Do you have a question about the Lennox CLIMATIC series and is the answer not in the manual?

| Connectivity | Wi-Fi |

|---|---|

| Compatibility | Lennox HVAC systems |

| User Interface | Touchscreen |

| Remote Access | Yes, via app |

| Energy Management | Energy-saving modes |

| Display | Color |

| Programmability | 7-day programmable |

Microprocessor-based control for LENNOX rooftop range and its program compatibility.

Critical safety warnings and explanation of the DS menu for parameter access.

Defines clock zones and operating modes for weekly unit scheduling.

Allows unit startup based on temperature and advanced scheduling options.

Maintains room temperature via set points, dead zones, and thresholds.

Adjusts set points based on outside temperature for efficiency.

Manages set points from external DC or BMS sources.

Controls heating/cooling staging based on temperature gap and controller settings.

Manages blowing air temperature in cooling and dead zones.

Controls blowing air temperature independently of room temperature.

Manages relative humidity for comfort and economic usage.

Manages the main supply fan with variable speed for efficiency and control.

Manual or Auto airflow control based on speed or m³/h.

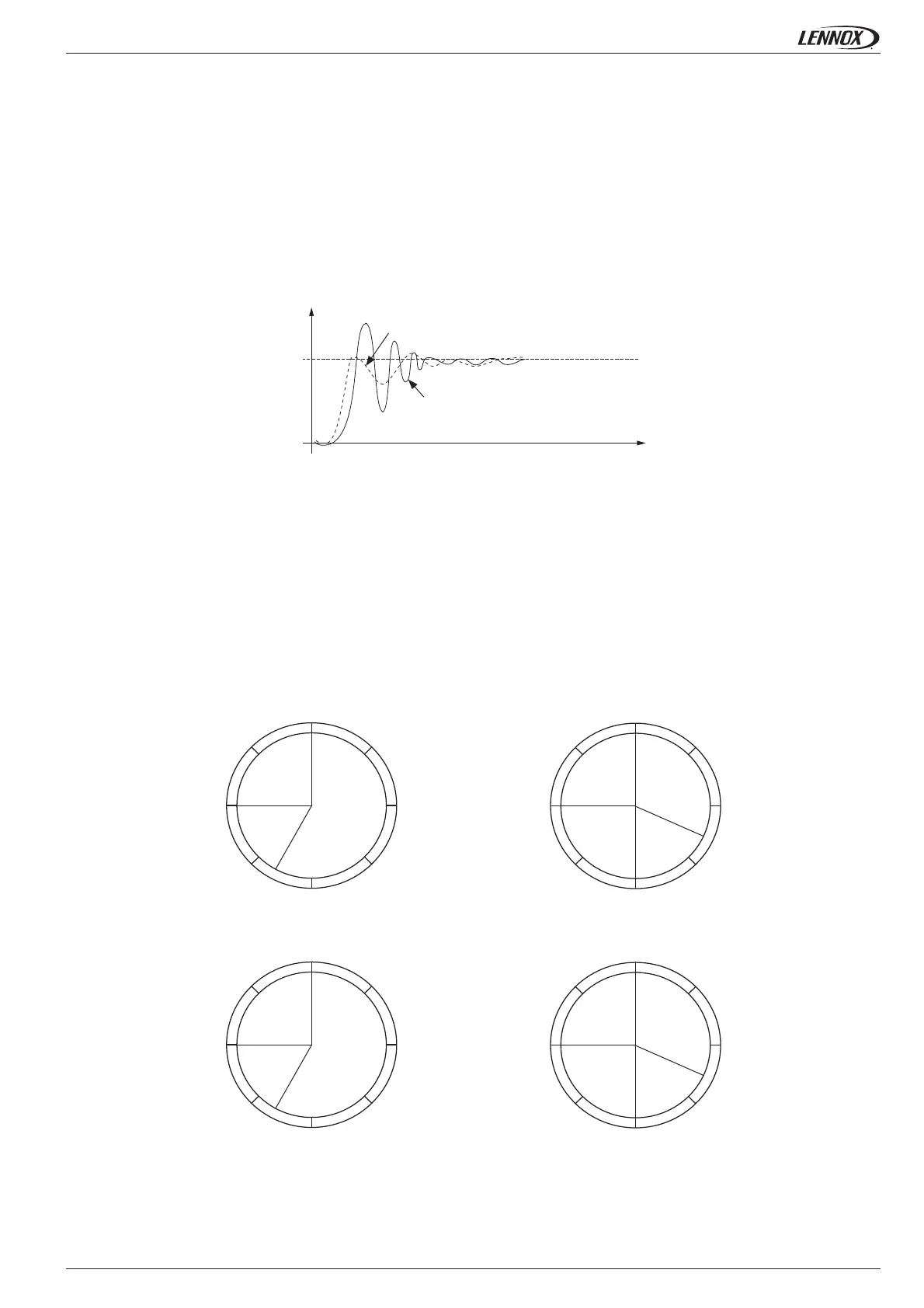

Manages compressors based on demand and calculates required number.

Disables compressors based on outside air temperature thresholds.

Maintains high pressure stable and manages fan speed using acoustic modes.

Offers 'Auto', 'Quiet', 'Auto Quiet' modes to manage condenser fan speed.

Manages defrost to avoid ice on evaporator coil in heating mode.

Ensures minimum fresh air and free-cooling/heating for reduced consumption.

Optimizes air quality and activates free cooling/heating.

Controls free cooling based on outdoor temp, humidity, and contacts.

Manages exhaust fans (step or continuous) based on fresh air opening.

Recovers energy from exhaust air using various heat recovery types.

Manages supplementary heating types like gas, electric, and hot water.

Controls electrical heaters and hot water circulator functions.

Provides I/O on boards for remote control customization.

Configures analog and digital inputs for various sensors and signals.

Settings for configuring custom I/O functionalities for relays and digital inputs.

Configures digital outputs for alarms, modes, and schedules.

Settings for configuring custom I/O functionalities for analog inputs.

Connects up to 8 units for system operation with various management modes.

Plug and play terminal for maintenance/service, accessing advanced functionalities.

Navigates DS menus and modifies settings, including schedule-specific options.

Connects to BMS for integrated building management.

Configures Modbus slave protocol and ensures communication monitoring.

Lists alarm codes and their descriptions for various system failures and warnings.

Alarm for low differential pressure indicating airflow obstruction.

Alarms for filter problems and electrical heater overheating.

Alarms for hot water frosting risk and gas burner failures.

Alarms for temperature probes out of range and high air quality.

Alarms for humidifier failure, pump failure, and humidity out of range.

Alarms for recovery motor, wheel, or filter failures.

Alarms for CLIMATIC board link failure and real-time clock board failure.

Alarms for expansion board or inverter link disconnections.

Alarms for incorrect temperature or pressure sensor readings.

Alarms for fan motor failure and fire/smoke detection.

Alarms for fan inverter failures and condenser fan electrical issues.

Alarms for refrigerant leaks and compressor electrical failures.

Alarms for reversing valve blockage and low operating pressure.

Alarms for evaporator frosting risk and superheat temperature issues.

Alarms for condenser subcooling and operating pressure anomalies.

Alarms for condenser temperature being too low or too high.

Details BMS parameters for Modbus, BACnet, Trend, Carel, and Lonworks protocols.

List of Modbus addresses for control parameters, states, and energy values.

List of Modbus addresses for unit states and blower parameters.

List of Modbus addresses for alarms and states related to Circuit 2.

List of Modbus addresses for alarms and states related to Circuit 1.

List of Modbus addresses for Circuit 1 temperature related alarms.

List of Modbus addresses for remote controls and unit states.

List of Lonworks parameters for watchdog and alarm codes.

List of Lonworks parameters for temperature and humidity settings.

List of Lonworks parameters for compressor and heater states.

List of Lonworks error bits for Circuit 2 alarms.

List of Lonworks error bits for Circuit 1 alarms.

List of Lonworks error bits and digital states.

List of Lonworks digital states for various components.

List of Lonworks digital states for various components.

Details digital input and output assignments for BM and BE boards.

Details analog I/O and serial port configurations for CLIMATIC 60.

Lists eCLIMATIC input assignments for BM boards.

Lists eCLIMATIC input assignments for BE boards.

Details eCLIMATIC output assignments for BM boards.

Details eCLIMATIC output assignments for BE boards.

Lists eCLIMATIC serial port configurations for BMS cards.

Covers alarm history, unit settings, clock, scheduling zones, and modes.

Details anticipation, relay states, and dry contact settings.

Covers signal values, temperature/humidity readings, set points, and control.

Covers dehumidification, humidification, safety, and compressor configurations.

Covers condenser, cooling, heating modes, and related temperature thresholds.

Covers loop, expansion valve, heater, and humidifier configurations.

Covers pump, economizer, free cooling/heating, and air quality settings.

Covers exhaust, fan control, compressor activation, and leak detection settings.

Covers compressor activation, temperature thresholds, integral times, and condenser settings.

Covers temperature/humidity offsets, thresholds, and integral times.

Covers defrost parameters, PID control, expansion valve, and heater settings.

Covers hot water, economizer, exhaust fan, and air quality settings.

Covers free cooling, free heating, and recovery settings.

Covers power meter configuration, RS485 bus, and current thresholds.