38 TROUBLESHOOTING

ENGLISH

TROUBLESHOOTING

CAUTION

To avoid personal injury:

A Always perform any check at "STOP" condition except for special check in which

operation is required.

A Do not touch the charging section during operation.

A Keep your hands and body away from the rotating parts during operation.

If the machine does not function properly, use the following chart to identify and correct the cause.

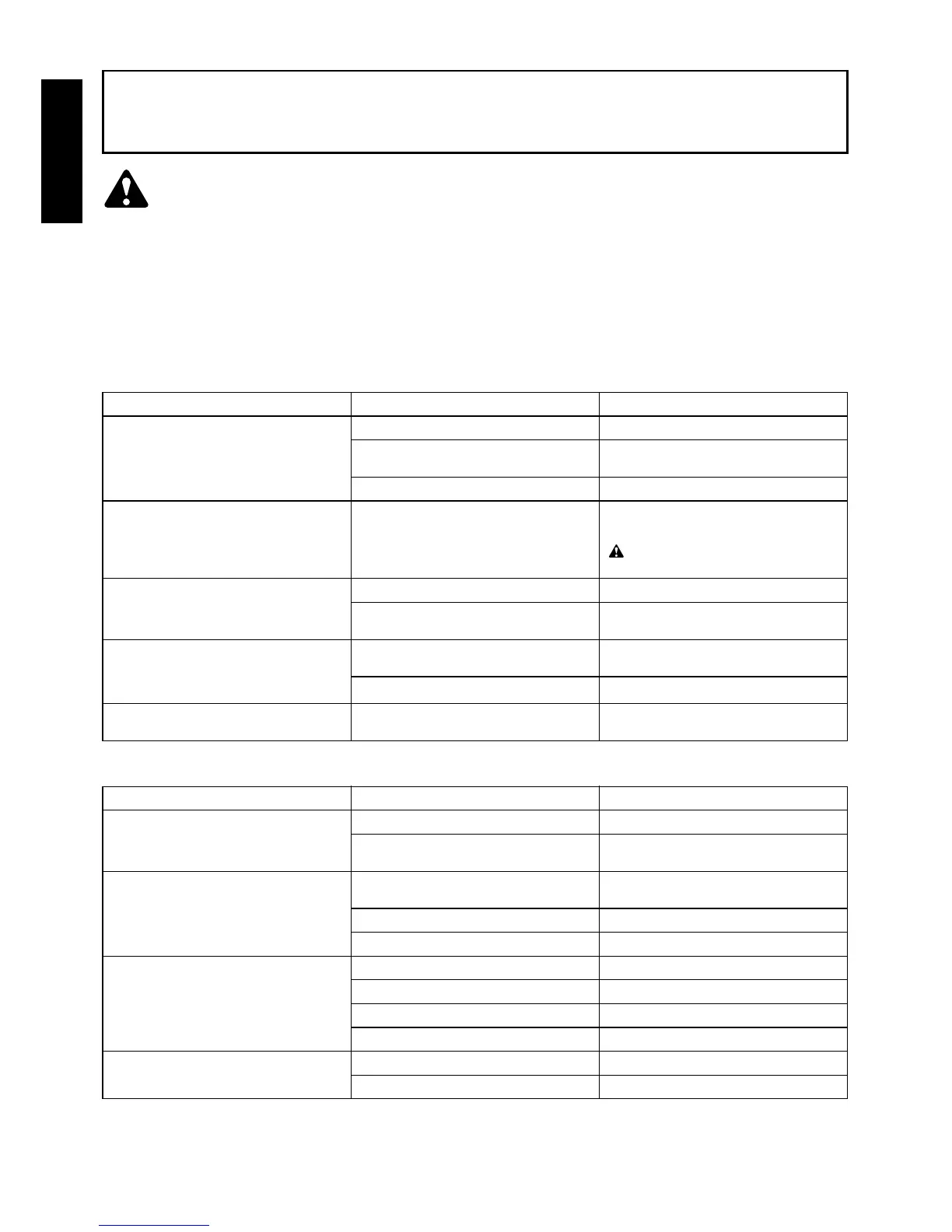

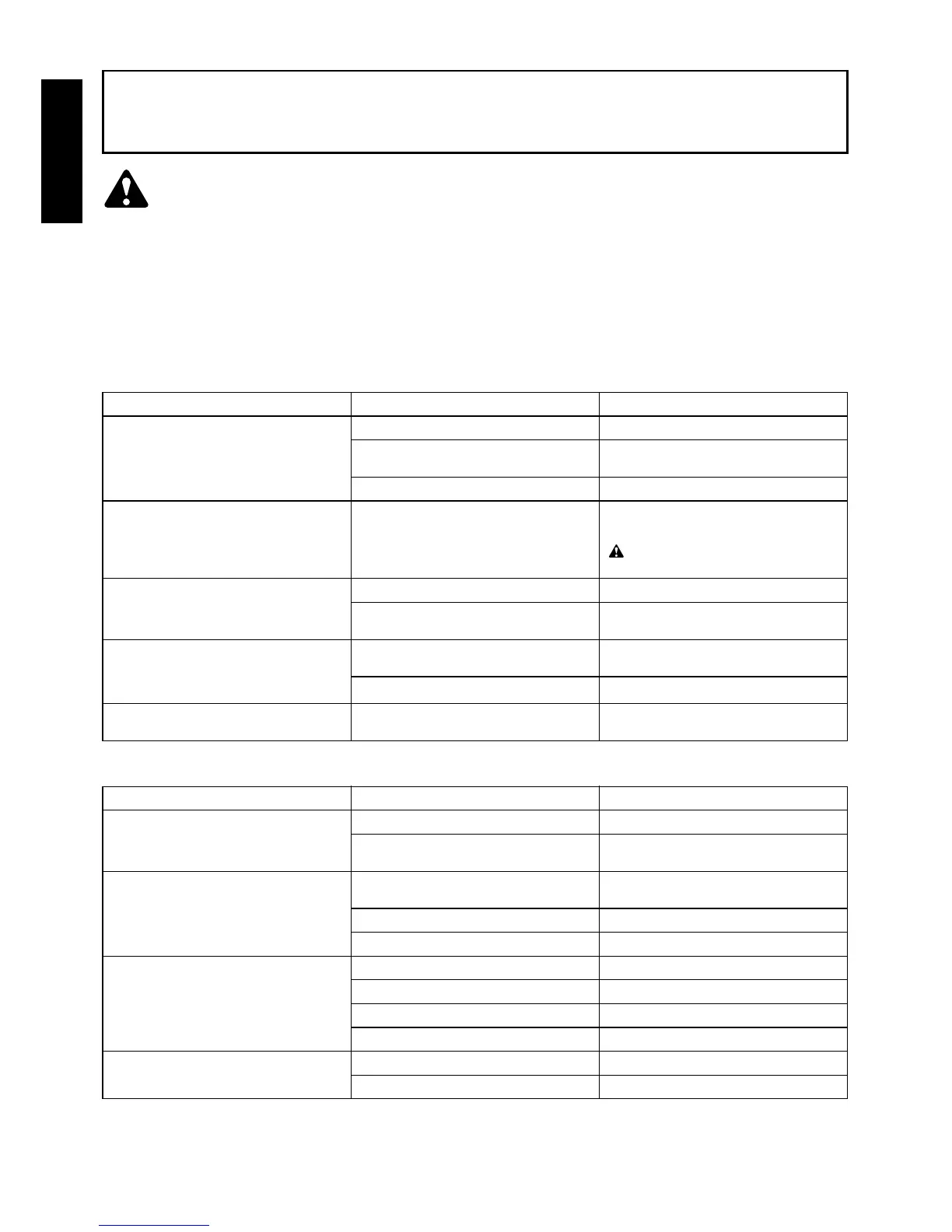

B Generator

B Easy checker

Trouble Cause Countermeasure

After electrical equipment

connected, generator does not

operate.

Circuit breaker is off. • Turn breaker "ON".

Contact of output terminal and socket is

bad.

• Reinstall.

Malfunction of electrical equipment • Request repair.

Not generating Bad contact of brush • Check, cleaning and maintenance of

contact face and contact force of brush

and slip ring.

( Danger: All works should be

performed when stopped)

Circuit breaker can not be operated. Overload • Reduce load.

Short circuit of load circuitry connected to

output section

• Repair load.

Output cannot be obtained.

• Rotation goes slow.

• Voltage drops.

• Breaker turns off.

Initial current is too much.

(e.g. motor load)

• Reduce load.

Overload • Reduce load.

Engine indicates loaded condition. Short circuit of generator wiring • Stop immediately.

Request for repair.

Trouble Cause Countermeasure

When the key is turned, the lamp

doesn't light on.

Bulb is defective. • Replace

Component or wiring defect of charging

circuit

• Check, repair

The water temperature lamp lights on

when operating.

Engine overheating. • See "Precaution overheating" in

"Radiator" section. (See page 97)

Water temperature sensor faulty. • Replace the water temperature sensor.

Water temperature sensor wiring faulty. • Repair the wiring.

The oil pressure lamp lights on when

operating.

Insufficient engine oil. • Add engine oil.

Lubricating system in trouble. • Check the system.

Oil pressure sensor faulty. • Replace the sensor.

Oil pressure sensor wiring faulty. • Repair the wiring.

The battery charge lamp lights on

when operating.

Poor contact of sub winding. • Connect tightly.

Sub winding problem. • Check the sub winding.

Loading...

Loading...