Page 29

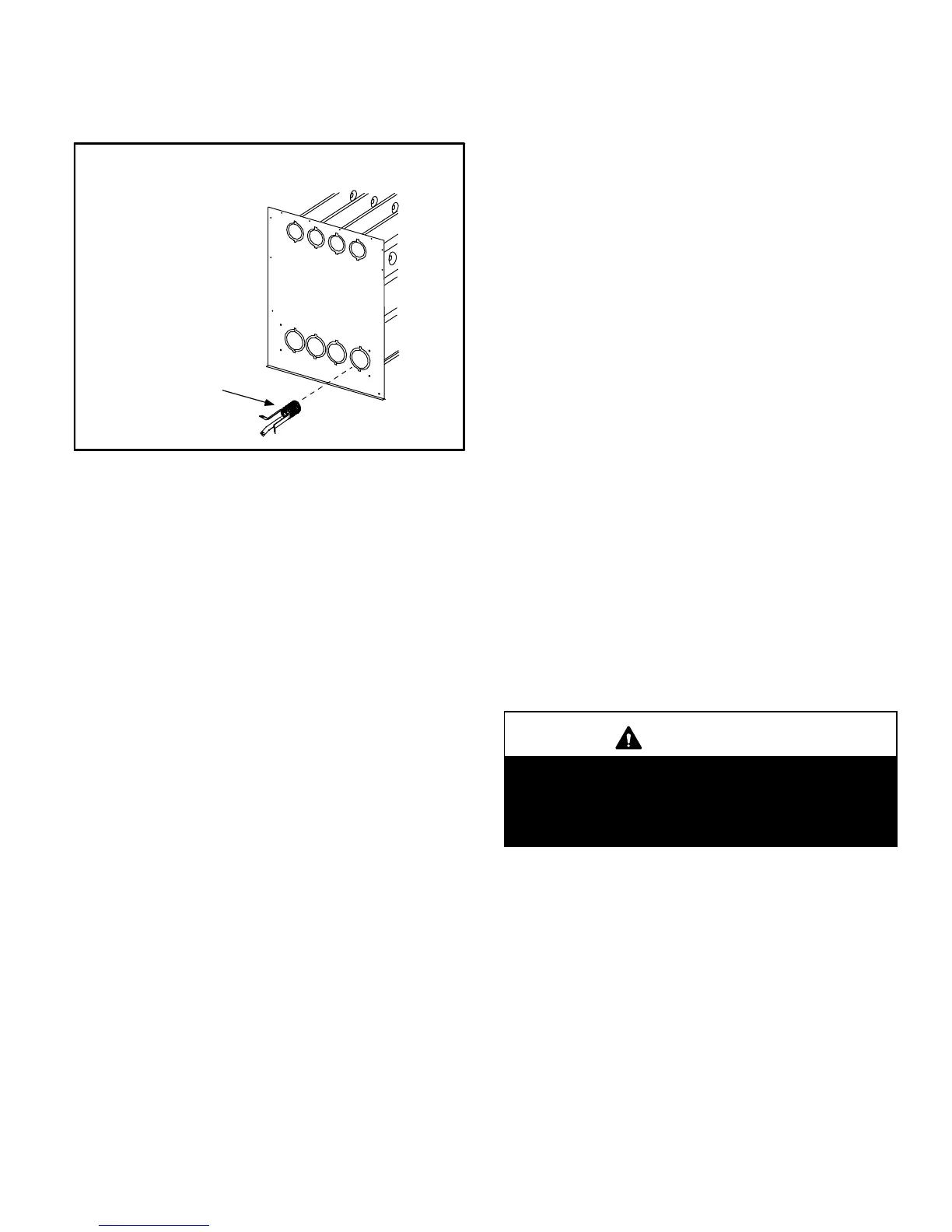

8 −Disconnect gas supply piping. Remove four screws se-

curing the burner manifold assembly to the vestibule

panel and remove the assembly from the unit.

NO

x

INSERTS

(X models only)

FIGURE 28

NO

x

INSERT

9 −NOx units only − Remove the three screws that attach

the NO

x

insert to the corbel at the entrance to each

heat exchanger section. Carefully remove the NO

x

in-

sert from each section. See figure 28.

10 −Insert the brush end of cable snake into the top of one

of the heat exchanger openings. Do not force the

cable into the heat exchanger. Insert the cable and

operate the drill on slow speed. Move the cable in and

out of the heat exchanger section three or four times or

until sufficient cleaning is accomplished. Reverse drill

and slowly work the cable out of opening.

11 −Repeat procedure for each heat exchanger section.

12 −After each of the top heat exchanger sections has

been cleaned, insert the brush end of the cable snake

into the bottom openings of each of the heat exchanger

sections and clean as described in step 8.

13 −Remove the cable from the heat exchanger. Use a

vacuum cleaner to remove debris knocked loose dur-

ing cleaning.

14 −Attach the exhaust end (positive pressure) of the vacu-

um cleaner to the top of the heat exchanger section.

Any loose debris will be forced to the bottom of the heat

exchanger section. Vacuum debris from bottom open-

ings.

15 −Replace collector box and combustion air inducer.

Check gaskets for damage. Damaged gaskets must

be replaced to avoid heat exchanger leaks. Replace all

screws to the collector box and combustion air inducer.

Failure to replace all screws may cause leaks.

16 −To clean the burner, run a vacuum cleaner with a soft

brush attachment over the face of burners. Inspect in-

side the burners and crossovers for any blockage.

Clean the inside of the burner if necessary.

17 −Label and disconnect the pressure switch wires.

18 −Remove the four screws that secure the combustion

air inducer. Carefully remove the combustion air induc-

er to avoid damaging the blower gasket. If the gasket is

damaged, it must be replaced to prevent leakage. See

figure 27.

19 −NO

x

Units − Reattach the NO

x

inserts to the corbels at

the entrance to each heat exchanger opening. See fig-

ure 28.

20 −Reinstall the burner/manifold assembly on the vesti-

bule panel.

21 −Reconnect wires to pressure switch, roll−out switches,

gas valve and combustion air inducer. Refer to unit wir-

ing diagram.

22 −Use screws to resecure the junction box to the cabinet.

23 −Apply RTV/high temperature silicone sealant between

the internal flue pipe and the combustion air inducer.

24 −Use one screw to resecure the internal flue pipe to the

combustion air inducer.

25 −Use three screws to resecure the vent pipe to the flue

collar. See figure 10.

26 −Reconnect the gas supply piping.

27 −Turn on power and gas supply to the unit.

28 −Set thermostat and check for proper operation.

29 −Check all piping connections, factory and field, for gas

leaks. Use a leak detecting solution or other preferred

means.

CAUTION

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly af-

ter leak test has been completed. Do not use

matches, candles, flame or other sources of ignition

to check for gas leaks.

30 −If a leak is detected, shut gas and electricity off and re-

pair leak.

31 −Repeat steps 35 and 36 until no leaks are detected.

32 −Replace front access panels.

Loading...

Loading...