Page 7

8 - Refer to instructions provided with outdoor unit for

leak testing, evacuating and charging procedures.

9 - Install access panel.

TABLE 2. Refrigerant Line Sizes

Model

Liquid

Line

Vapor

Line

Line Sets

-018

-024

-030

-036

3/8ʺ

(10mm)

3/4ʺ

(19mm)

L15 line set sizes are

dependant on unit

match-up. See Product

Specications (EHB) for

outdoor unit to determine

correct line set sizes

-042

-048

3/8ʺ

(10mm)

7/8"

(22mm)

-060

3/8ʺ

(10mm)

7/8"

(22mm)

Field fabricated

Installing the Condensate Drain

MAIN DRAIN

Connect the main drain and route downward to drain line

or sump. Do not connect drain to a closed waste system.

See Figure 8 for typical drain trap conguration.

OVERFLOW DRAIN

It is recommended that the overow drain is connected to

an overow drain line for all units. If overow drain is not

connected, it must be plugged with provided cap.

For downow orientation, the overow drain MUST be

connected and routed to a overow drain line. See Fig-

ure 7 for main and overow drain locations based on coil

orientation.

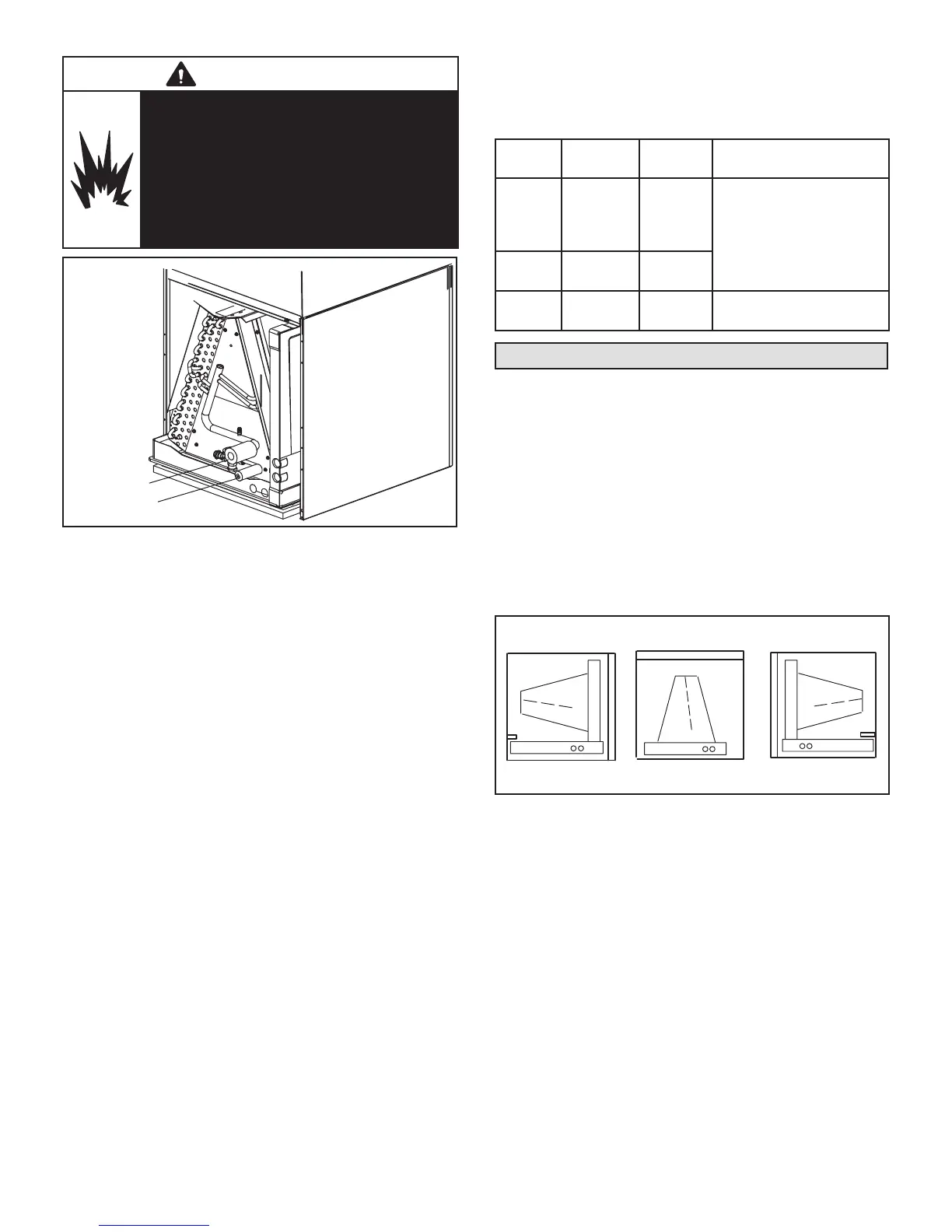

LEFT-HAND AIR

DISCHARGE

MAIN DRAIN ON

RIGHT

OVERFLOW

DRAIN ON LEFT

UP-FLOW OR

DOWN-FLOW

RIGHT-HAND AIR

DISCHARGE

FIGURE 7. Main and Overow Drain Locations

Based on Coil Orientation

BEST PRACTICES

The following best practices are recommended for the

condensate removal process:

• Main and overow drain lines should NOT be smaller

than both drain connections at drain pan.

• Overow drain line should run to an area where home-

owner will notice drainage.

• It is recommended that the overow drain line be vented

and a trap installed. Refer to local codes.

• Condensate drain lines must be congured or provided

with a cleanout to permit the clearing of blockages and

for maintenance without requiring the drain line to be

cut.

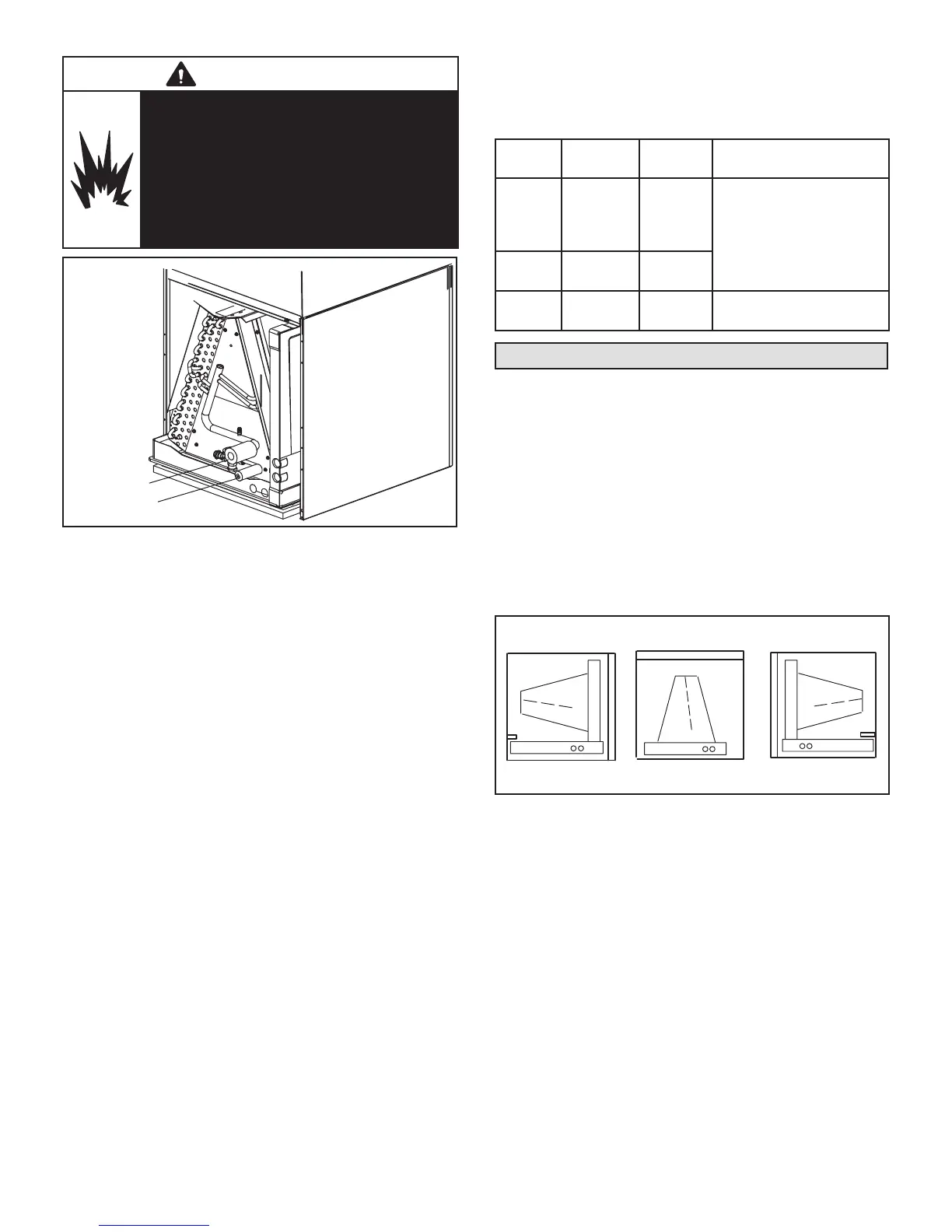

WARNING

Danger of explosion!

Can cause equipment damage, injury, or

death.

When using a high pressure gas such as dry

nitrogen to pressurize a refrigeration or air

conditioning system, use a regulator that can

control the pressure down to 1 or 2 psig (6.9

to 13.8 kPa).

AIR HANDLER UNIT

LIQUID LINE

FIGURE 6. Brazing Connections

NOTE – CBA27UHE series air handlers use nitrogen or

dry air as a holding charge. If there is no pressure when

the rubber plugs are removed, check the coil for leaks

before installing. After installation, pull a vacuum on the

line set and coil before releasing the unit charge into the

system.

NOTE – See outdoor unit instructions on how to ow nitro-

gen through line sets.

1 - Remove access panel.

2 - Remove the refrigerant line caps from the refrigerant

lines.

3 - Use a wet rag to protect TXV sensing bulb (or

remove it) when brazing suction line connections.

4 - Place a wet rag against piping plate and around

the suction line connection. The wet rag must be in

place to guard against damage to the paint.

5 - With the wet rag in place, position a eld provided

elbow tting to the air handler’s suction line and line

set. Start nitrogen ow before brazing.

6 - After the procedure is completed then remove the

wet rag.

7 - Place wet rag against piping plate and around the

liquid line connection. Position liquid line elbow to air

handler’s suction line and to line set. Start nitrogen

ow and begin brazing both connections and after

procedure is completed then remove both wet rags.

Loading...

Loading...