SHOP MANUAL

Paragraphs 90-91

Inspect all parts for wear, scoring or

other damage and renew as necessary.

Be sure to renew all "0" rings.

Reassemble valve by reversing

disassembly procedure. Reinstall valve

assembly using new "0" rings and

tighten mounting bolts to a torque of

24-27 N;m (18-20 ft.-lbs.). Check and ad-

just relief valve pressure as outlined in

paragraph 88.

SHUTTLE CLUTCHES

Model L355

90.

R&R OVERHAUL. To remove

shuttle transmission, tractor must first

be split between engine and clutch hous-

ing as outlined in paragraph 64. Remove

steering wheel, instrument panel, fuel

tank and support assembly and steering

gear assembly. Remove hydraulic pipe

from shuttle valve and disconnect clutch

rod from clutch release lever. Support

transmission housing and clutch housing

separately, then remove clutch housing

mounting bolts. Separate clutch housing

from transmission housing.

To disassemble shuttle transmission,

remove set screw (7-Fig. 122) and

mounting cap screws from gearcase (6).

Use two jackscrews to lift gearcase from

clutch housing. Remove reverse idler

shaft (5), gear (4) and bearings from

gearcase. Remove shuttle control valve

and valve spacer block. Remove moun-

ting cap screws from hydraulic manifold

(1-Fig. 123), then use two jackscrews

to lift manifold off clutch housing. Screw

two cap screws into upper and lower

shaft seal retainers (2-Fig. 124), then

pull retainers out of housing. Remove

seal rings (4) and snap ring

(5),

then tap

shafts rearward to remove clutch

assemblies. Remove cap screws from

mainshaft bearing case (4-Fig. 123),

then withdraw mainshaft assembly from

clutch housing. Remove snap ring (11)

and gear (9), then tap mainshaft out of

bearing case.

Disassembly procedure is the same for

either clutch pack. Remove retaining

ring (9-Fig. 124), gear (10) and inner

race (11), then separate clutch shaft

assembly from clutch pack. Remove

snap ring (31), then tap clutch shaft (23

or 24) out of bearings and gear (27 or

28).

Remove snap ring (21) and remove

back-up plate (20), clutch discs (19) and

steel plates (18) from clutch case (12).

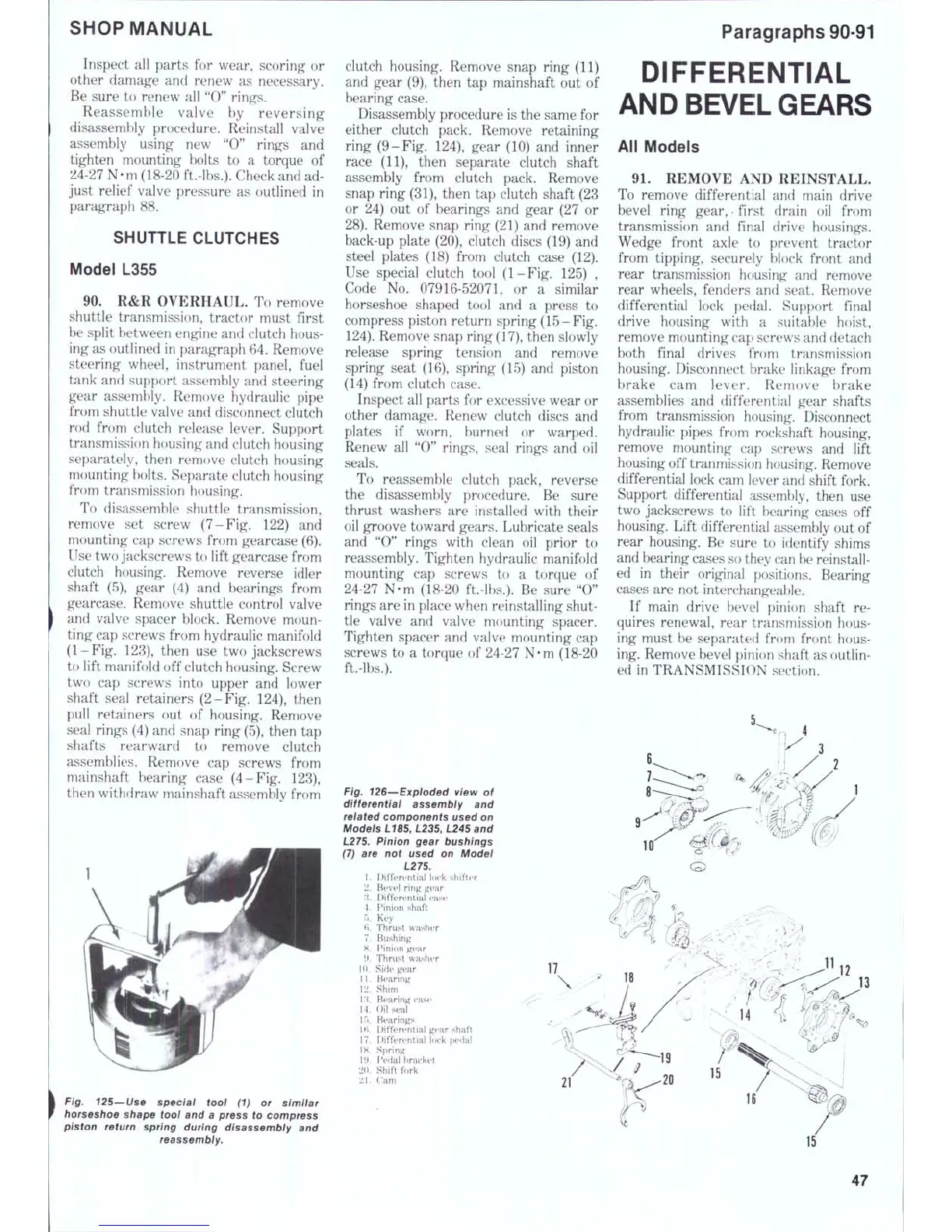

Use special clutch tool (1-Fig. 125) ,

Code No. 07916-52071, or a similar

horseshoe shaped tool and a press to

compress piston return spring (15-Fig.

124).

Remove snap ring

(17),

then slowly

release spring tension and remove

spring seat (16), spring (15) and piston

(14) from clutch case.

Inspect all parts for excessive wear or

other damage. Renew clutch discs and

plates if worn, burned or warped.

Renew all "0" rings, seal rings and oil

seals.

To reassemble clutch pack, reverse

the disassembly procedure. Be sure

thrust washers are installed with their

oil groove toward gears. Lubricate seals

and "0" rings with clean oil prior to

reassembly. Tighten hydraulic manifold

mounting cap screws to a torque of

24-27 N-m (18-20 ft.-lbs.). Be sure "0"

rings are in place when reinstalling shut-

tle valve and valve mounting spacer.

Tighten spacer and valve mounting cap

screws to a torque of 24-27 N-m (18-20

ft.-lbs.).

DIFFERENTIAL

AND BEVEL GEARS

All Models

91.

REMOVE AND REINSTALL.

To remove differential and main drive

bevel ring gear,

-

first drain oil from

transmission and final drive housings.

Wedge front axle to prevent tractor

from tipping, securely block front and

rear transmission housing and remove

rear wheels, fenders and seat. Remove

differential lock pedal. Support final

drive housing with a suitable hoist,

remove mounting cap screws and detach

both final drives from transmission

housing. Disconnect brake linkage from

brake cam lever. Remove brake

assemblies and differential gear shafts

from transmission housing. Disconnect

hydraulic pipes from rockshaft housing,

remove mounting cap screws and lift

housing

ofT

tranmission housing. Remove

differentia] lock cam lever and shift fork.

Support differential assembly, then use

two jackscrews to lift bearing cases off

housing. Lift differential assembly out of

rear housing. Be sure to identify shims

and bearing cases so they can be reinstall-

ed in their original positions. Bearing

cases are not interchangeable.

If main drive bevel pinion shaft re-

quires renewal, rear transmission hous-

ing must be separated from front hous-

ing. Remove bevel pinion shaft as outlin-

ed in TRANSMISSION section.

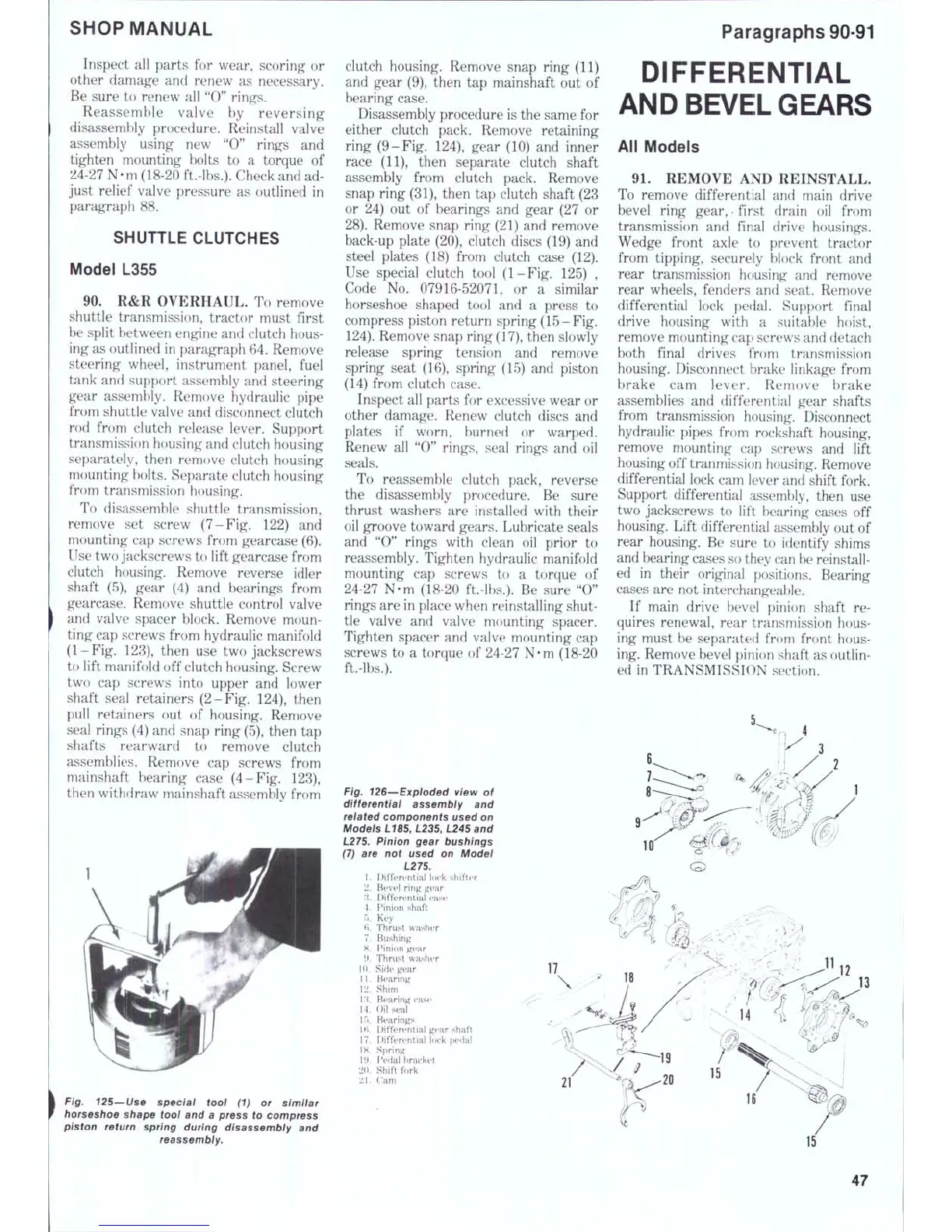

Fig. 126—Exploded view of

differential assembly and

related components used on

Models L185, L235, L245 and

L275. Pinion gear bushings

(7) are not used on Modei

L275.

1.

Differential lock shifter

2.

Bt'Vt'I ring gear

.'{.

Differential case

4.

Pinion shaft

r.. Key

f;. Thrust washer

7.

Bushing

8. Pinion gear

i>.

Thrust washer

10.

Side gear

11.

Bearing

12.

Shim

I'i. Bearing case

14.

Oil seal

15.

Bearings

16.

Differential gear shaft

17.

Differential lock pedal

18.

Spring

19.

Pedal bracket

20.

Shift fork

21.

Cam

Fig. 125—Use speciai tool (1) or simiiar

horseshoe shape tool and a press to compress

piston return spring during disassembly and

reassembly.

21

47

Loading...

Loading...