Section 2: Operating Instructions

Table of Contents

4/5/19

AP-SRF2772, AP-SRF2790, AP-SR2772, & AP-SR2790 Powered Rakes 321-120MK

19

Section 2: Operating Instructions

Operating Checklist

Hazard control and accident prevention are dependent

upon the awareness, concern, prudence, and proper

training involved in the operation, transport, storage, and

maintenance of the Powered Rake. Therefore, it is

absolutely essential that no one operates the Powered

Rake unless they are age 16 or older and have read, fully

understood, and are totally familiar with the Operator’s

Manual. Make sure the operator has paid particular

attention to:

• Important Safety Information, page 1

• Section 1: Assembly & Set-up, page 10

• Section 2: Operating Instructions, page 17

• Section 3: Adjustments, page 20

• Section 4: Maintenance & Lubrication, page 24

Perform the following inspections before using your

Powered Rake.

Make the following inspections after attaching the

Powered Rake to the skid steer. Make certain the rake is

completely stopped before continuing.

1. Inspect skid steer safety equipment to make sure it is

in good working condition.

2. Carefully raise and lower attachment with the

Powered Rake set at the maximum angle to ensure

that the tires and other equipment on the skid steer

do not contact the rake.

3. Inspect hydraulic hoses for pinch points. Reposition

hoses if needed. For correct hose set-up, see

“Hydraulic Motor Hose Assembly” set-up instructions

on Page 11.

4. Inspect hydraulic hoses for wear, damage and

hydraulic leaks. See “Avoid High Pressure Fluids

Hazard” on page 3

. Replace damaged and worn

hoses with genuine Kubota parts.

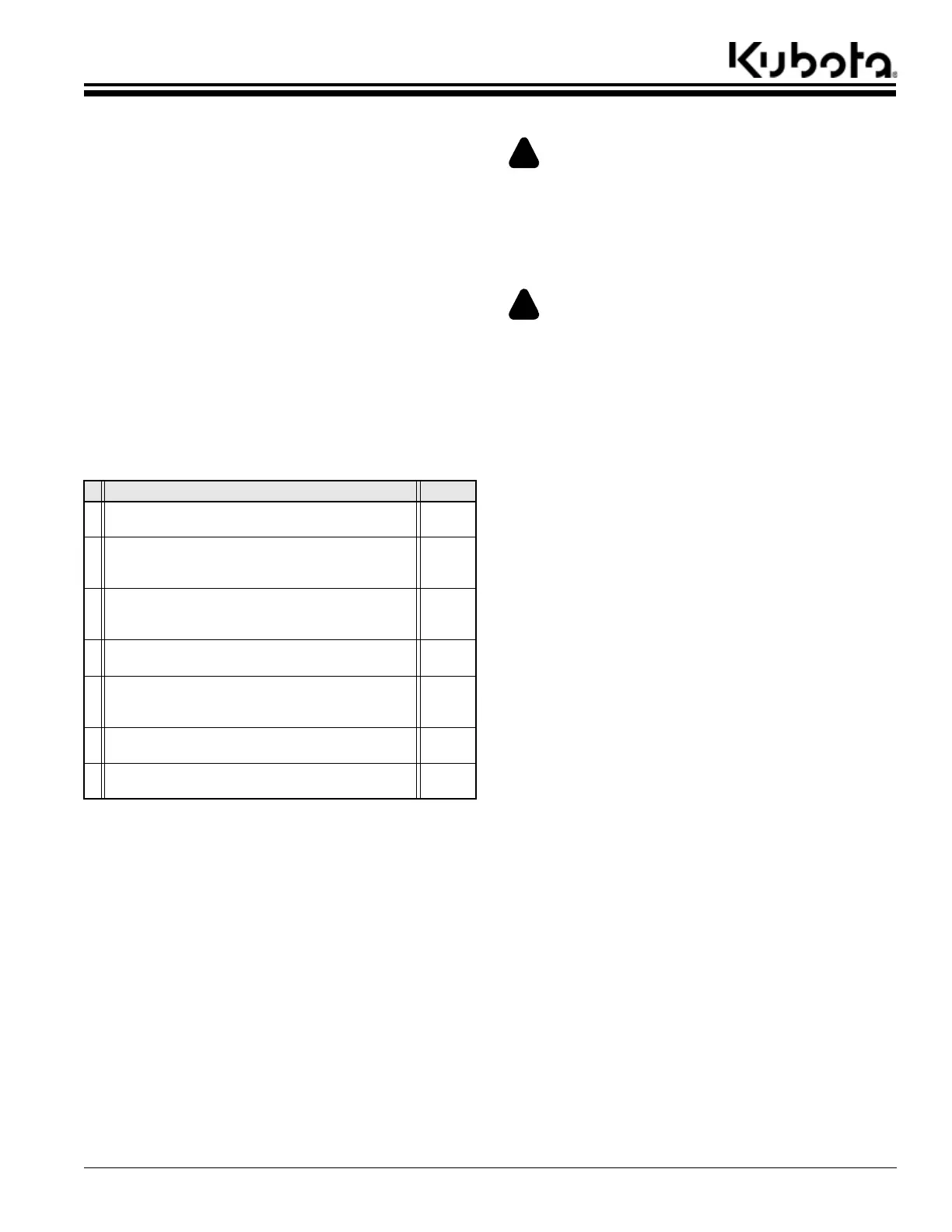

Operating Checklist

Check Page

Make sure all guards & shields are in place and

secure. Refer to “Important Safety Information”.

1

Inspect hydraulic hoses for wear, damage, and

hydraulic leaks. Replace damaged and worn

hoses with genuine Kubota parts.

3

Check initially and periodically for proper chain

tension.

Refer to “Drive Chain Inspection”.

24

Check all grease fittings. to make sure they have

been properly lubricated. Refer to “Lubrication”.

27

Check oil level in chaincase. Make certain oil

plugs are properly replaced. Refer to

“Chaincase” instructions.

28

Check initially and periodically for loose bolts

and pins. Refer to “Torque Values Chart”.

34

Check air pressure in gauge wheel tires.

Refer to “Tire Inflation Chart”.

34

Safety Information

To avoid serious injury or death:

A crushing hazard exists while hooking-up and unhooking the

attachment. Do not allow anyone to stand between attachment

and power machine while approaching or backing away from

the attachment. Do not operate lift and/or tilt controls while

someone is near the power machine and/or attachment.

To avoid serious injury or death:

• Never carry riders on the attachment or power machine.

Riders can obstruct the operator’s view, interfere with

control of the equipment, be pinched by moving

components, become entangled in rotating components, be

struck by objects, be thrown or fall from the equipment, etc.

• Always shut power machine down following the “Shutdown

Procedure” provided in this manual before leaving the

operator’s seat.

• Do not use attachment to lift, carry, push or tow other

equipment and objects. It is not properly designed or

guarded for this use. The operator could lose control and

cause a tipping hazard.

• Hydraulic fluid under high pressure can penetrate the skin

and/or eyes causing a serious injury. Wear protective gloves

and safety glasses or goggles when working with hydraulic

systems. Use a piece of cardboard or wood rather than

hands when searching for leaks. A doctor familiar with this

type of injury must treat the injury within a few hours or

gangrene may result. DO NOT DELAY.

• Do not rotate front loader hitch plate fully down. Doing so

can damage hydraulic hoses and cause high pressure fluid

leaks. Fluid under pressure can penetrate the skin and/or

eyes.

• Do not become entangled in the hydraulic hoses. Tripping

over hoses while entering or exiting the operator station can

cause serious injury or death.

• Make sure hydraulic flow to the attachment does not exceed

maximum rated flow listed in the specifications. Exceeding

maximum flow will increase rotor speed and result in a

thrown object hazard.

• Backup alarm must be in good working order to warn

others. Use a backup camera or rear-view mirror that is in

good condition to help see undesirable situations behind the

unit. Drive at a slower speed to compensate for blind spots.

• Avoid exposure to dust containing crystalline silica

particles. This dust can cause serious injury to the lungs

(silicosis). Because crystalline silica is a basic component

of sand and granite, many activities at construction sites

produce dust containing crystalline silica. Trenching,

sawing and boring of material containing crystalline silica

can produce dust containing crystalline silica.

Loading...

Loading...