2HL/2HM/2HN

1-4-30

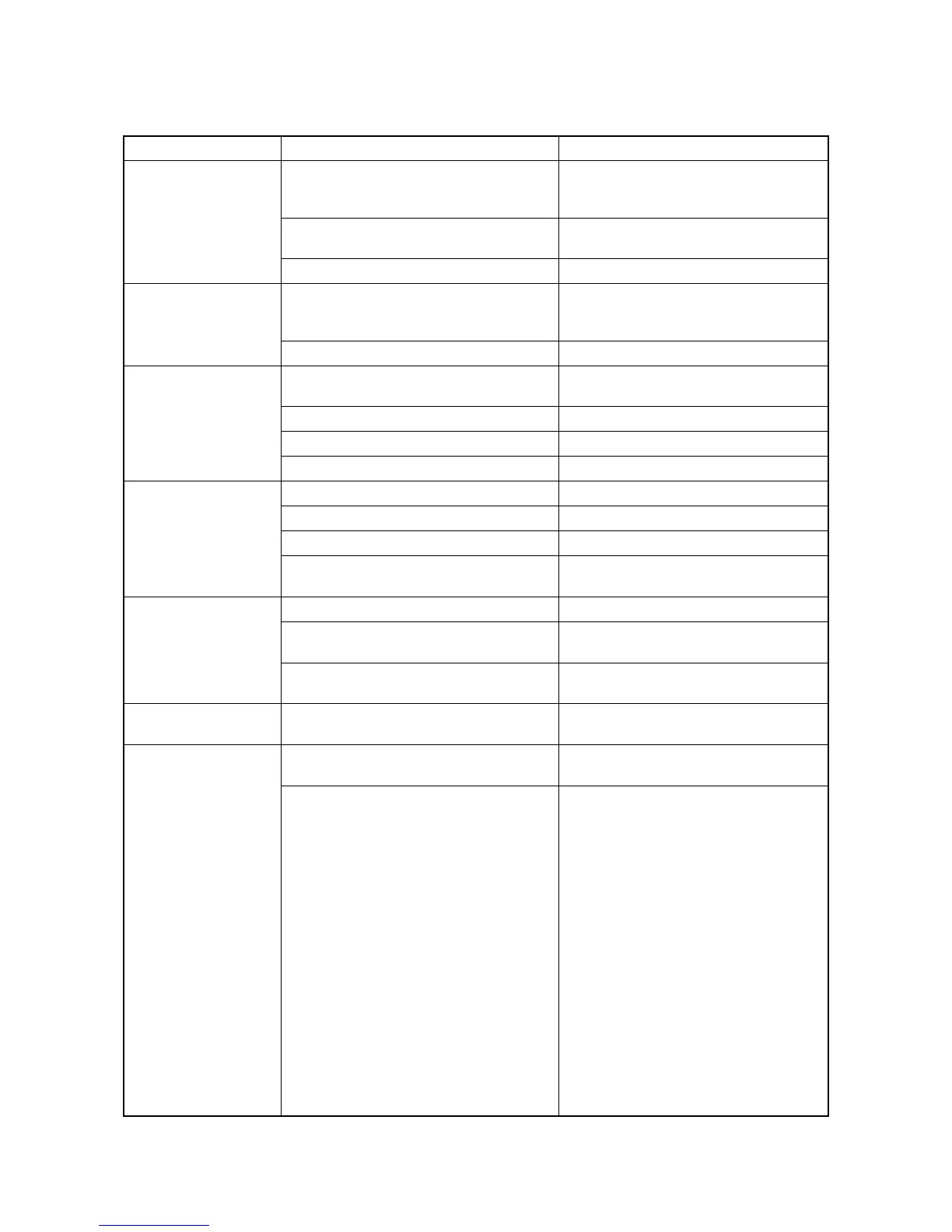

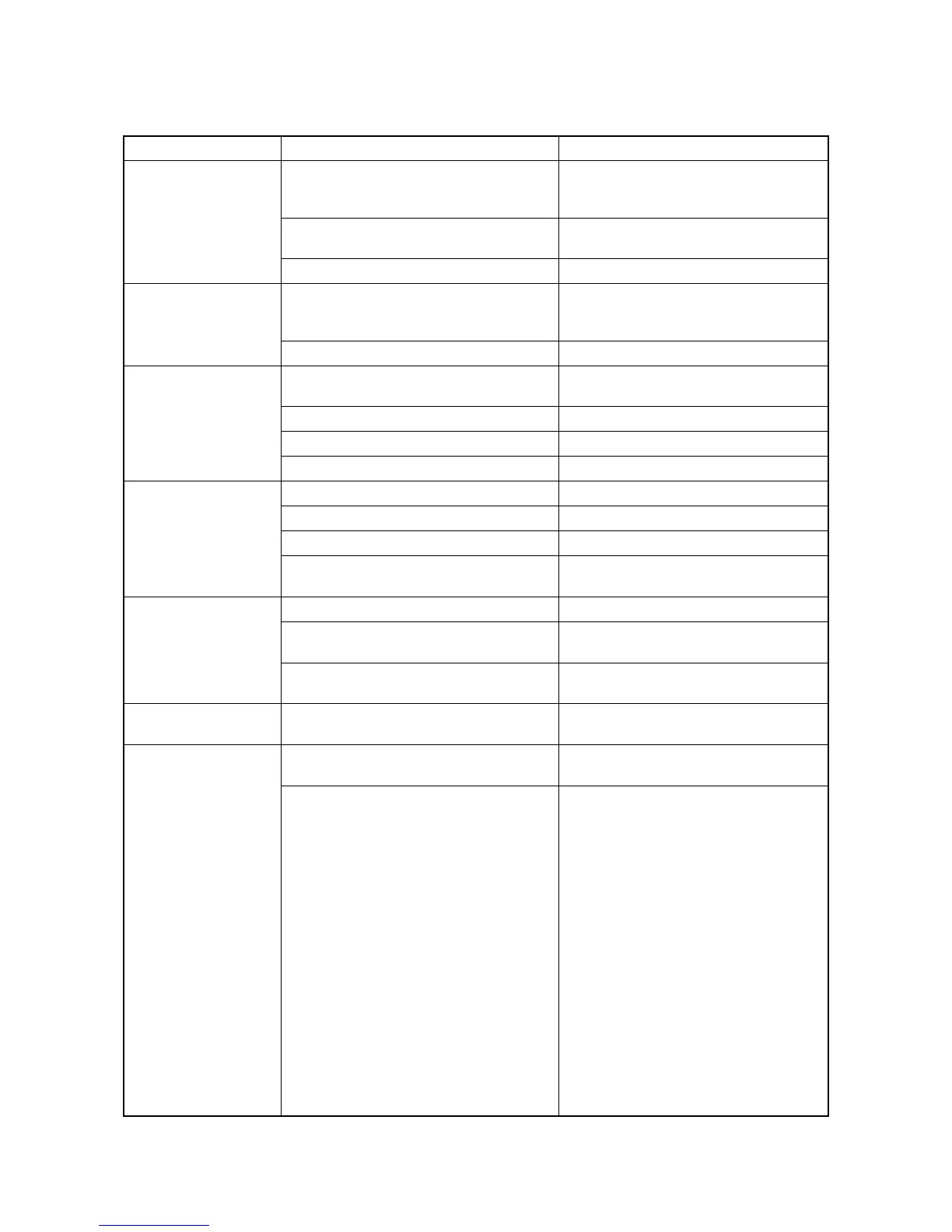

1-4-5 Mechanical problems

Problem Causes/check procedures Corrective measures

(1)No primary paper

feed.

Check if the surfaces of the paper feed roller,

MP paper feed roller are dirty with paper pow-

der.

Clean with isopropyl alcohol.

Check if the paper feed roller, MP paper feed

roller are deformed.

Check visually and replace any deformed

rollers (See page 1-5-8 and 1-5-12).

Defective paper feed clutch installation. Check visually and remedy if necessary.

(2)No secondary paper

feed.

Check if the surfaces of the upper and lower

registration rollers are dirty with paper pow-

der.

Clean with isopropyl alcohol.

Defective registration clutch installation. Check visually and remedy if necessary.

(3)Skewed paper feed. Width guide in a cassette installed incorrectly. Check the width guide visually and correct

or replace if necessary.

Deformed width guide in a cassette. Repair or replace if necessary.

XXXXXXXXXXXXXXXXXXX XXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXX XXXXXXXXXXXXXXXXXXX

(4)Multiple sheets of

paper are fed at one

time.

Check if the paper is curled. Replace the paper.

XXXXXXXXXXXXXXXXXXX XXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXX XXXXXXXXXXXXXXXXXXX

Check if the separator pad or MPF separation

pad (duplex model only) is worn.

Replace the separator pad if it is worn.

(5)Paper jams. Check if the paper is excessively curled. Replace the paper.

Check if the contact between the front and

rear registration rollers is correct.

Check visually and remedy if necessary.

Check if the heat roller or press roller is

extremely dirty or deformed.

Replace the fuser unit (See page 1-5-25).

(6)Toner drops on the

paper conveying path.

Check if the drum unit or developing unit is

extremely dirty.

Clean the drum unit or developing unit.

(7)Abnormal noise is

heard.

Check if the pulleys, rollers and gears operate

smoothly.

Grease the bearings and gears.

Check if the following electromagnetic

clutches are installed correctly:

Check visually and remedy if necessary.

Loading...

Loading...