MEGACHEM

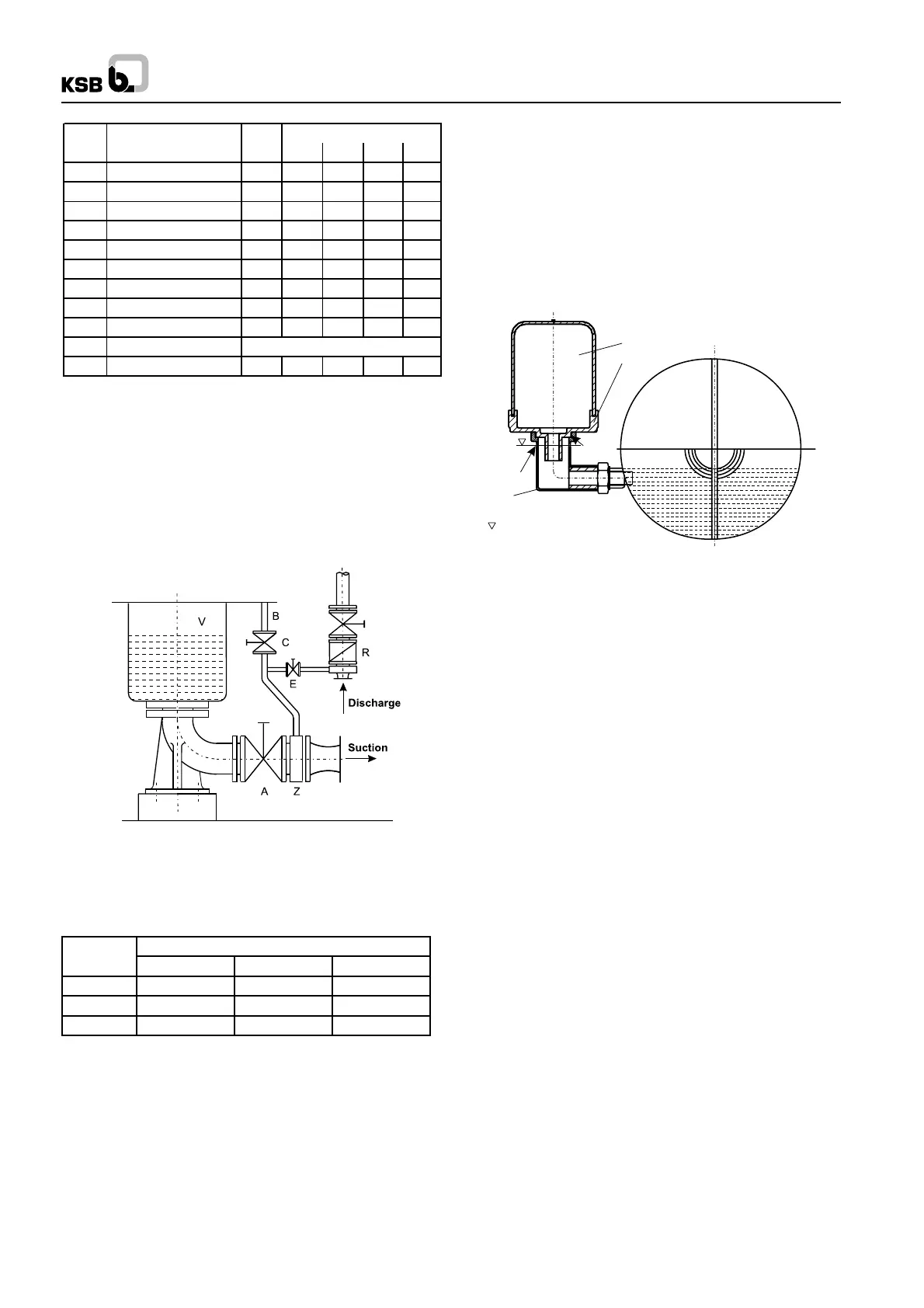

Conn. Description

onn. Bearing Bracket

Code type A-30 A-40 A-50 A-60

1M1 Pressure guage NPT 3/8" 3/8" 1/2" 1/2"

1M2 Pressure guage NPT 3/8" 3/8" 1/2" 1/2"

3M Pressure guage NPT 3/8" 3/8" 1/2" 1/2"

6D Casing drain NPT 3/8" 3/8" 1/2" 1/2"

7E Cooling inlet NPT 1/2" 1/2" 1/2" 1/2"

7S Cooling outlet NPT 1/2" 1/2" 1/2" 1/2"

8D Drain (leakage) NPT 3/8" 3/8" 3/4" 3/4"

10E External sealing in NPT 1/2" 1/2" 1/2" 1/2"

10S External sealing out NPT 1/2" 1/2" 1/2" 1/2"

13E Vent Plug

13D Plug G 1/4" 1/4" 1/4" 1/4"

Ø 20 mm

3

M 24X3

Tight fit

Reservoir

Lock nut

2 Holes

Elbow

Oil level in the bearing bracket

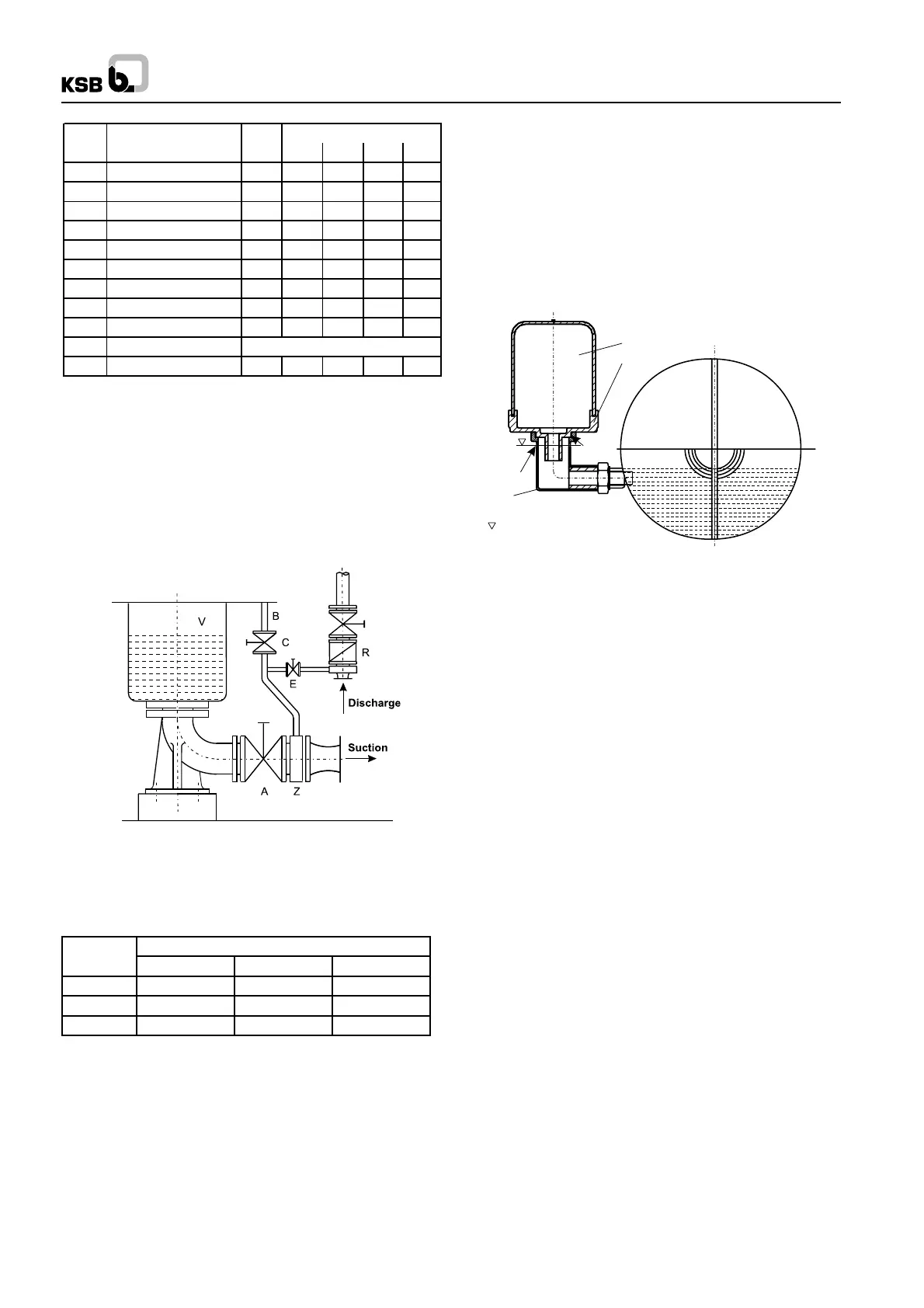

2.4.2 Vacuum balance line

If the pump has to pump from a vessel under vacuum it is

advisable to fit a vacuum balance line. This line should have a

minimum DN of 25 mm and be arranged to lead in to the

vessel above the maximum admissible liquid level.

An additional pipe line that can be shut off a pump discharge

nozzle vacuum balance line facilitates the venting of the pump

prior to start-up.

A. Main shut off valve R. Non- return valve

B. Vacuum balance line V. Vacuum vessel

C. Shutofff valve Z. Intermediate flange

E. Vacuum tight shut off valve

Fig. no. 8 : Suction line and vacuum balance line.

2.5 Coupling guard

In compliance with the accident prevention regulations, the

pump may only be operated if it is fitted with a coupling guard.

If the customer states specifically that this coupling guard is

not to be supplied by us, it must be provided by the customer

2.6 Final check

Recheck alignment as described in 2.3

It must be possible to rotate the coupling easily by hand. Check

the integrity of all connections.

3.1.1 Procedure

I Screw the constant level oiler on the bearing bracket.

II Keeping the reservoir of the oiler in upright position, lock

the elbow with the help of lock nut.

III Unscrew and remove the reservoir from its position.

IV Unscrew the vent plug on the bearing bracket and fill oil

until it appears in vertical portion of the elbow.

V Fill oil in the reservoir of oiler and screw it back in the elbow

in upright position.

VI Replace the vent plug on the bearing bracket.

VII Check after some time whether the oil level in the reservoir

is dropped or not.

It is important to fill the reservoir properly at all times.

Caution note:- The oil level should always be below the level

of vent opening of the elbow. For checking the oil level we

recommend to open drain plug and slowly drain the oil untill

the constant level oiler starts operating (i.e. untill air bubbles

are seen in the reservoir).

3.1.2 Shaft Seal

The shaft is sealed at its exit through the casing by a soft

packed stuffing box or a mechanical seal. The the change

over from gland packing execution and vice-versa is possible

by using conversion kit ( refer cl. 6.5). For details refer KSB.

3.1.3 Priming & associated checks.

Vent and prime the pump and suction line before start-up.

The shut off valve in the suction line must be completely open.

(Open the shut off valve in the vacuum line; if fitted and close

the vacuum tight shut off valve "E"; fig. no. 8)

3.1.4 Checking the direction of rotation

The direction of rotation of the prime mover must match with

the arrow on the pump. Check this by switching the motor on

and immediately switching it off again.

Mount the coupling guard.

Fig. no. 9 : Oil fill level

3 Commissioning / startup,

shutdown

3.1 Preparations

Grease lubricated bearings (standard): Grease lubricated

bearings are pre-packed with grease for life time. No greasing

is required at site.

Oil lubricated bearings (if applicable) : The bearing bracket

should be filled with oil of the types & specifications as

mentioned in 4.2.2.

Table no. : 1

Table no. 2

Start Running Standstill

A open open closed

E open closed closed

C open open closed

Valve position during

Valve

Loading...

Loading...