Page 45

C-Minimum Blower Speed

(With Electric Heat)

Refer to ECH16 installation instructions for minimum alĆ

lowable blower speed when electric heat is used.

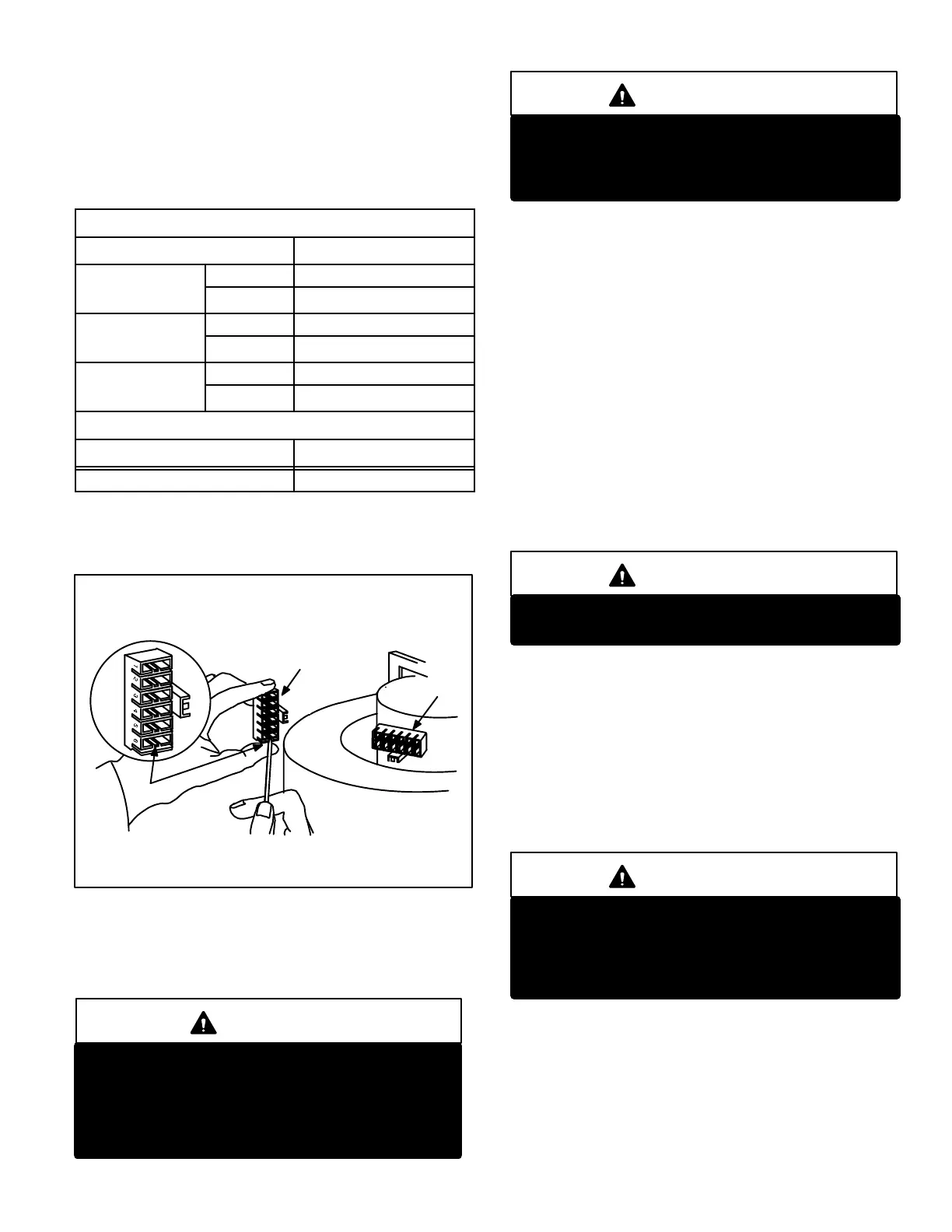

TABLE 17

ELECTRIC HEAT ONLY (EMERGENCY HEAT)

CHP16 & 20 UNIT Min. Blower Speed

208/240V Med. - High

-

,

,

460/575V Medium

208/240V Med. - High

-

460/575V Medium

208/240V High

-

,

460/575V Medium

OPTIONAL ELECTRIC HEAT

UNIT Min. Blower Speed

ALL UNITS High

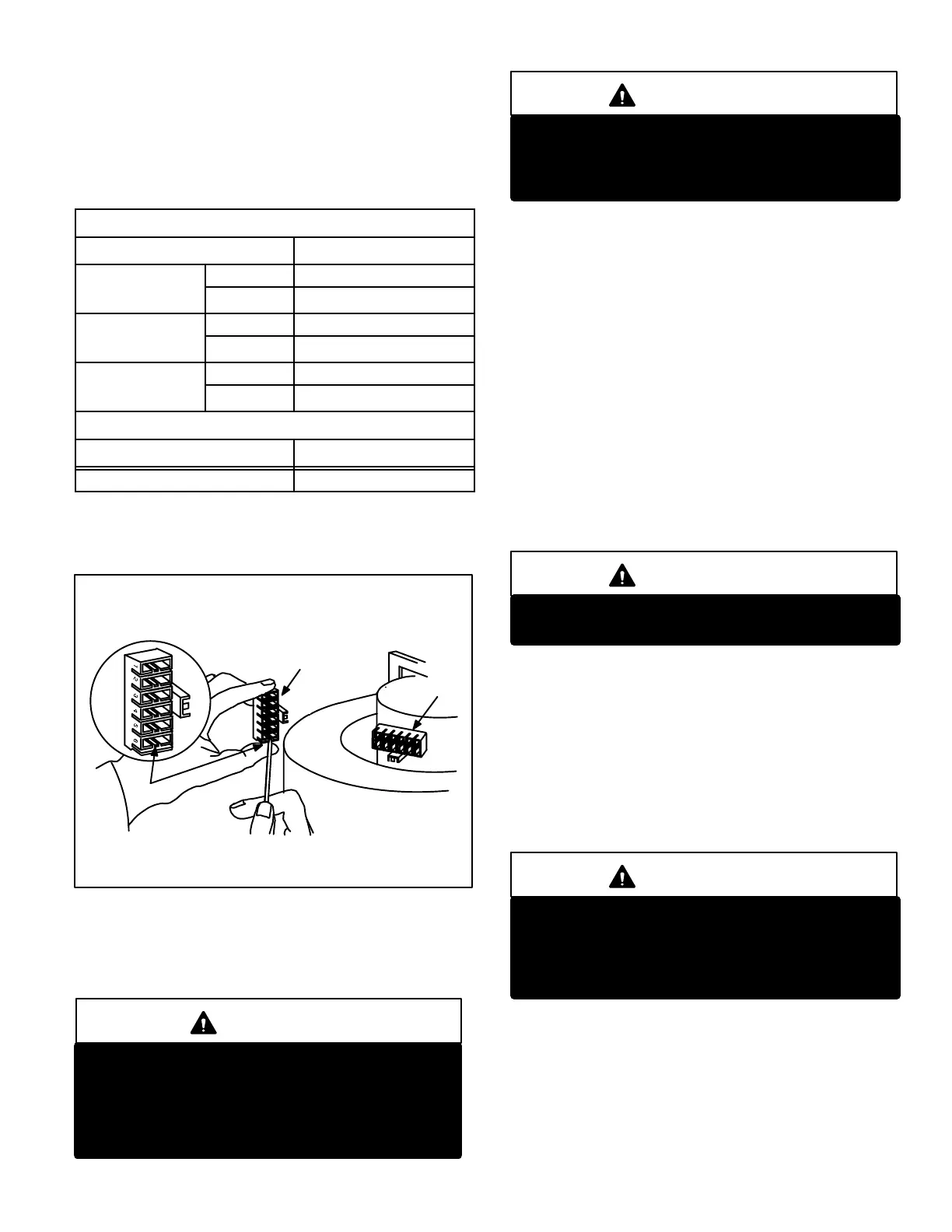

BLOWER SPEED TAP SELECTION

208-230V UNITS

HARNESS CONNECTOR

DEPRESS TAB TO RELEASE WIRE

CONNECTOR. SELECT CONNECTOR

LOCATION FOR NEW SPEED. INSERT

WIRE UNTIL IT CLICKS.

RELEASE

FIGURE 20

X-MAINTENANCE

e

Potential for personal injury.

Disconnect power to unit before performing any

maintenance or service operation. Avoid contact

with sharp metallic edges.

Can cause prsonal injury or death.

CAUTION

A-Lubrication

IMPORTANT

Always relubricate motors according to manufacĆ

turer's lubrication instructions provided on each

motor. If no instructions are provided, use the folĆ

lowing as a guide:

1 - Supply Air Motor Bearings - Bearings are prelubriĆ

cated; no further lubrication is required for 10 years

of normal operation. Thereafter, oil at oiling ports

with a SAE 10W non detergent motor oil or suitable

equivalent.

3 - Condenser Fan Motor Bearings - Bearings are preĆ

lubricated. For extended bearing life, lubricate each

bearing through the oiling ports provided with a few

drops of a good grade electric motor oil or SAE10 or

SAE20 non-detergent motor oil every two years.

B-Filters

Filters should be checked monthly (or more frequently in seĆ

vere use) and cleaned or replaced regularly. Take note of

the "AIR FLOW DIRECTION" marking on the filter frame

when re-installing.

IMPORTANT

FIlters must be U.L.C certified or equivalent for

use in Canada.

1 - Clean coil, if necessary.

2 - Check connecting lines and coil for oil leaks.

3 - Check condensate drain pan and line, if necessary.

C-Condenser Coil

1 - Clean and inspect condenser coil. (May be flushed with

a water hose.)

2 - Visually inspect connecting lines and coils for evidence

of oil leaks.

IMPORTANT

If owner complains of insufficient cooling, unit

should be gauged and refrigerant charge

checked. Refer to gauge manifold attachment,

checking charge and charging sections in this inĆ

structions.

D-Electrical

1 - Check all wiring for loose connections.

2 - Check for correct voltage at unit (unit operating).

3 - Check amp-draw on both condenser fan motor and

blower motor.

Fan Motor Rating Plate ____ Actual ________

Indoor Blower Motor Rating Plate____ Actual____

Loading...

Loading...