MEGACHEM

6

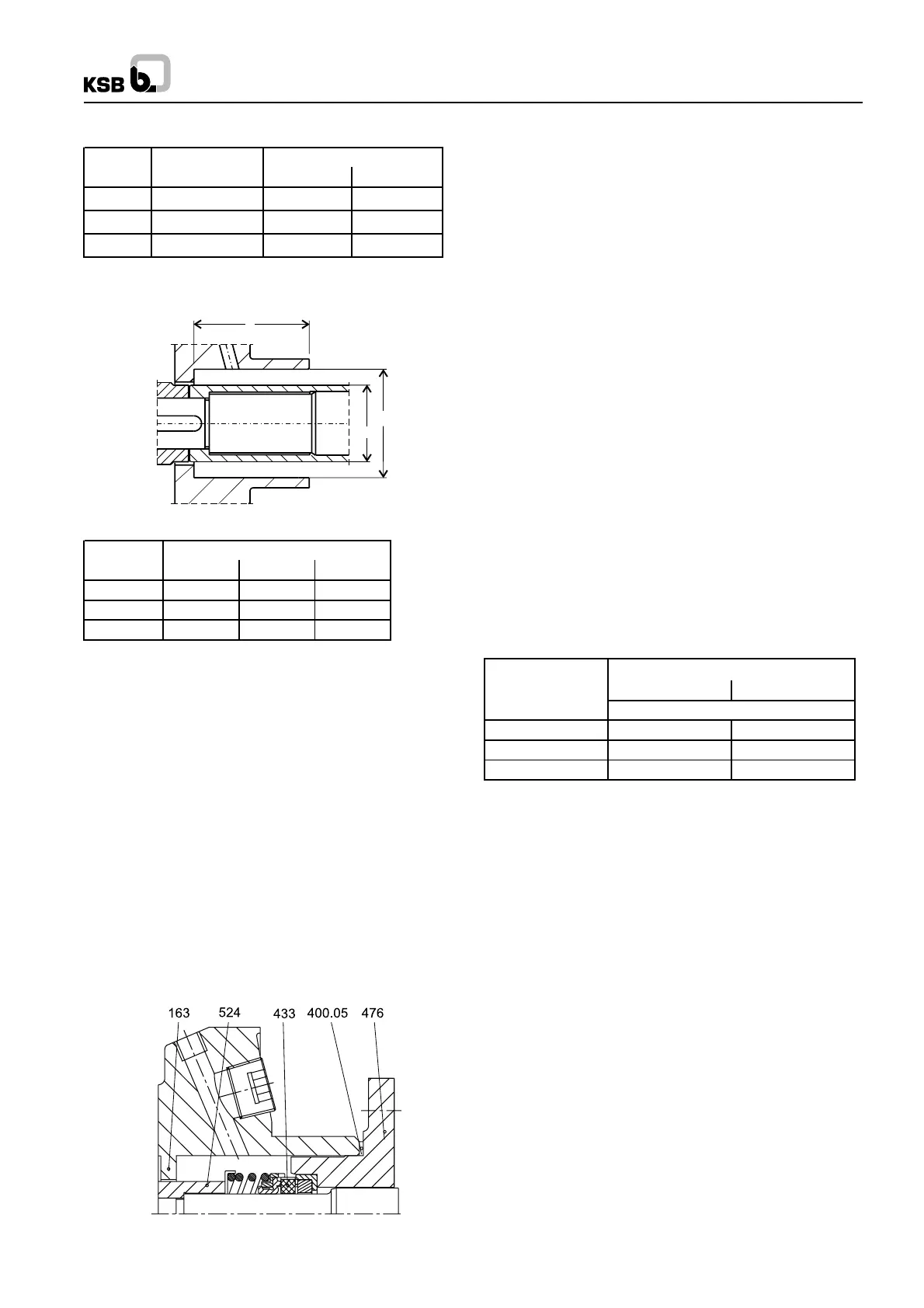

d1

l

d2

7 Cooling

For pumping liquid temperature > 105

0

C, stuffing box cooling

is required.

Pressure of cooling water 7 bar max.

Temperature of cooling water inlet 20 to 30

0

C

Temperature of cooling water outlet 50

0

C

Test pressure of cooling water 11 kg/cm

2

Clean, clear & non abrasive water is recommended for cooling

(pH7)

Bearing

Grease packed

Oil lubrication

bracket Bearing no. Bearing no. Oil qty.in ltr.

A-30 6306 2Z C3 6306 C3 0.2

A-40 6308 2Z C3 6308 C3 0.35

A-50 6310 2Z C3 6310 C3 0.65

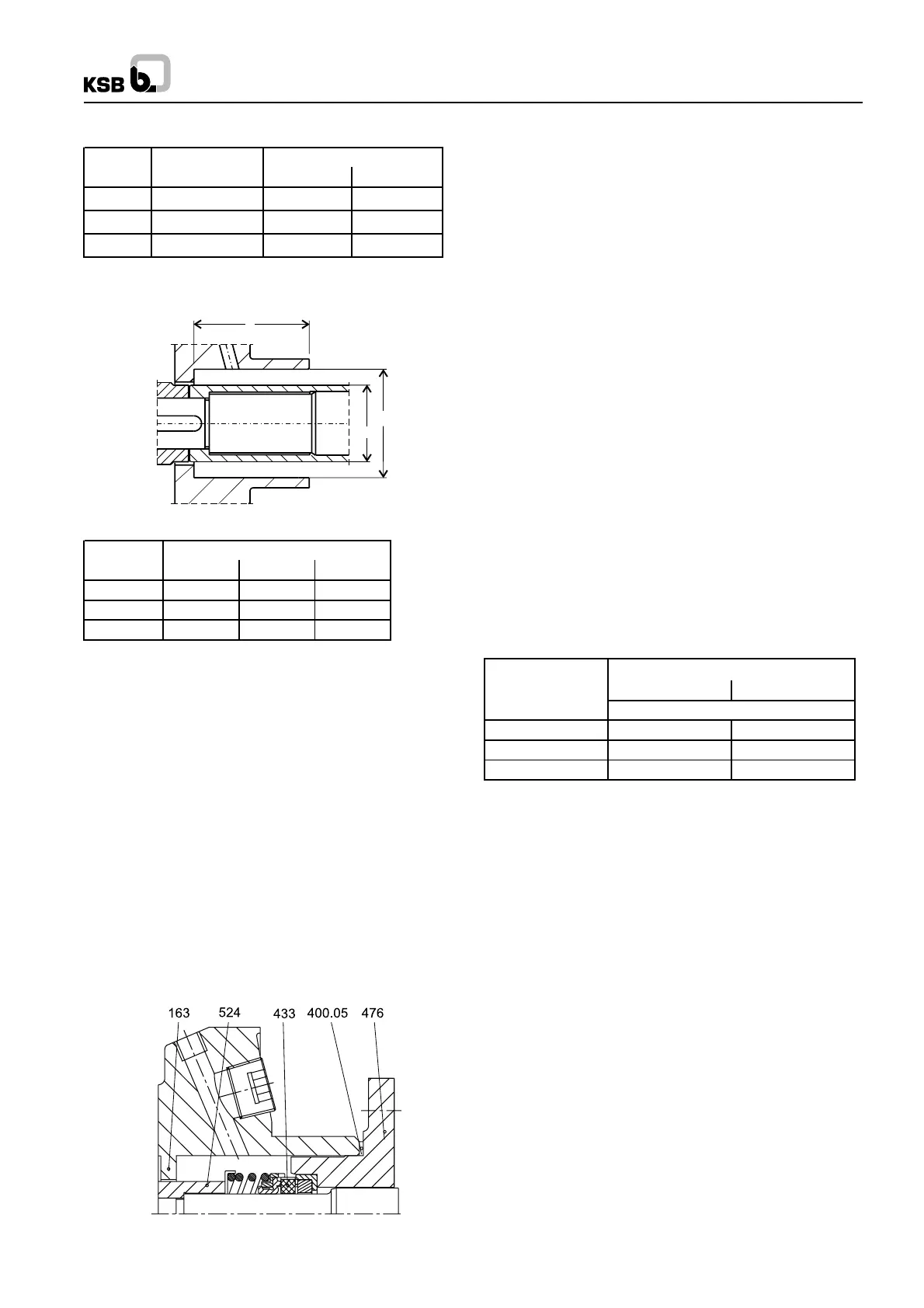

6.5 Mechanical seal

Mount the mechanical seal as described in instructions of

seal manufacturer. The following points should be observed

when mounting mechanical seal :

Extreme care and cleanliness during assembly are the

essential prerequisites for the trouble free operation of the

mechanical seal.

The guard protecting the sealing faces should only be removed

only at the time of its fitment before assembly.

When the stationary seal ring has been inserted, check its

plane parallelism in relation to the discharge cover. The surface

of the shaft protection sleeve must be absolutely clean and

smooth and mounting edge of the sleeve must be chamfered.

Before final mounting in the pump, the rubbing faces of the

mechanical seal should be wetted with a drop or two of silicon

oil.

Fig.no.15 : Mechanical seal

6.3.1 Deep groove ball bearings & lubricant fill

Table no. 5

6.4 Stuffing box compartment

Fig. no.14 : Stuffing box compartment

Table no. 6

Dimensions of packing compartment in mm.

# See interchangeability of components for co-relation of shaft &

pump sizes in table no. 8.

Bearing Dimensions

bracket # d1 d2 l

A - 30 35 55 73

A - 40 45 65 73

A - 50 60 85 91

6.6 Conversion kit

Parts required for change over from gland packing to

mechanical seal

1. Mechanical seal

2. Seal cover

3. Shaft protection sleeve

4. Stud/Nuts

5. Set of gaskets

6. Throttle bush (if required)

Parts required for change over from mechanical seal to gland

packing.

1. Shaft protection sleeve

2. Gland packing

3. Lantern ring

4. Stuffing box gland

5. Set of gaskets

6. Stud / Nut.

Table no. : 7

Up to 140 Up to 200

A-30 1.2 1.6

A-40 2.3 2.6

A-50 3 3.4

ooling water in lpm

umped media temp. in

0

Bearing bracket

Loading...

Loading...