2RV/2RW/2RX/2RY/3RA-3

7-24

7-2 Feeding/Conveying Failures

(1) Prior standard check items

Content of Feeding/Conveying Failures

(1-1) Paper jam due to the cover-open detection

No. Contents

(1-1) Paper jam due to the cover-open detection

(1-2) Paper jam due to the wave or curl in the fuser section of the damp paper

(1-3) Paper jam due to dog-ear, skew, crease. fusing failure, curl, etc.

(1-4) Paper jam due to the guide factor

(1-5) Paper jam due to paper loading failure at the paper source

(1-6) Paper jam due to the inferior paper

(1-7) Paper jam caused by conveying rollers and pulleys

(1-8) Paper jam due to the sensor

(1-9) Paper jam due to setting failure or detection failure

(1-10) Paper jam due to the static electricity

(1-11) Paper jam due to paper storage environment (high humidity)

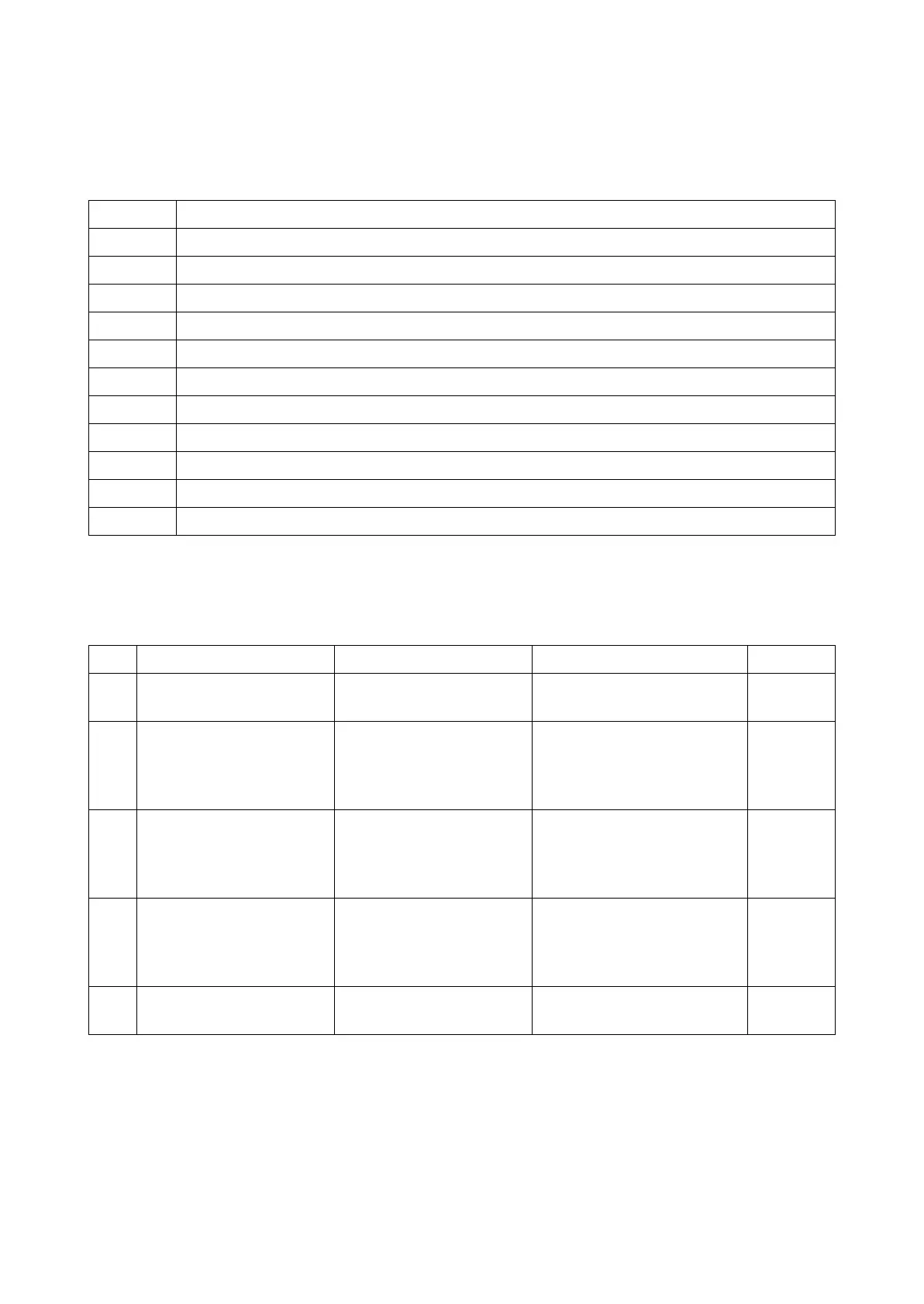

Step Check description Assumed cause Measures Reference

1 Opening / closing the front

cover

The front cover is not

engaged.

Open/close the front cover.

2 Re-loading / replacing

paper

The paper fanning is not

enough or the cutting edge

of loaded paper is dam-

aged.

Fan the paper well and re-

load paper after switching top

and bottom ends. If the paper

is folded, correct or replace it.

3 Re-loading paper The paper is wavy. Correct or replace paper. If

difficult to replace, re-load

paper by switching top and

bottom ends or turning it over.

4 Checking the paper Paper out of specification

is used or foreign objects

adhere to paper.

Ask a user to use the speci-

fied paper type. Or, remove

the paper with foreign

objects.

5 Re-loading paper The paper is not properly

loaded.

Reload paper in the cassette.

Loading...

Loading...