Page 5

LGH/LCH036, 048, 060, 072, 074

Shipping and Packing List

Package 1 of 1 contains:

1- Assembled unit

Check unit for shipping damage. Receiving party should

contact last carrier immediately if shipping damage is found.

General

These instructions are intended as a general guide

and do not supersede local codes in any way.

Authorities having jurisdiction should be consulted

before installation.

The LGH units are available in several heating inputs. The

LCH cooling packaged rooftop unit is the same basic

design as the LGH unit except for the heating section.

Optional electric heat is available for LCH units. LGH and

LCH units have identical refrigerant circuits with

respective 3, 4, 5, and 6 ton cooling capacities.

Standard and high efficiency units are equipped with a

lightweight, all-aluminum condenser coil; optional fin/tube

condenser coils are available. Ultra high efficiency units are

equipped with fin/tube condenser coils.

Units are equipped with the compressors shown in table 1.

TABLE 1

COMPRESSORS

Unit T'Stat Compressor

072H 2-Stage Single-Speed

036S, 048S, 060S,

036H, 048H, 060H, 074H

2- or 3-Stage 2-Step Capacity

036U, 048U, 060U, 074U 2- or 3-Stage

Variable Speed,

2-Step Capacity

036U, 048U, 060U, 074U Zone Sensor Variable Speed

In addition to standard heating and cooling, hot gas

reheat units provide a dehumidifying mode of operation.

Refer to Reheat Operation section.

High efficiency units may be equipped with a Unit

Controller that is factory-configured for “Advanced Air

Flow Control”. This option allows the installer to enter both

the design-specified supply air CFM and outdoor air

CFM. See the Advanced Air Flow Control Start-Up

section. These units are equipped with a variable speed,

direct drive blower and an economizer.

Availability of units and options varies by brand.

Requirements

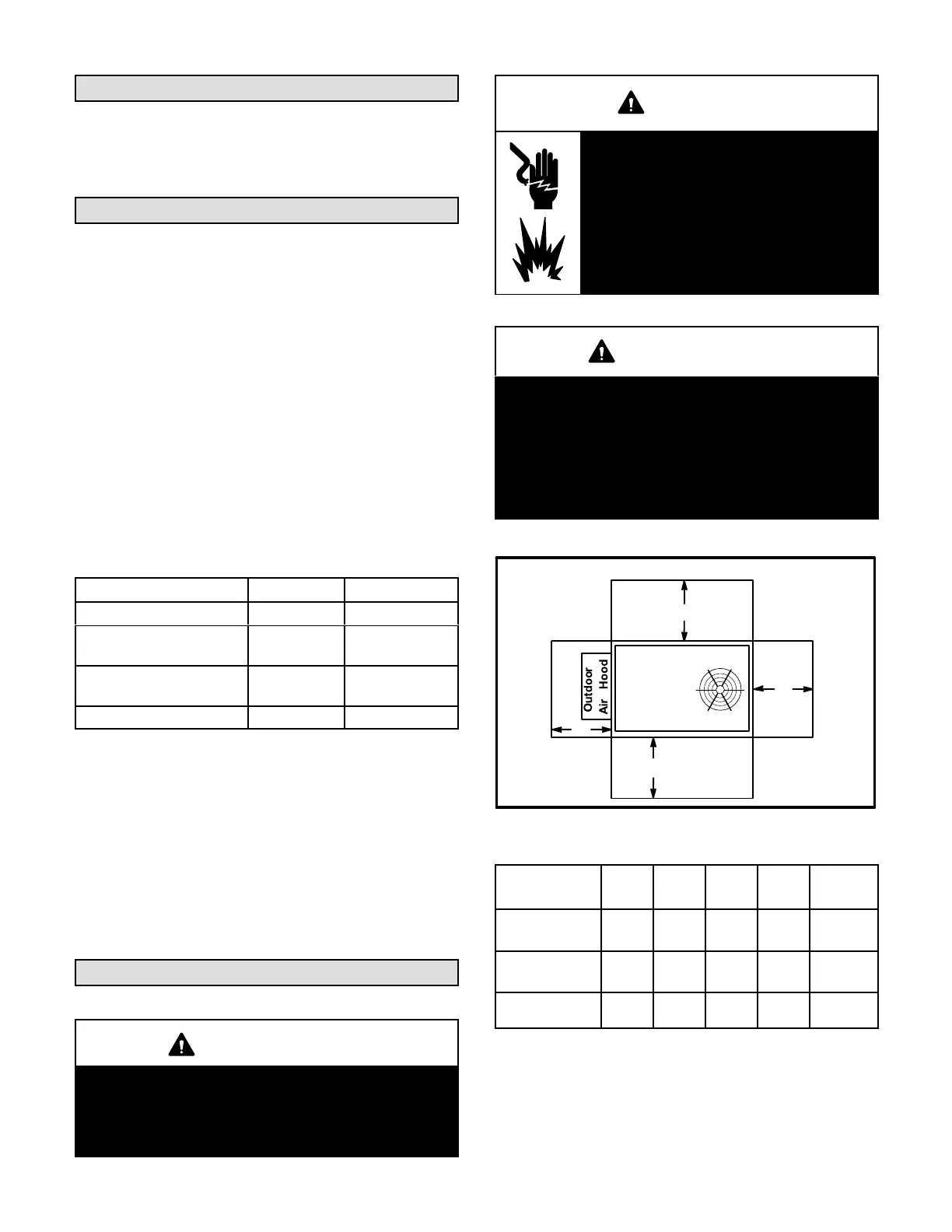

See figure 1 for unit clearances.

IMPORTANT

The Clean Air Act of 1990 bans the intentional vent

ing of refrigerant (CFC's and HCFC's) as of July 1,

1992. Approved methods of recovery, recycling or

reclaiming must be followed. Fines and/or incar

ceration may be levied for non-compliance.

WARNING

Electric shock hazard and danger of

explosion. Can cause injury, death or

product or property damage. Turn off

gas and electrical power to unit before

performing any maintenance or

servicing operations on the unit. Follow

lighting instructions attached to unit

when putting unit back into operation

and after service or maintenance.

NOTICE

Roof Damage!

This system contains both refrigerant and oil.

Some rubber roofing material may absorb oil,

causing the rubber to swell. Bubbles in the rubber

roofing material can cause leaks. Protect the roof

surface to avoid exposure to refrigerant and oil

during service and installation. Failure to follow

this notice could result in damage to roof surface.

UNIT CLEARANCES

C

D

B

A

FIGURE 1

1

Unit

Clearance

A

in.(mm)

B

in.(mm)

C

in.(mm)

D

in.(mm)

Top

Clearance

Service

Clearance

48

(1219)

36

(914)

36

(914)

36

(914)

Unob

structed

Clearance to

Combustibles

36

(914)

1

(25)

1

(25)

1

(25)

Unob

structed

Minimum Opera

tion Clearance

36

(914)

36

(914)

36

(914)

36

(914)

Unob

structed

Note - Entire perimeter of unit base requires support when elevated above

mounting surface.

1

Service Clearance - Required for removal of serviceable parts.

Clearance to Combustibles - Required clearance to combustible material

(gas units).

Minimum Operation Clearance - Required clearance for proper unit operation.

Loading...

Loading...