Page 7

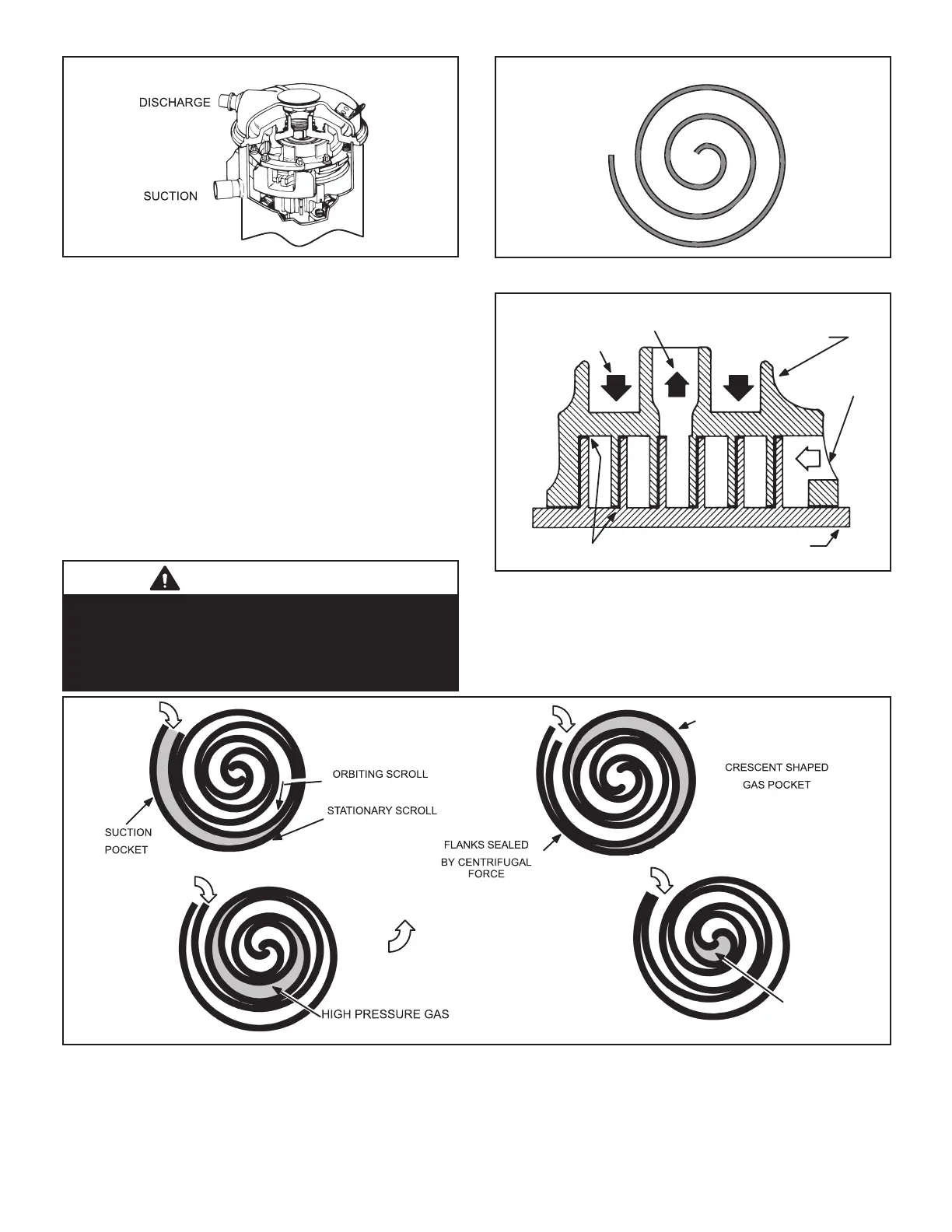

SCROLL COMPRESSOR

FIGURE 4

The scroll compressor design is simple, ecient and re-

quires few moving parts. A cutaway diagram of the scroll

compressor is shown in gure 4. The scrolls are located

in the top of the compressor can and the motor is located

just below. The oil level is immediately below the motor.

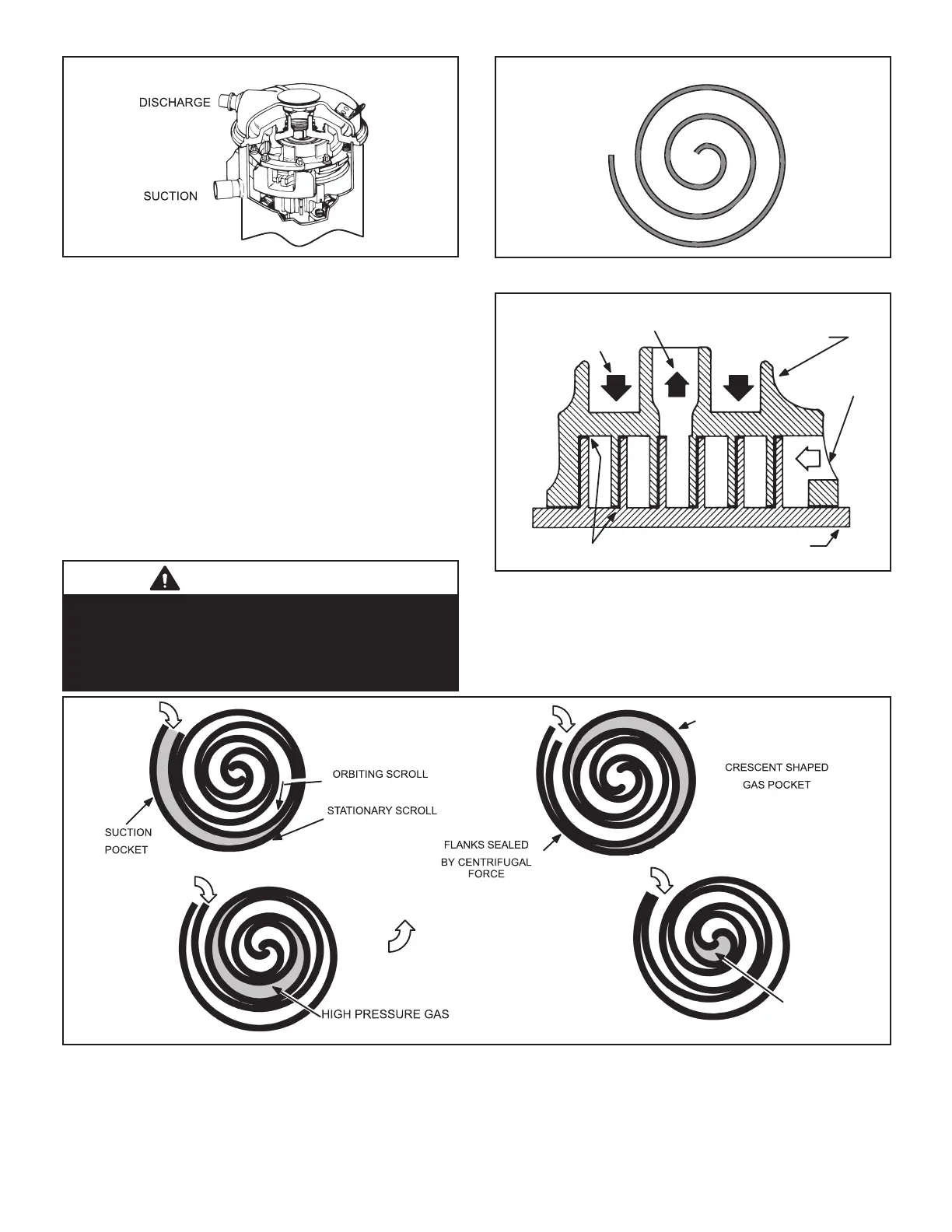

The scroll is a simple compression concept centered

around the unique spiral shape of the scroll and its in-

herent properties. Figure 5 shows the basic scroll form.

Two identical scrolls are mated together forming concen-

tric spiral shapes (gure 6). One scroll remains stationary,

while the other is allowed to ”orbit” (gure 7). Note that the

orbiting scroll does not rotate or turn but merely orbits the

stationary scroll.

NOTE – During operation, the head of a scroll compressor

may be hot since it is in constant contact with discharge gas.

IMPORTANT

Three-phase scroll compressor noise will be signicantly

higher if phasing is incorrect. Compressor will operate

in reverse, so unit will not provide cooling. If phasing is

incorrect, disconnect power to unit and reverse any two

power leads (L1 and L3 preferred) to unit.

SCROLL FORM

FIGURE 5

STATIONARY SCROLL

ORBITING SCROLL

DISCHARGE

SUCTION

CROSS-SECTION OF SCROLLS

TIPS SEALED BY

DISCHARGE

PRESSURE

FIGURE 6

1

2

3

4

SUCTION

SUCTION

SUCTION

DISCHARGE

POCKET

SUCTION

INTERMEDIATE PRESSURE

GAS

MOVEMENT OF ORBIT

FIGURE 7

Loading...

Loading...