Page 22

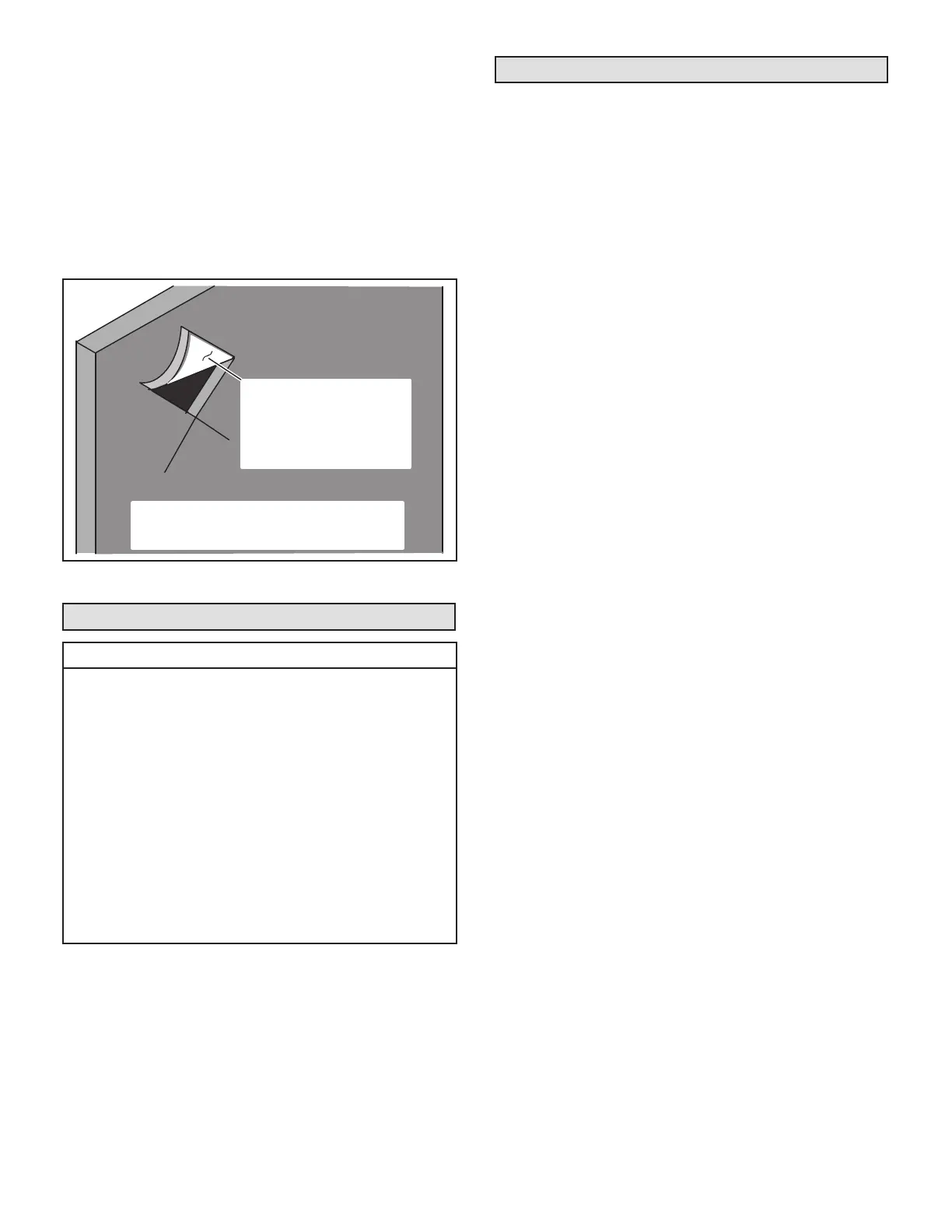

REPAIRING DAMAGED INSULATION

Areas of condensation on the cabinet surface are an indi-

cation that the insulation is in need of repair.

If the insulation in need of repair is otherwise in good con-

dition, the insulation should be cut in an X pattern, peeled

open, glued with an appropriate all-purpose glue and

placed back against the cabinet surface, being careful to

not overly compress the insulation so the insulation can

retain its original thickness. If such repair is not possible,

replace the insulation. If using foil-faced insulation, any

cut, tear, or separations in the insulation surface must be

taped with a similar foil-faced tape.

1. CUT INSULATION IN X PATTERN

2. APPLY GLUE

3. PRESS GLUED TABS AGAINST CABINET

GLUE - Make sure there is

full coverage of glue on the

metal or insulation so there

are no areas where air

pockets may form which

can lead to sweating.

FIGURE 17. Repairing Insulation

Professional Maintenance

NOTICE !

Failure to follow instructions will cause damage to

the unit.

This unit is equipped with an aluminum coil.

Aluminum coils may be damaged by exposure to

solutions with a pH below 5 or above 9. The alumi-

num coil should be cleaned using potable water

at a moderate pressure (less than 50psi). If the

coil cannot be cleaned using water alone, Lennox

recommends use of a coil cleaner with a pH in the

range of 5 to 9. The coil must be rinsed thoroughly

after cleaning.

In coastal areas, the coil should be cleaned with

potable water several times per year to avoid corro-

sive buildup (salt).

Use of Air Handler During Construction

Lennox does not recommend the use of its air handler unit

during any phase of construction. Very low return air tem-

peratures, harmful vapors and operation of the unit with

clogged or misplaced lters will damage the unit.

Air handler units may be used for heating (heat pumps)

or cooling of buildings under construction, if the following

conditions are met:

• A room thermostat must control the air handler. The use

of xed jumpers is not allowed.

• Air lter must be installed in the system and must be

maintained during construction.

• Air lter must be replaced upon construction comple-

tion.

• The air handler evaporator coil, supply fan assembly

and duct system must be thoroughly cleaned following

nal construction clean-up.

• All air handler operating conditions must be veried ac-

cording to these installation instructions.

Loading...

Loading...