# 48306B006 Page 13

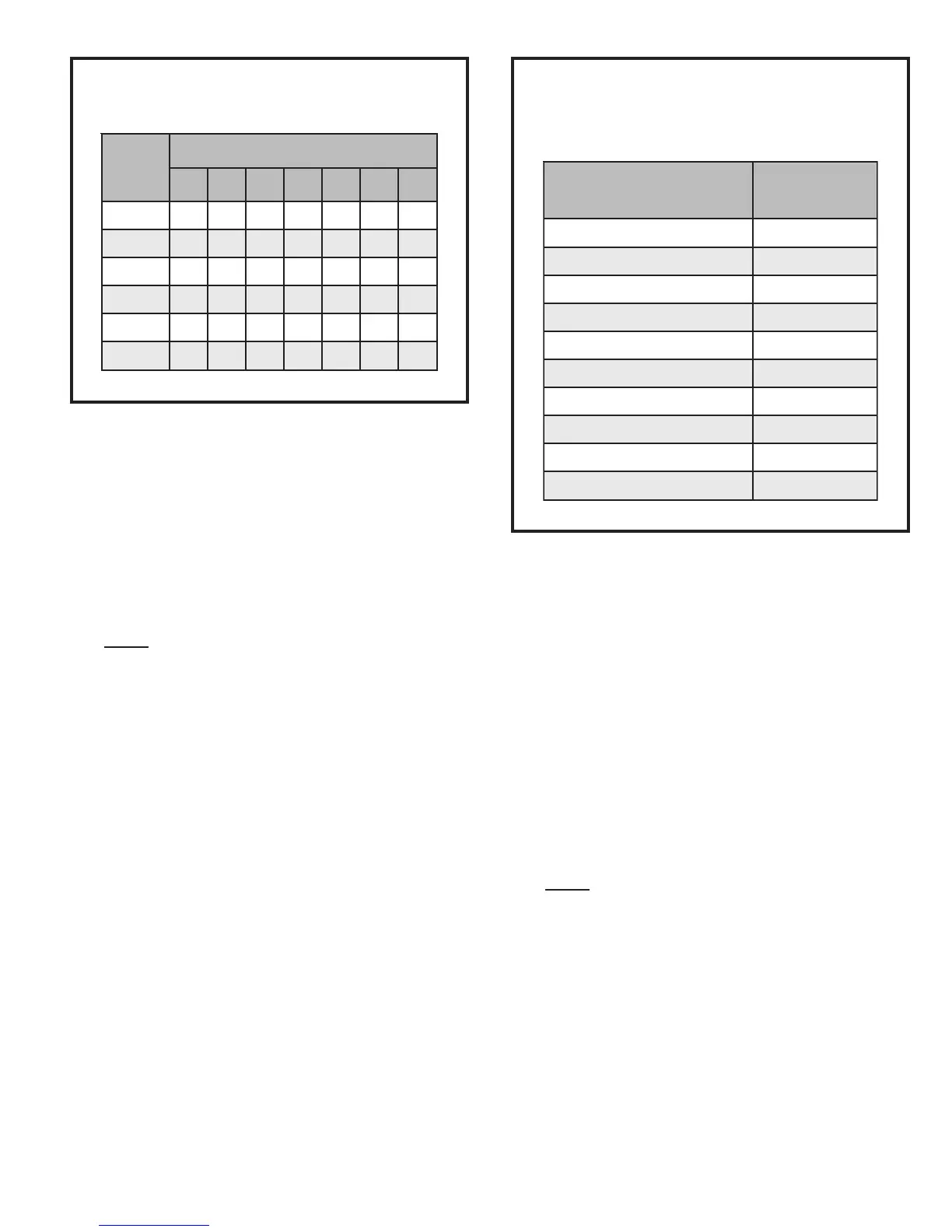

roodtuO

.pmeT

F°

)F°1±(gniloocbuSdiuqiL

81- 42- 03- 63- 24- 84- 06-

5631514131315141

57 01 31 21 01 01 31 21

588111188 1111

59 7 9 01 7 7 9 01

501 6896689

511 3 5 6 3 3 5 6

Subcooling Values for

Fixed Orifice or TXV Systems

Table 6

3. Use a temperature/pressure chart for HCFC-22 to

determine the saturation temperature for the suction

line pressure reading.

4. Subtract the saturation temperature (according to the

chart) from the suction line temperature to determine

the superheat.

_____ ° Suction Line Temperature °F

_____ ° Saturation Temperature °F

_____ ° Superheat Value °F

–

=

Pressures higher than those listed indicate that the

system is overcharged. Pressures lower than those

listed indicate that the system is undercharged. Verify

adjusted charge using the approach method.

4. Use the same digital thermometer used to check

outdoor ambient temperature in Step 1 to check liquid

line temperature. Verify the unit charge using the

approach method.

5. Subtract the outdoor ambient temperature from the

liquid line temperature to determine the approach

temperature.

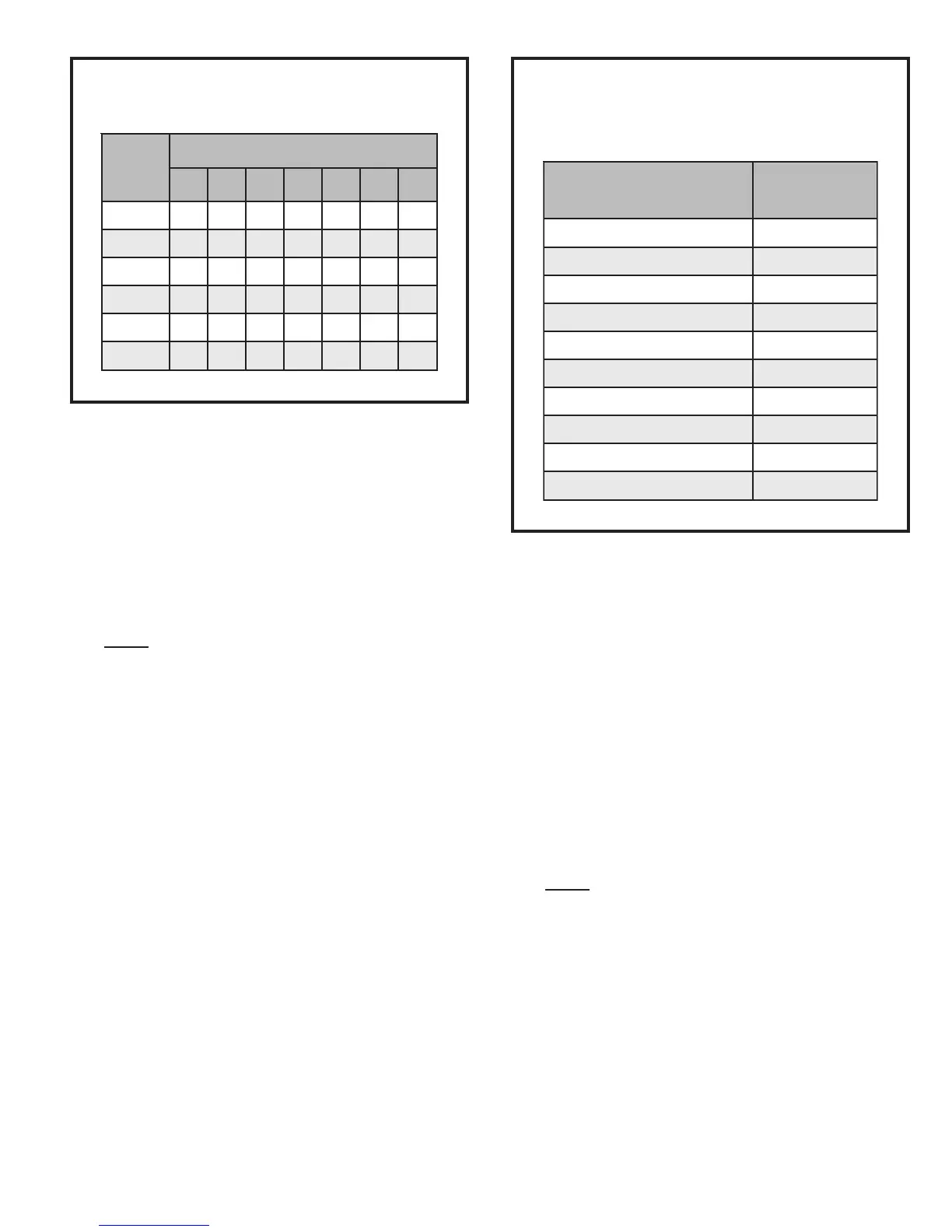

.pmeTtneibmAroodtuO

F°

taehrepuS

F°

0683

56 53

0703

57 62

0822

58 81

0921

59 8

0015

501 0

Superheat Values for

Fixed Orifice Systems

(80°DB/67°WB Return Air)

Table 7

5. Compare the superheat value with those shown in

Table 7. If superheat is greater than shown, add some

refrigerant. If superheat is less than shown, recover

some refrigerant.

Charge Using Approach Method (TXV Systems) –

Outdoor Temperatures 65°F or Above

The following procedure is intended as a general guide

and is for use on expansion valve systems only. For best

results, indoor temperature should 70°F to 80°F. Monitor

system pressures while charging.

1. Record outdoor ambient temperature using a digital

thermometer.

2. Attach high pressure gauge set and operate unit for

several minutes to allow system pressures to stabilize.

3. Compare stabilized pressures with those provided in

Table 8 on page 14. Minor variations in these pres-

sures may be expected due to differences in installa-

tions. Significant differences could mean that the

system is not properly charged or that a problem

exists with some component in the system.

_____ ° Liquid Line Temperature °F

_____ ° Outdoor Ambient Temperature °F

_____ ° Approach Temperature °F

–

=

6. Compare the approach value with those shown in

Table 9 on page 14. If the values to do not agree with

those provided in Table 9, add refrigerant to lower the

approach temperature or recover refrigerant from the

system to increase the approach temperature.

Check Charge Using Normal Operating Pressures

Use Table 8 on page 14 to perform maintenance checks.

Table 8 is not a procedure for charging the system. Minor

variations in these pressures may be due to differences in

installations. Significant deviations could mean that the

Loading...

Loading...