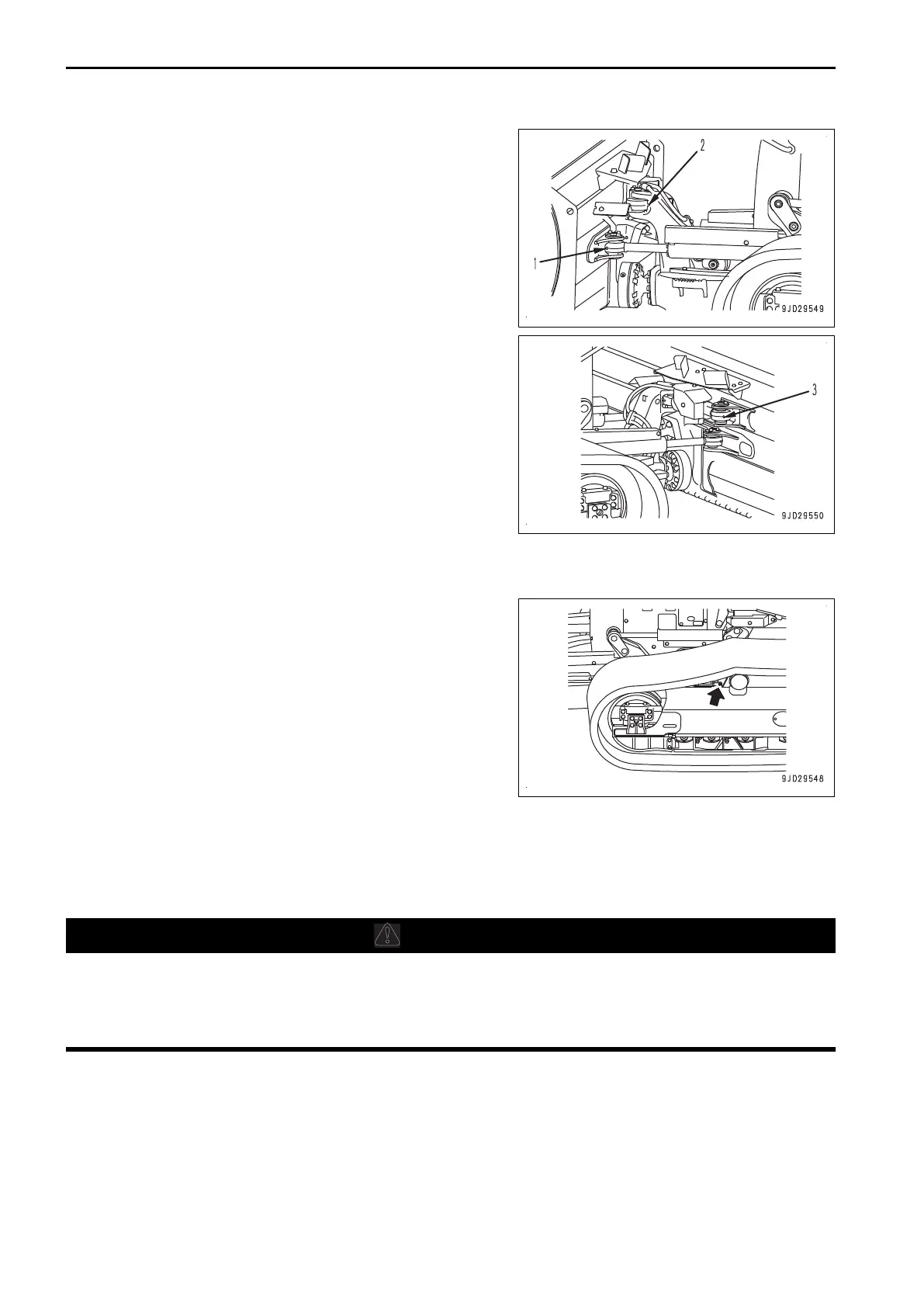

(1) Angle cylinder head pin (1 place each of right and left)

(2) T

ilt cylinder bottom pin (1 place)

(3) Tilt cylinder head pin (1 place)

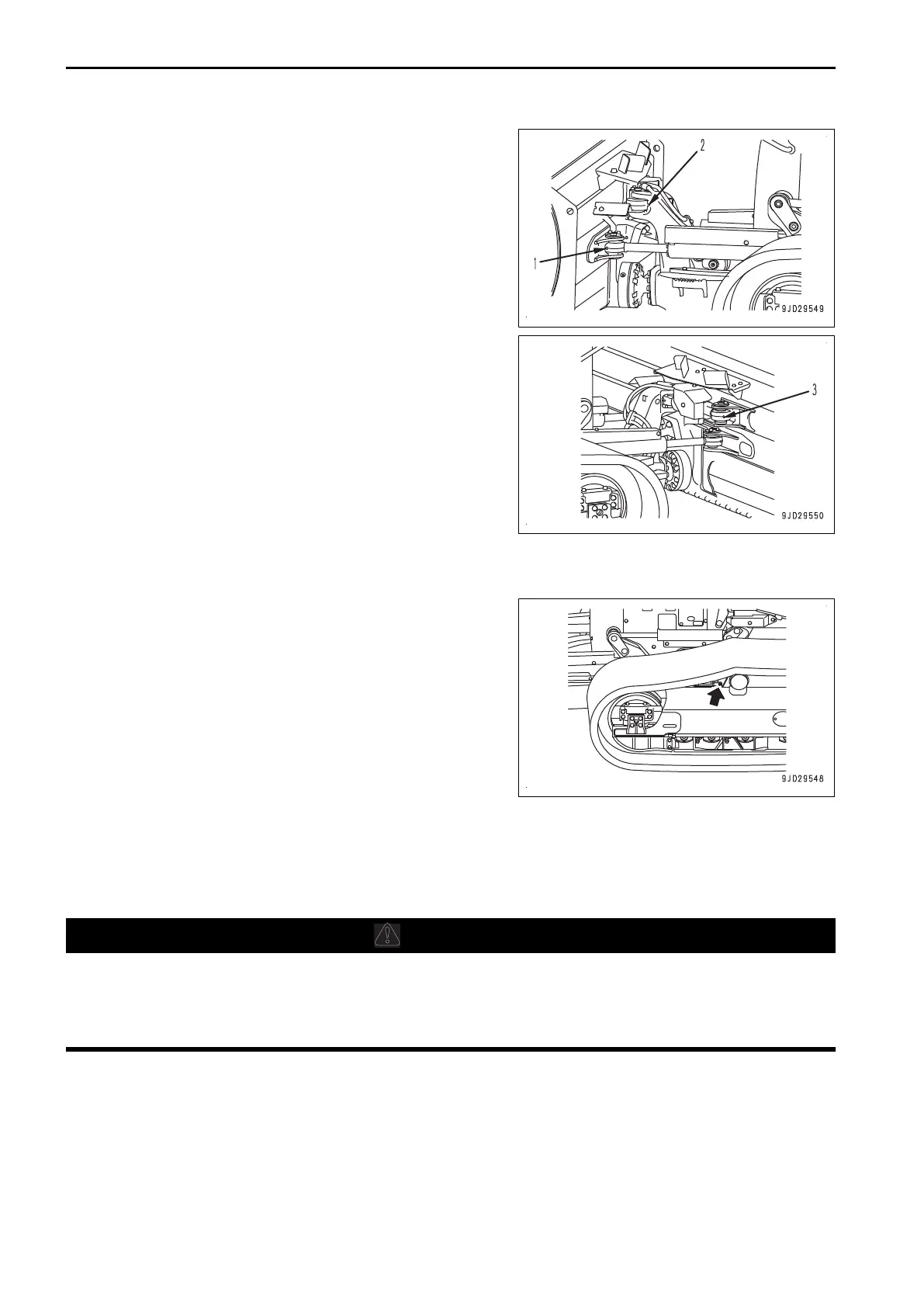

METHOD FOR LUBRICATING EQUALIZER BAR SIDE PIN

(1 place each on right and left sides)

1.

Remove all soil and sand from the top of the track frame

and top of the cover

.

2.

Clean the grease fitting shown by arrow.

3.

Supply grease by using a grease pump.

REMARK

• Supply 3 shots of grease (Operate the grease pump

lever 3 times) to each grease fitting, and check that

grease is newly discharged through the seal lip.

• If grease is not newly discharged through the lip por-

tion, continue supplying grease until it is discharged.

• If the blade is lowered to raise the idler 1 to 2 cm

from

the ground in order when performing lubrication, the

grease will fill the whole circumference of the pin.

METHOD FOR CHECKING OIL LEVEL IN FINAL DRIVE CASE, ADDING OIL

WARNING

• Immediately

after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Wait for the temperature to go down, and then start the work.

• If there is remaining pressure inside the case, the oil or plug may jump out. Loosen the plug slowly

to release the pressure.

Prepare a handle for the work.

MAINTENANCE PROCEDURE MAINTENANCE

4-44

Loading...

Loading...