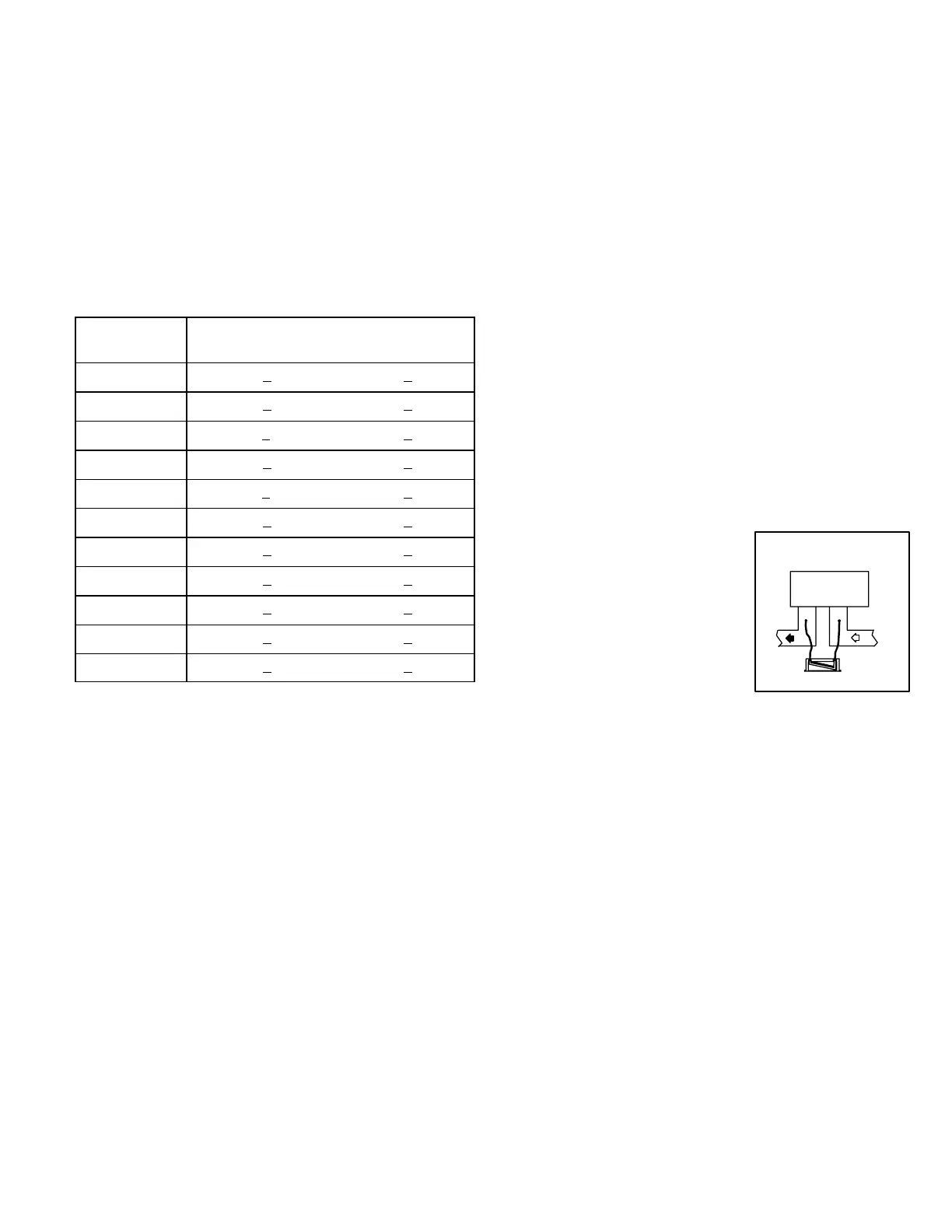

STATIC PRESSURE

TAP LOCATIONS

MANOMETER

UNIT

FIGURE 19

Page 44

APPROACH TEMPERATURE =

LIQUID TEMPERATURE - AMBIENT TEMPERATURE.

If ambient temperature is above 60° F (15° C), read liquid line

temperature. Approach temperature is the difference between

liquid line temperature and ambient temperature.

CAUTION-Use the same thermometer for both temperature

readings.

Approach temperature is shown in table 16. Refrigerant

must be added to lower approach temperature. Remove reĆ

frigerant from system to increase approach temperature.

TABLE 16

APPROACH TEMPERATURE

UNIT

LIQUID TEMP. MINUS

AMBIENT TEMP.

CHP16-024 7°F + 1 (3.9°C + 0.5)

CHP16-030 9°F + 1 (5.0°C + 0.5)

CHP16-036 11°F + 1 (6.0°C + 0.5)

CHP16-048 9°F + 1 (5.0°C + 0.5)

CHP16-060 11°F + 1 (6.0°C + 0.5)

CHP20-024 7°F + 1 (3.9°C + 0.5)

CHP20-030 7°F + 1 (3.9°C + 0.5)

CHP20-036 10°F + 1 (5.6°C + 0.5)

CHP20-042 6°F + 1 (3.3°C + 0.5)

CHP20-048 7°F + 1 (3.9°C + 0.5)

CHP20-060 12°F + 1 (6.7°C + 0.5)

If ambient temperature is less than 60° F (16° C), air flow

must be restricted to achieve pressures in the 200-250 psig

range. These higher pressures are necessary for checking

charge. To accomplish this, block the outdoor coil from top to

bottom evenly from both ends.

VIII-HEATING SYSTEM SERVICE CHECKS

A-Heating - Heat Pump

1- Set thermostat switch in Heat" position and blower

switch in On" or Auto" position. Set heating adjustment

lever above room temperature. Close unit disconnect

switch.

2- Compressor will cycle on demand from room thermoĆ

stat and outdoor coil fan will cycle with compressor.

Blower will operate according to position of blower

switch on thermostat.

3- A defrost control is used to prevent excessive outdoor

coil icing. As a defrost cycle is initiated, the reversing

valve switches, inducing heat to outdoor coil. Outdoor

fan stops during this process.

B-Heating - Optional Electric Heat

1- When heat requirements exceed heat pump capacity,

the thermostat automatically activates the optional

electric heat through W2.

IX-INDOORā BLOWER

OPERATION / ADJUSTMENT

Unit is equipped with direct drive, multi-speed indoor

blower. See unit wiring diagram for factory setting. Table

17 gives minimum blower speeds for CHP16 & 20 units

equipped with optional electric heat.

A-Blower Operation

1- Blower operation is manually set at the thermostat

subbase fan switch. When fan switch is in On" posiĆ

tion, blower operates continuously.

2- When fan switch is in Auto" position, blower will

cycle with demand. Blowers and entire unit will be off

when system switch is in Off" position.

To Measure Discharge Static Pressure:

a-Measure tap locations (figure 19).

b-Punch a 1/4" diameter hole. Insert manometer hose

flush with the inside edge of

hole or insulation. Seal

around hole with PermaĆ

gum. Connect the zero end

of the manometer to the disĆ

charge (supply) side of the

system. Connect other end

of manometer to the return

duct as above.

c-With only the blower motor running, observe the maĆ

nometer reading.

d-Seal around the hole when check is complete.

3- The CFM can be adjusted by changing the motor speed

taps. Follow the blower speed change instructions beĆ

low.

B-Blower Operation Adjustment

208-230 Volt Units - Blower speed selection is accomĆ

plished by changing the taps at the harness connector at

the blower motor. See figure 20 and unit diagram.

460-575 Volt Units-Blower speed selection is accomĆ

plished by changing the J38 blower speed jack in the return

air section. See unit wiring diagram.

IMPORTANTĊTo prevent motor burnout, never connect

more than one motor lead to any one connection. Black

and blue motor taps must be connected together when

operating on low or medium speeds. Tape unused motor

leads separately.

Loading...

Loading...