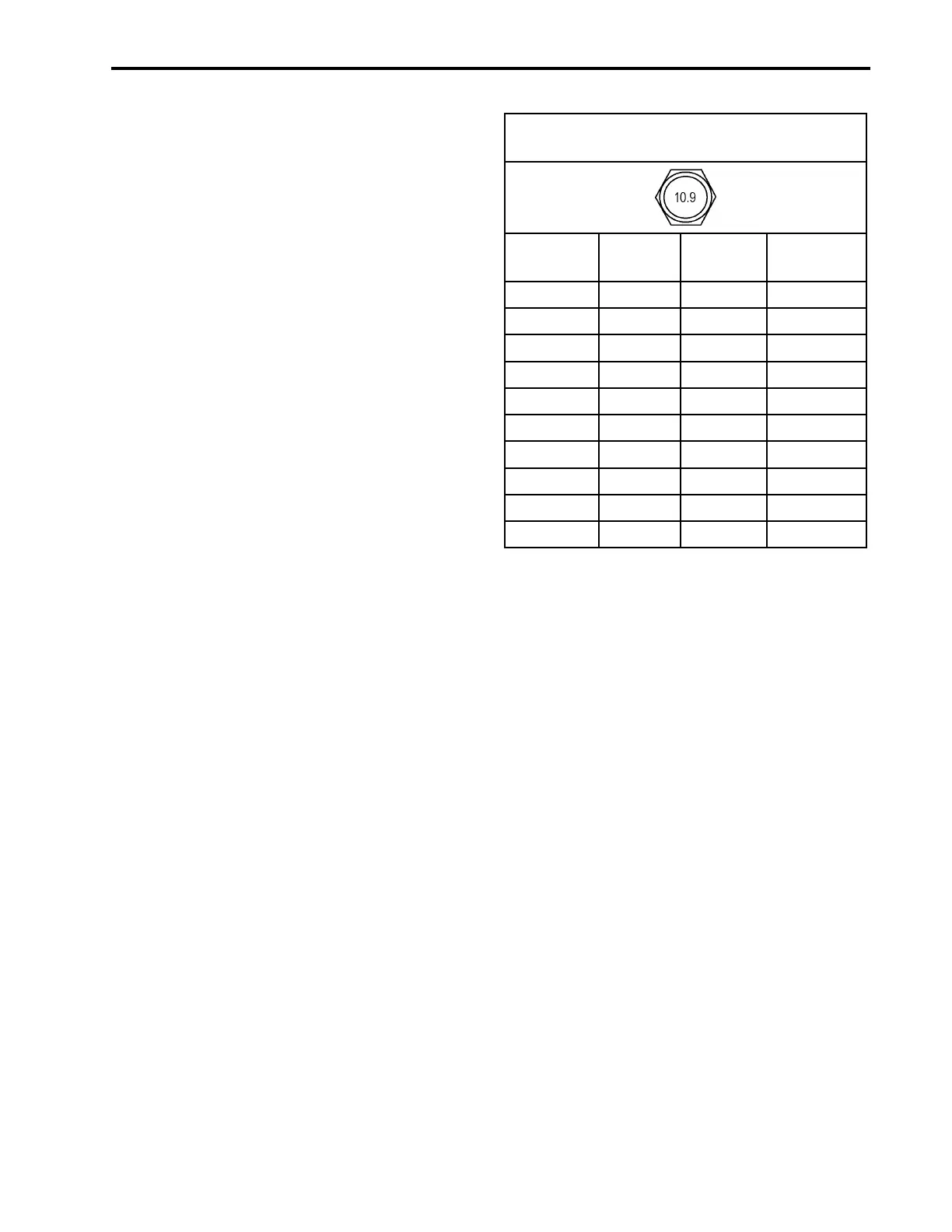

STANDARDCHARTSANDTABLESSTANDARDTIGHTENINGTORQUES

STANDARDTIGHTENING

TORQUESF .6-0000051233

Class10.9CapscrewsAndClass10Nuts

Thefollowingspecicationsapplytorequired

assemblytorquesforallmetricclass10.9nished

hexagonheadcapscrewsandclass10nuts.

DONOTlubricatecapscrewthreadsandseatsduring

assembly.Thesespecicationsarebasedonthe

followinghardware:

•Allcapscrews

•Allnuts

•Allhardenedwashersbeingphosphateandoil

coated

NOTE:Ifzinc-platedhardwareisused,eachpiece

mustbelubricatedwithsimplelithiumbasechassis

grease(multi-purposeEPNLGI)orarustpreventive

grease(seelist,thispage)toachievethesame

clampingforcesprovidedbelow.

NOTE:Torquesarecalculatedtogiveaclamping

forceofapproximately75%ofproofload.The

maximumtorquetoleranceshallbewithin±10%of

thetorquevalueshown.

Inthefollowingtableunder“CapscrewSize”,therst

numberrepresentstheshankdiameter(mm).The

secondnumberrepresentsthreadpitchinmillimeters.

Example:M20x2.25

M20=shankdiameter(20mm)

2.25=threadpitchinmillimeters

Table2-1

StandardTighteningTorqueforMetric

Class10.9Capscrews&Class10Nuts

Capscrew

Size

Torque

N·m

Torque

ft·lb

Torque

kg·m

M6x11291.22

M8x1.2530223.06

M10x1.5

55

405.61

M12x1.7595709.69

M14x215511415.81

M16x224017724.48

M20x2.2546534347.43

M24x380059081.6

M30x3.516001180163.2

M36x427502028280.5

930E-42-3

Loading...

Loading...