Page 50

VI-MAINTENANCE

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly could

result in dangerous operation, serious injury, death

or property damage.

Improper servicing could result in dangerous

operation, serious injury, death, or property damage.

Before servicing, disconnect all electrical power to

furnace.

When servicing controls, label all wires prior

to disconnecting. Take care to reconnect wires

correctly. Verify proper operation after servicing.

At the beginning of each heating season, system should

be checked as follows by a qualied service technician:

Blower

Check the blower wheel for debris and clean if necessary.

The blower motors are prelubricated for extended bearing

life. No further lubrication is needed.

WARNING

The blower access panel must be securely in place

when the blower and burners are operating. Gas

fumes, which could contain carbon monoxide, can

be drawn into living space resulting in personal

injury or death.

Filters

All air lters are installed external to the unit. Filters should

be inspected monthly. Clean or replace the lters when

necessary to ensure proper furnace operation. Table 27

lists recommended lter sizes.

IMPORTANT

If a higheciency lter is being installed as part of

this system to ensure better indoor air quality, the

lter must be properly sized. Higheciency lters

have a higher static pressure drop than

standardeciency glass/foam lters. If the pressure

drop is too great, system capacity and performance

may be reduced. The pressure drop may also cause

the limit to trip more frequently during the winter and

the indoor coil to freeze in the summer, resulting in

an increase in the number of service calls.

Before using any lter with this system, check the

specications provided by the lter manufacturer

against the data given in the appropriate Lennox

Product Specications bulletin. Additional

information is provided in Service and Application

Note ACC002 (August 2000).

TABLE 26

Cabinet Width Filter Size

17-1/2”

16 x 25 x 1(1)

21”

Exhaust and air intake pipes

Check the exhaust and air intake pipes and all connec-

tions for tightness and to make sure there is no blockage.

NOTE - After any heavy snow, ice or frozen fog event the

furnace vent pipes may become restricted. Always check

the vent system and remove any snow or ice that may be

obstructing the plastic intake or exhaust pipes.

Electrical

CAUTION

Failure to use properly sized wiring and circuit

breaker may result in property damage. Size wiring

and circuit breaker(s) per Product Specications

bulletin (EHB) and unit rating plate.

1 - Check all wiring for loose connections.

2 - Check for the correct voltage at the furnace (furnace

operating).

3 - Check amp-draw on the blower motor.

Motor Nameplate__________Actual__________

Winterizing and Condensate Trap Care

1 - 1 - Turn o power to the furnace.

2 - Have a shallow pan ready to empty condensate

water.

3 - Remove the clean out cap from the condensate trap

and empty water. Inspect the trap then reinstall the

clean out cap.

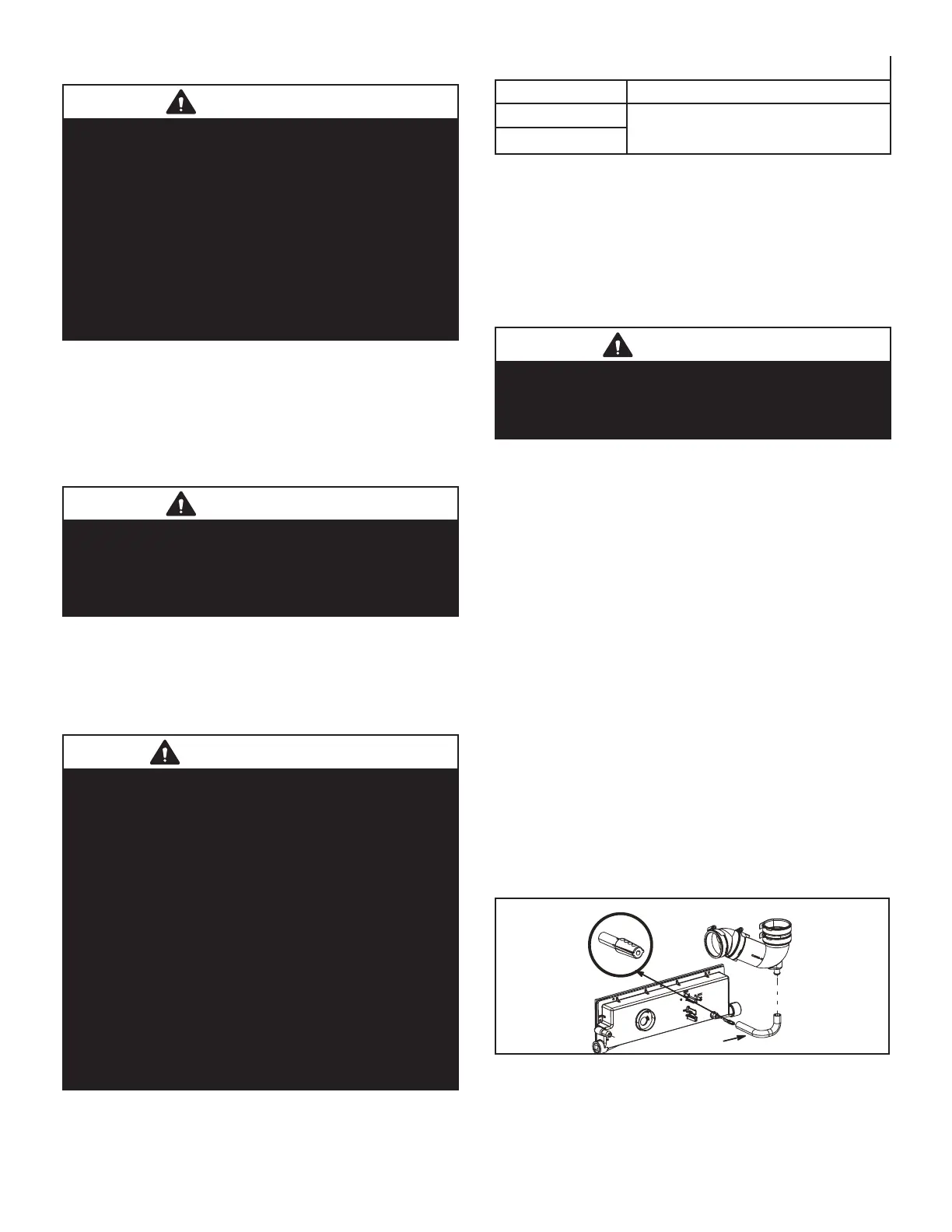

Condensate Hose Screens (Figure 57)

Check the condensate hose screens for blockage and

clean if necessary.

1 - Turn o power to the unit.

2 - Remove hoses from cold end header box. Twist

and pull screens to remove.

3 - Inspect screens and rinse with tap water if needed.

4 - Reinstall screens, reconnect hoses and turn on

power to unit.

Hose

FIGURE 57

Loading...

Loading...