Page 46

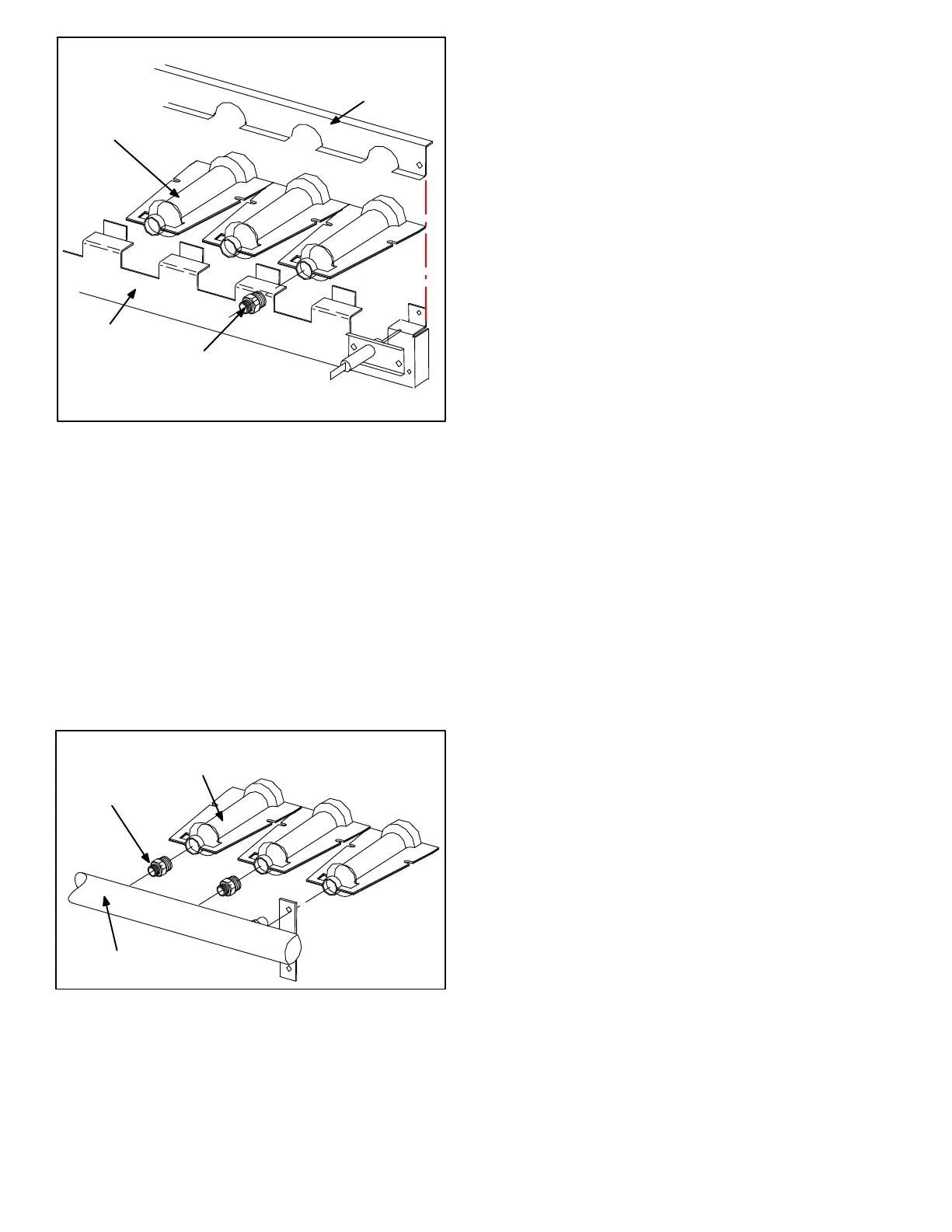

FIGURE 21

TYPICAL GAS BURNER ASSEMBLY

BURNERS

ORIFICE

BURNER

SUPPORT

BURNER

SUPPORT

CAP

Orifice

Each burner uses an orifice which is precisely matched to

the burner input. The orifice is threaded into the burner

manifold. The burner is supported by the orifice and will

easily slide off for service.

NOTE−Do not use thread sealing compound on the ori-

fices. Using thread sealing compound may plug the ori-

fices.

Each orifice and burner are sized specifically to the unit.

Refer to Lennox Repair Parts Listing for correct sizing in-

formation.

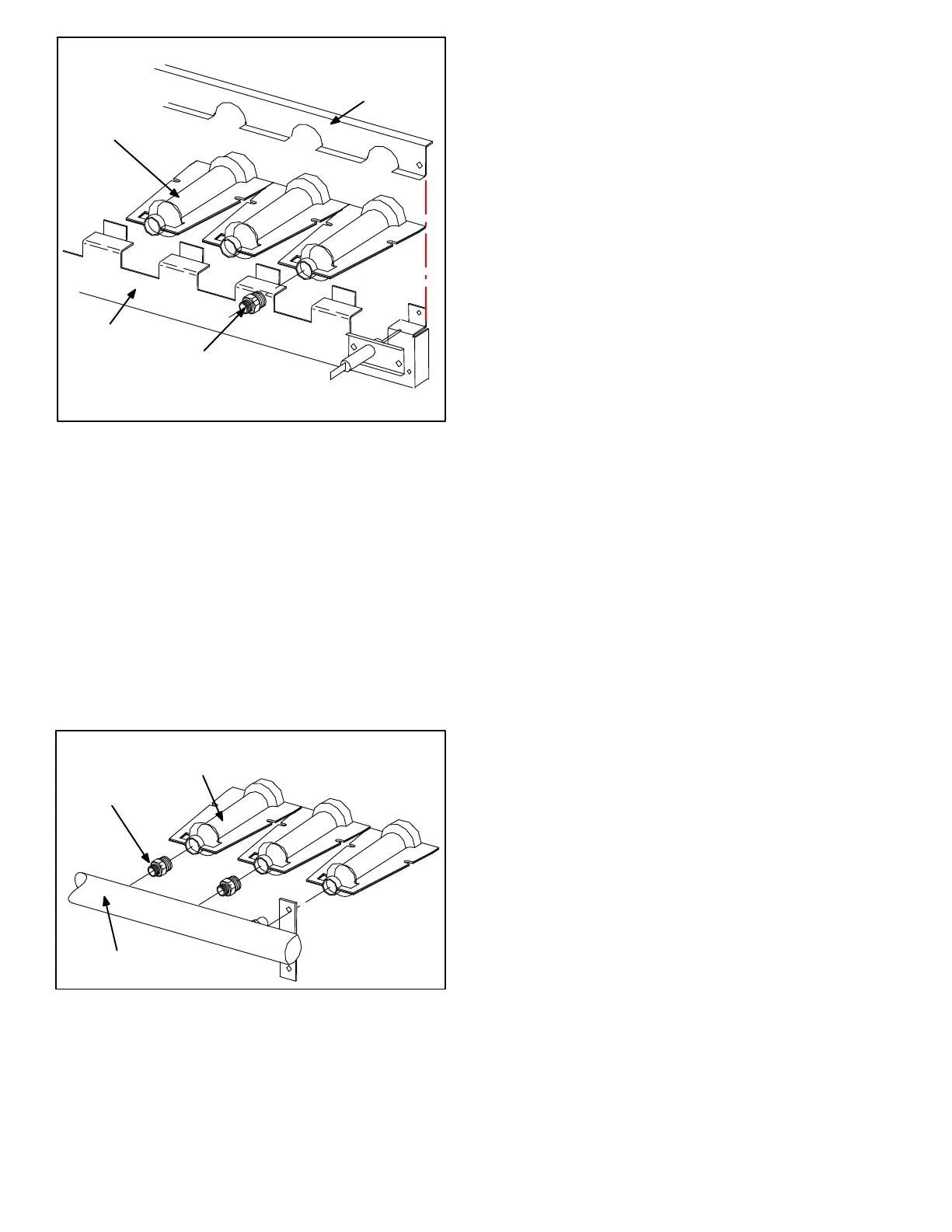

FIGURE 22

TYPICAL GAS MANIFOLD ASSEMBLY

BURNERS

MANIFOLD

ORIFICE

NOTE−In primary and secondary high temperature limits

S10, S99, S21, and S100 the ignition circuits in both gas

heat sections one and two are immediately de−energized

when terminals 1−3 open and the indoor blower mo-

tor is immediately energized when terminals 1−2

close. This is the primary and secondary safety shut−

down function of the unit.

4−Primary High Temperature Limits

S10 & S99

Figure 23 shows locations for temperature limits S10 and S99

on LGA/LCA models built up to production July 2004. S10 is

the primary high temperature limit for gas heat section one,

while S99 is the primary high temperature limit for gas heat

section two. S10 is located in the blower compartment and is

mounted on the end of the blower support panel which divides

the blower compartment from the heating compartment.

S99 is located on the blower support panel which separates

the second gas heat section from the outdoor condenser

section. S99 is accessed through a patch plate on the

condenser divider wall.

Figure 24 shows the location of production models August

2004 and later. S10 and S99 are located on the drip shield

behind the blower housing. In this location S10 and S99

serve as both primary and secondary limit.

Primary limit S10 is wired to the main control panel A55

which energizes burner 1 control (A3), while primary limit S99

is wired to the gas 2 panel A58 which energizes burner 2

control (A12). Its N.C. contacts open to de−energize the

ignition control when excessive temperature is reached in the

blower compartment. At the same time, the N.O. contacts of

S10 and S99 close energizing the blower relay coil K3 through

control A55. If either limit trips the blower will be energized.

Three limits with different actuating temperatures are

used for limits S10 and S99 (standard and high first heat

section use two different limits, while yet another limit is

used for the second heat section). All three limits are

SPDT N.C. auto−reset limits.

Limit set point are factory set and cannot be adjusted. If limit

must be repalced, same type and set point must be used. See

Lennox Repair Parts Handbook.

5−Secondary High Temperature Limits

S21 & S100 (Production to July 2004)

S21 is the secondary high temperature limit for heat sec-

tion one, while S100 is the secondary high temperature

limit for heat section two. Like the primary limits, the sec-

ondary limits are located in the blower compartment.

S21 and S100 are mounted on a horizontal panel lo-

cated behind the blowers (see figure 23).

Secondary limit S21 is also wired to the main control

panel A55, while secondary limit S100 is wired to the gas

2 panel A58. The secondary limits function in the same

manner as the primary limits, but are factory set to actu-

ate at different temperatures. The N.O. contacts of both

S21 and S100 are connected to the blower relay coil K3

through control A55. If either limit trips the blower will be

energized. All limits used are SPDT N.C. auto−reset lim-

its.

LGA/LGC units date coded August 2004 or later will not

be equipped with secondary limts S21 and S100.

Limit set point are factory set and cannot be adjusted. If limit

must be repalced, same type and set point must be used. See

Lennox Repair Parts Handbook.

Loading...

Loading...