Page 14

8 - If B-1 vent or an insulated exible vent pipe cannot

be used as liners, the chimney must be rebuilt

to accommodate one of these methods or some

alternate approved method must be found to vent the

appliance. When inspection reveals that an existing

chimney is not safe for the intended purpose, it

shall be rebuilt to conform to nationally recognized

standards, lined or relined with suitable materials

or replaced with a gas vent or chimney suitable for

venting unit heaters. The chimney passageway must

be checked periodically to ensure that it is clear and

free of obstructions.

REMOVAL OF UNIT FROM COMMON VENT

In the event that an existing unit heater is removed from a

venting system commonly run with separate gas applianc-

es, the venting system is likely to be too large to properly

vent the remaining attached appliances. The following test

should be conducted while each appliance is in operation

and the other appliances are not in operation, yet remain

connected to the common venting system. If the venting

system has been installed improperly, the system must be

corrected.

1 - Seal any unused openings in the common venting

system.

2 - Visually inspect the venting system for proper size and

horizontal pitch. Determine there is no blockage or

restriction, leakage, corrosion, or other deciencies

which could cause an unsafe condition.

3 - In so far as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliances

not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close

replace dampers.

4 - Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so

appliance will operate continuously.

5 - Test for spillage at the draft hood relief opening after

ve minutes of main burner operation. Use the ame

of a match or candle, or smoke from a cigarette,

cigar, or pipe.

6 - After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers

and any other gas-burning appliance to their previous

condition of use.

7 - If improper venting is observed during any of the above

tests, the common venting system must be corrected.

The common venting system should be resized to ap-

proach the minimum size as determined by using the

appropriate tables in Appendix G in the current editions

of the ANSI Z223-1, or the appropriate Category I Nat-

ural Gas and Propane appliances venting sizing tables

in the current standards of the CSA-B149 for installa-

tion compliance codes.

Electrical Connections

NOTE - Local codes may supersede any of the provisions

outlined in this instruction.

The LF25 series unit heaters use a direct spark ignition

system. There is no pilot necessary as the spark lights

the main burner as the gas valve is turned on. The di-

rect spark ignition control board emits radio noise as the

sparking process is under way. The level of energy may

be sucient to disturb a logic circuit in a microprocessor

controlled thermostat. It is recommended that an isola-

tion relay be used when connecting the unit heaters to a

microprocessor controlled thermostat. Install the thermo-

stat according to instructions provided. Install a separate

fused disconnect switch, with the fuse sized according to

blower motor size. Connect wiring through knockout on

the junction box located on the side of the unit heater. Re-

fer to dimensions in the front of this instruction for location.

Refer to heater wiring diagram for connection information.

Use 18 gauge wire or larger for thermostat connections.

NOTE - Electrically ground unit in accordance with local

codes or, in the absence of local codes, in accordance

with the current editions of the ANSI/NFPA No. 70, Na-

tional Electrical Code or CSA C22.1, Canadian Electrical

Code, Part 1.

NOTE - Uninsulated ground wires must be wrapped in

electrical tape to avoid damage to the electrical system.

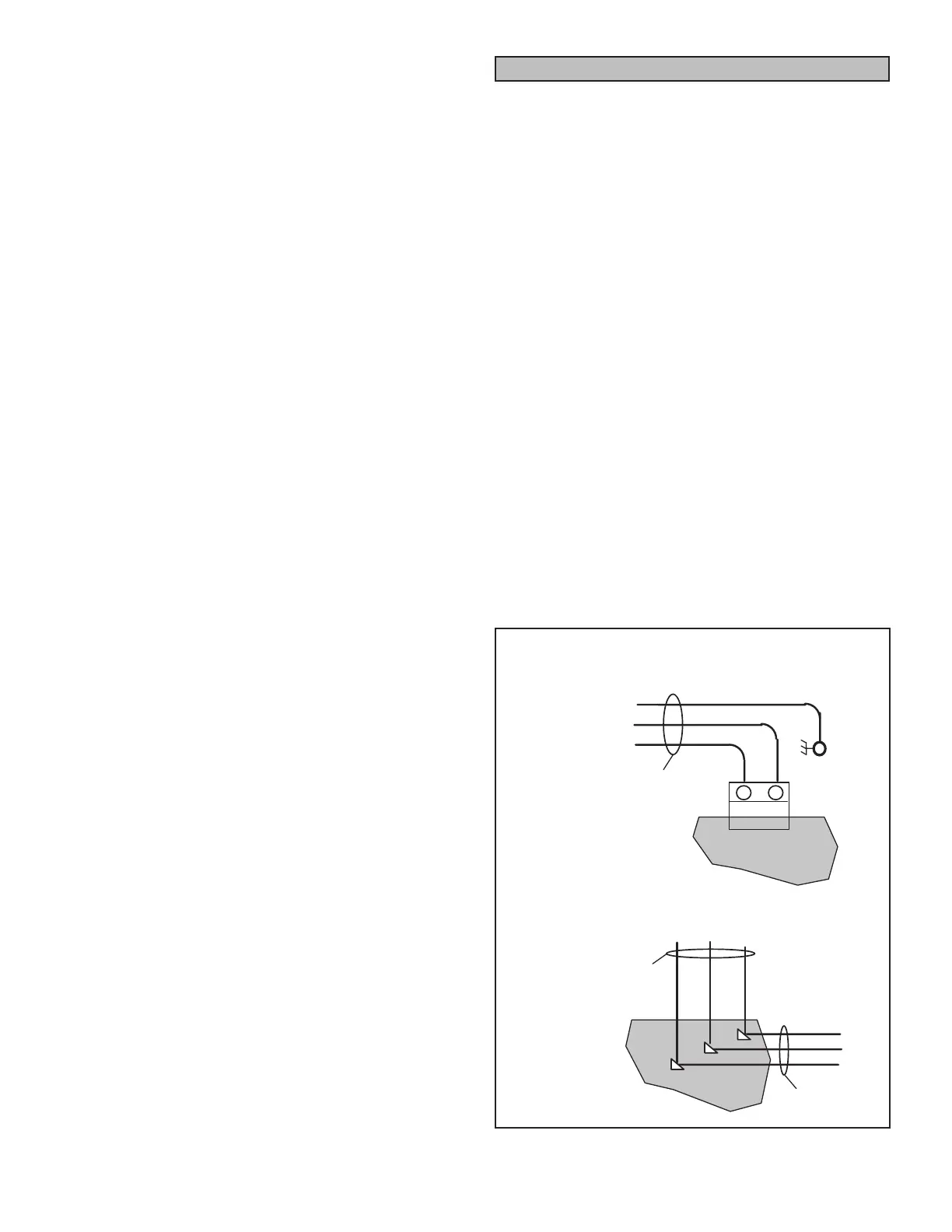

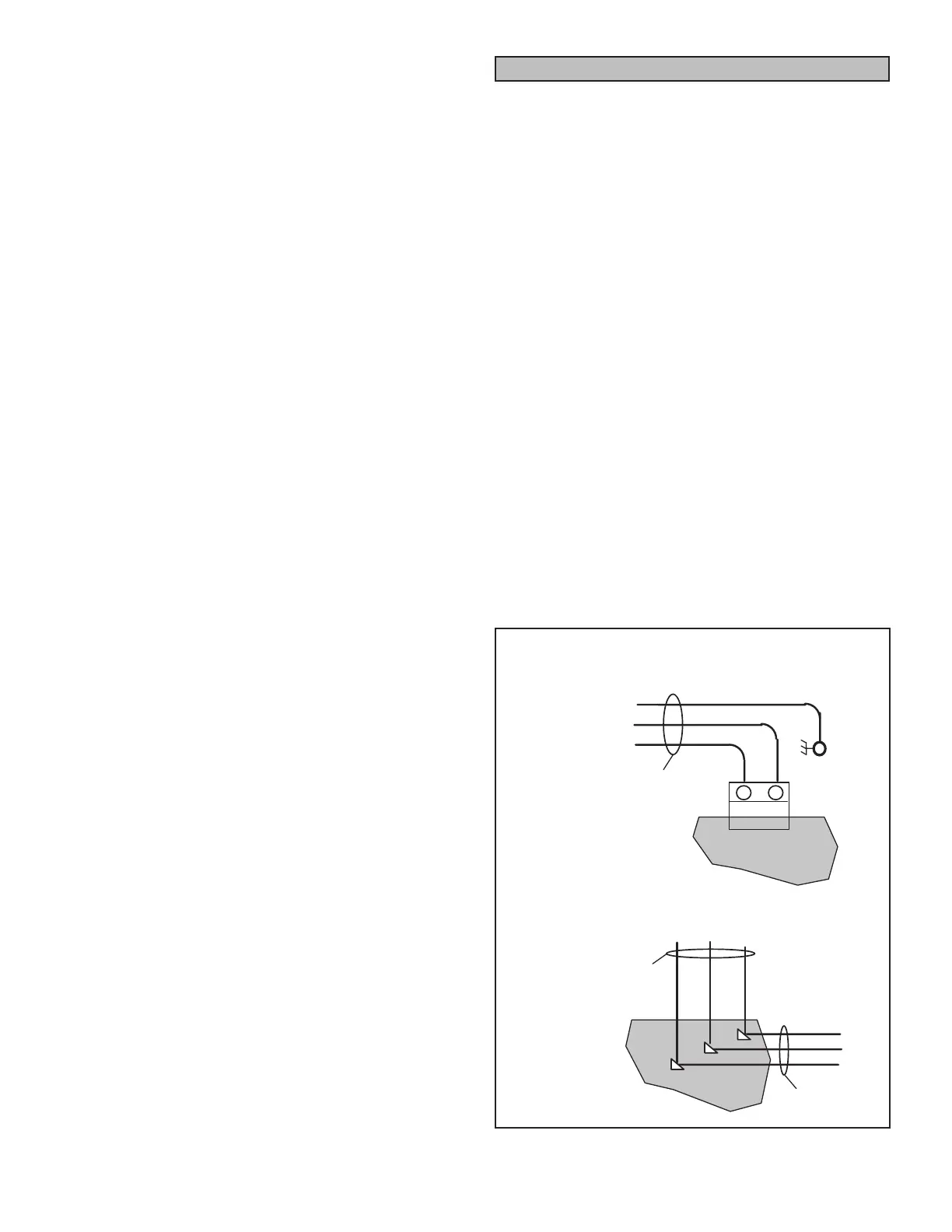

Make line voltage connections as shown in gure 7. Con-

nect eld wiring as shown on wiring diagram on unit. Also

refer to typical diagram in this manual. An additional ther-

mostat wire must be run to terminal “G” on heater when

continuous blower is desired.

HIGH VOLTAGE WIRING

A3 IGNITION

CONTROL

L1

N

GND

FIELD PROVIDED POWER WIRING.

CONNECT TO P366 ON A3 IGNI

TION CONTROL AND GREEN

GROUND SCREW NEAR A3.

GRN-YEL

WHT

BLK

125 / 400

030 / 105

POWER

ENTRY BOX

L1N

L1NGND

FIELD PROVIDED POWER

WIRING. MAKE FIELD

POWER CONNECTIONS

IN POWER ENTRY BOX

L1N

J366

P366

GRN-YEL

WHT

BLK

FACTORY

INSTALLED

FIGURE 7

Loading...

Loading...