Page 70

LGH/LCH036, 048, 060, 072, 074

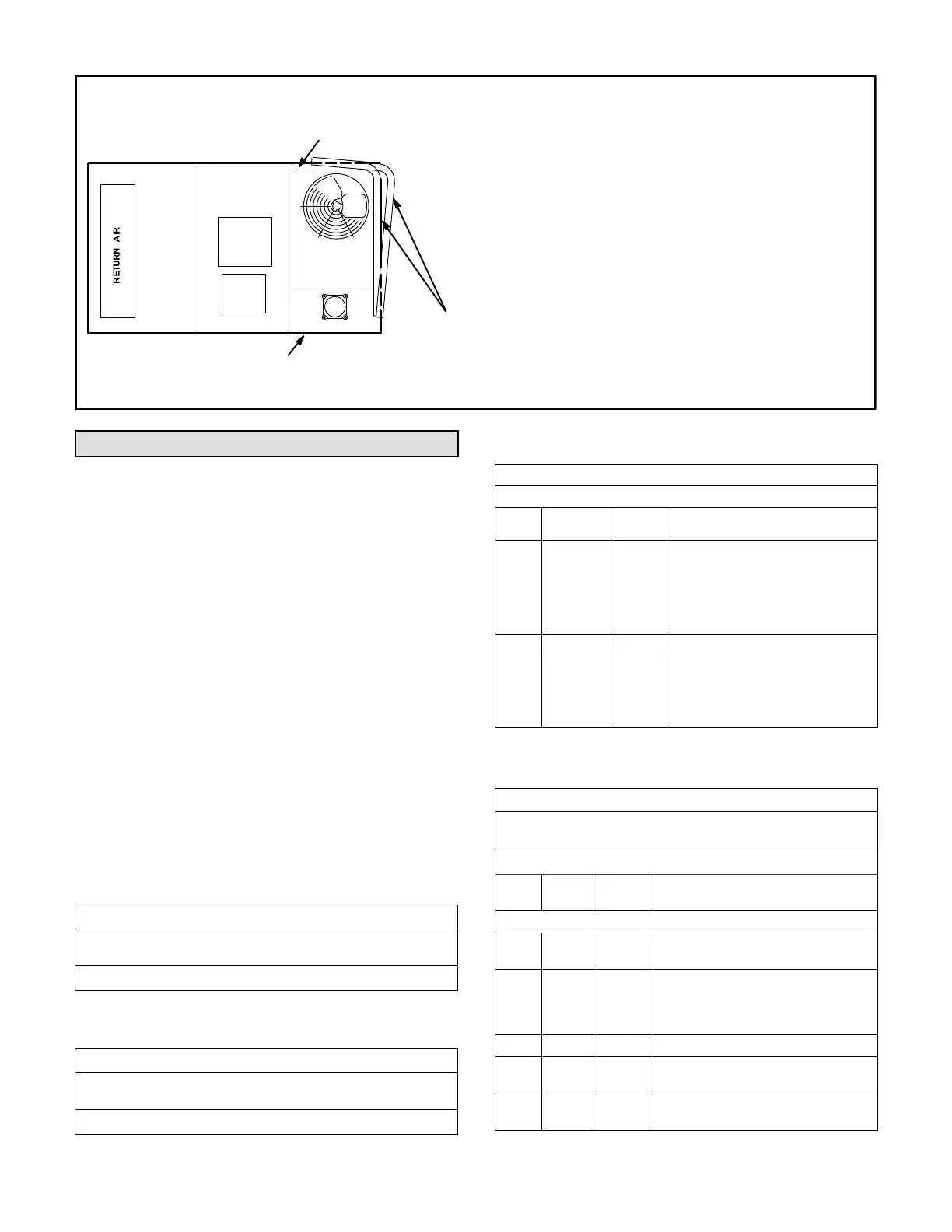

TOP VIEW

CONDENSER

COILS

BLOWER

CONDENSER ACCESS PANEL

FIGURE 37

ENDPLATE IS SECURED

TO MULLION

1- Remove unit top panel and condenser section access

panel.

2- Remove screws securing coil end plate to mullion.

3- Remove wire ties connecting coils slabs and separate

slabs 3-4” (76-102mm).

4- Clean coils with detergent or commercial coil cleaner.

5- Rinse thoroughly with water and reassemble

. Use

field-provided wire ties to connect coil slabs.

CLEAN CONDENSER COIL - UNITS WITH FIN/TUBE COILS

SUPPLY

AIR

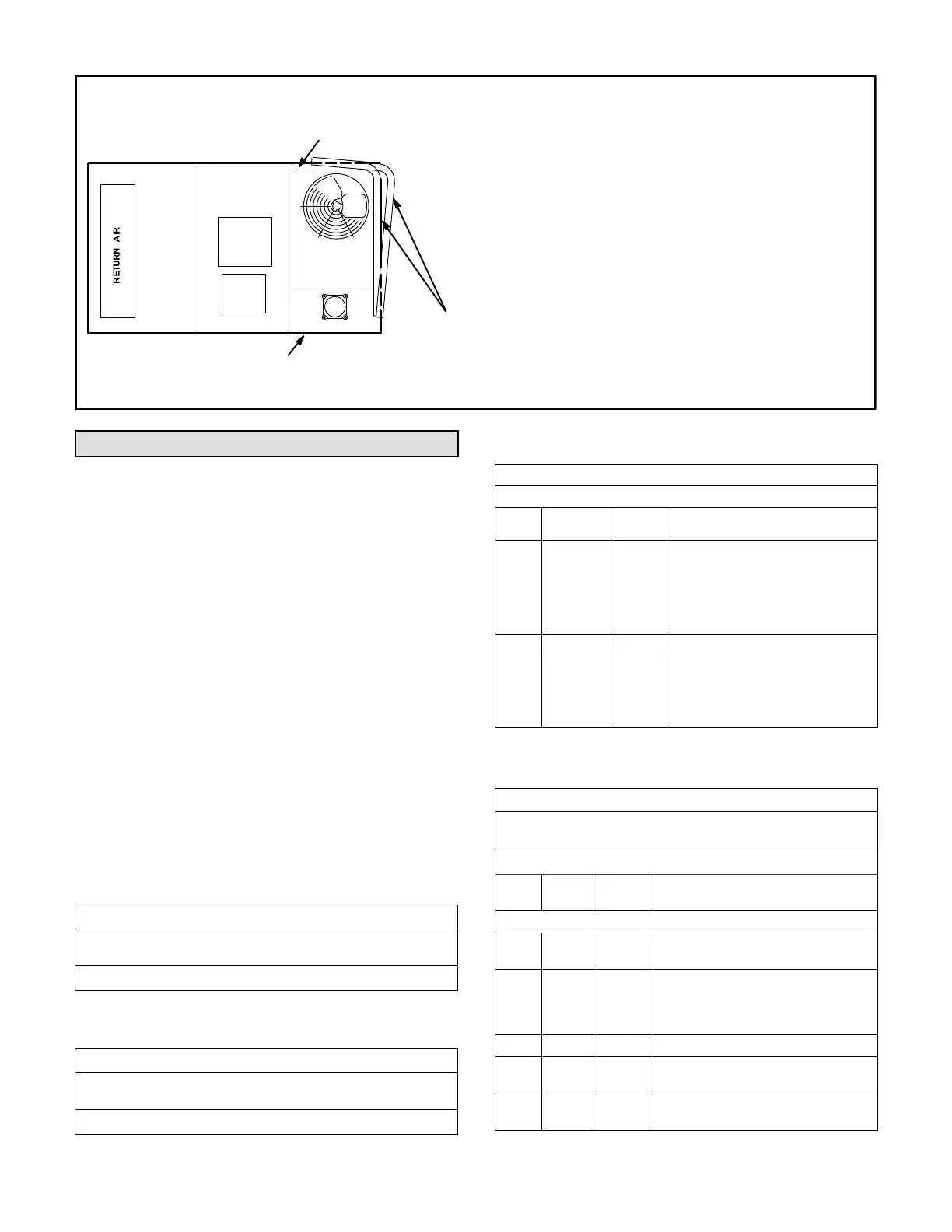

Factory Unit Controller Settings

Use the Unit Controller to adjust parameters; menu paths

are shown in each table. Refer to the Unit Controller

manual provided with each unit.

Tables 39 through 42 show factory settings (in degrees, %

of fan CFM, etc.). Record adjusted settings on the label

located inside the compressor access panel.

When field installing optional kits and accessories, the

Unit Controller must be configured to identify the option

before it will function. Refer to figures 38 and 39 to

determine whether the Unit Controller configuration I.D.

must change. To configure the option, use MAIN MENU >

SETUP > INSTALL menu path. Press SAVE until

CONFIGURATION ID 1 or 2 appears depending on the

option installed. Change the appropriate character in the

configuration I.D. For example, when an economizer is

installed using a single enthalpy sensor, change

configuration I.D. 1, the second character, to “S”.

TABLE 39

580730

Units With BACnet Module Settings

Use menu SETUP > NETWORK INTEGRATION. Set “BACNET” and

network address.

BACNET MAC ADDRESS:

TABLE 40

580732

Units With Room Sensor, CPC/LSE Gateway Settings

Use menu SETUP > NETWORK INTEGRATION. Set “L CONNEC

TION” and network address.

LCONN ADDRESS:

TABLE 41

580734

Units With Hot Gas Reheat

Use SETTINGS > RTU OPTIONS > EDIT PARAMETERS

Para

meter

Factory

Setting

Field

Setting

Description

105 6

Hot Gas Reheat Option 6: Reheat is

only possible if blower is energized

during occupied periods. Controlled

by RH sensor (A91) connected to

input A55_P298_5 and set point set

at parameter 106 (default 60%).

414

10 sec

(-036,

-048, -060

All-

Aluminum

Coils only)

HI CL REHEAT TMOUT:

Number of seconds Reheat Valve

remains energized upon thermo

stat call for high stage cooling

(default 0 seconds).

TABLE 42

580735

Units with BACnet Module (Target) Settings

Use menu SETUP > NETWORK INTEGRATION. Set “BACNET”

and network address.

BACNET MAC ADDRESS:

Para

meter

Factory

Setting

Setting Description

Use SETTINGS > RTU OPTIONS > EDIT PARAMETERS

91 120

Sets the compressor minimum run

time to 2 minutes.

106 99

Set reheat SP from connected sensor

to 99% to basically disable. Reheat

will be controlled over by BAS. Only

applies to units with the reheat option.

111 3 Thermostat with three cooling stages.

117 0

DCV max. open damper. 0=controlled

by network.

153 60

Time delay between heating and cool

ing mode.

Loading...

Loading...