Page 21

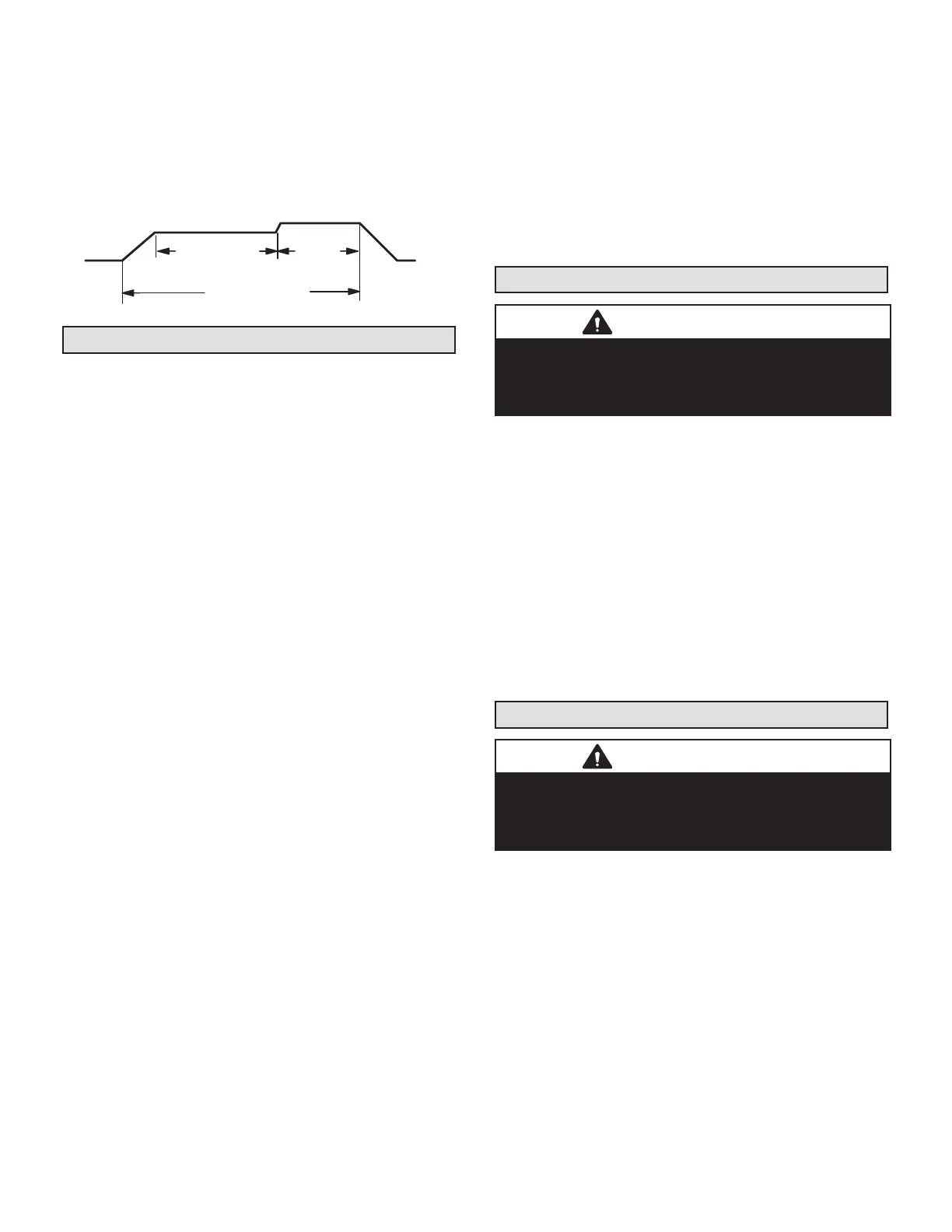

#4 Pins Jumpered

A- Motor ramps up to 82%.

B- Motor then runs at 82% for approximately 7-1/2 min-

utes. If demand has not been satised after 7-1/2 min-

utes,

C- Motor runs at 100% until demand is satised.

D- Once demand is met, motor ramps down to stop.

A

B

OFF

OFF

D

COOLING DEMAND

7 1/2 MIN

82% CFM

100%

CFM

Check-out Procedures

NOTE – Refer to outdoor unit installation instructions for sys-

tem start-up instructions and refrigerant charging instructions.

PRE-START-UP CHECKS

• Is the air handler properly and securely installed?

• If horizontally congured, is the unit sloped up to 5/8

inch toward drain lines?

• Will the unit be accessible for servicing?

• Has an auxiliary pan been provided under the unit with

separate drain for units installed above a nished ceil-

ing or in any installation where condensate overow

could cause damage?

• Have ALL unused drain pan ports been properly

plugged?

• Has the condensate line been properly sized, run,

trapped, pitched, and tested?

• Is the duct system correctly sized, run, sealed, and in-

sulated?

• Have all cabinet openings and wiring been sealed?

• Is the indoor coil factory-installed TXV properly sized for

the outdoor unit being used?

• Have all unused parts and packaging been disposed

of?

• Is the lter clean, in place, and of adequate size?

• Is the wiring neat, correct, and in accordance with the

wiring diagram?

• Is the unit properly grounded and protected (fused)?

• Is the thermostat correctly wired and in a good location?

• Are all access panels in place and secure?

CHECK BLOWER OPERATION

• Set thermostat to FAN ON.

• The indoor blower should come on.

CHECK COOLING OPERATION

• Set thermostat to force a call for cooling (approximately

5ºF lower than the indoor ambient temperature).

• The outdoor unit should come on immediately and the

indoor blower should start between 30 - 60 seconds later.

• Check the air ow from a register to conrm that the

system is moving cooled air.

• Set the thermostat 5ºF higher than the indoor tempera-

ture. The indoor blower and outdoor unit should cycle

o.

CHECK ELECTRIC HEAT (IF USED)

• Set thermostat to call for auxiliary heat (approximate-

ly 5°F above ambient temperature). The indoor blow-

er and auxiliary heat should come on together. Allow a

minimum of 3 minutes for all sequencers to cycle on.

• Set the thermostat so that it does not call for heat. Allow

up to 5 minutes for all sequencers to cycle o.

Maintenance

IMPORTANT

Do not operate system without a lter. A lter is required

to protect the coil, blower, and internal parts from

excessive dirt and dust. The lter is placed in the return

duct by the installer.

• Inspect air lters at least once a month and replace or

clean as required. Dirty lters are the most common

cause of inadequate heating or cooling performance.

• Replace disposable lters. Cleanable lters can be

cleaned by soaking in mild detergent and rinsing with

cold water.

• Install new/clean lters with the arrows on the side point-

ing in the direction of air ow. Do not replace a clean-

able (high velocity) lter with a disposable (low velocity)

lter unless return air system is properly sized for it.

• If water should start coming from the secondary drain

line, a problem exists which should be investigated and

corrected. Contact a qualied service technician.

Repairing or Replacing Cabinet Insulation

IMPORTANT

DAMAGED INSULATION MUST BE REPAIRED OR

REPLACED before the unit is put back into operation.

Insulation loses its insulating value when wet, damaged,

separated or torn.

Matte- or foil-faced insulation is installed in indoor equip-

ment to provide a barrier between outside air conditions

(surrounding ambient temperature and humidity) and the

varying conditions inside the unit. If the insulation barrier

is damaged (wet, ripped, torn or separated from the cabi-

net walls), the surrounding ambient air will aect the inside

surface temperature of the cabinet.

The temperature/humidity dierence between the inside

and outside of the cabinet can cause condensation on the

inside or outside of the cabinet which leads to sheet metal

corrosion and, subsequently, component failure.

Loading...

Loading...