Page 47

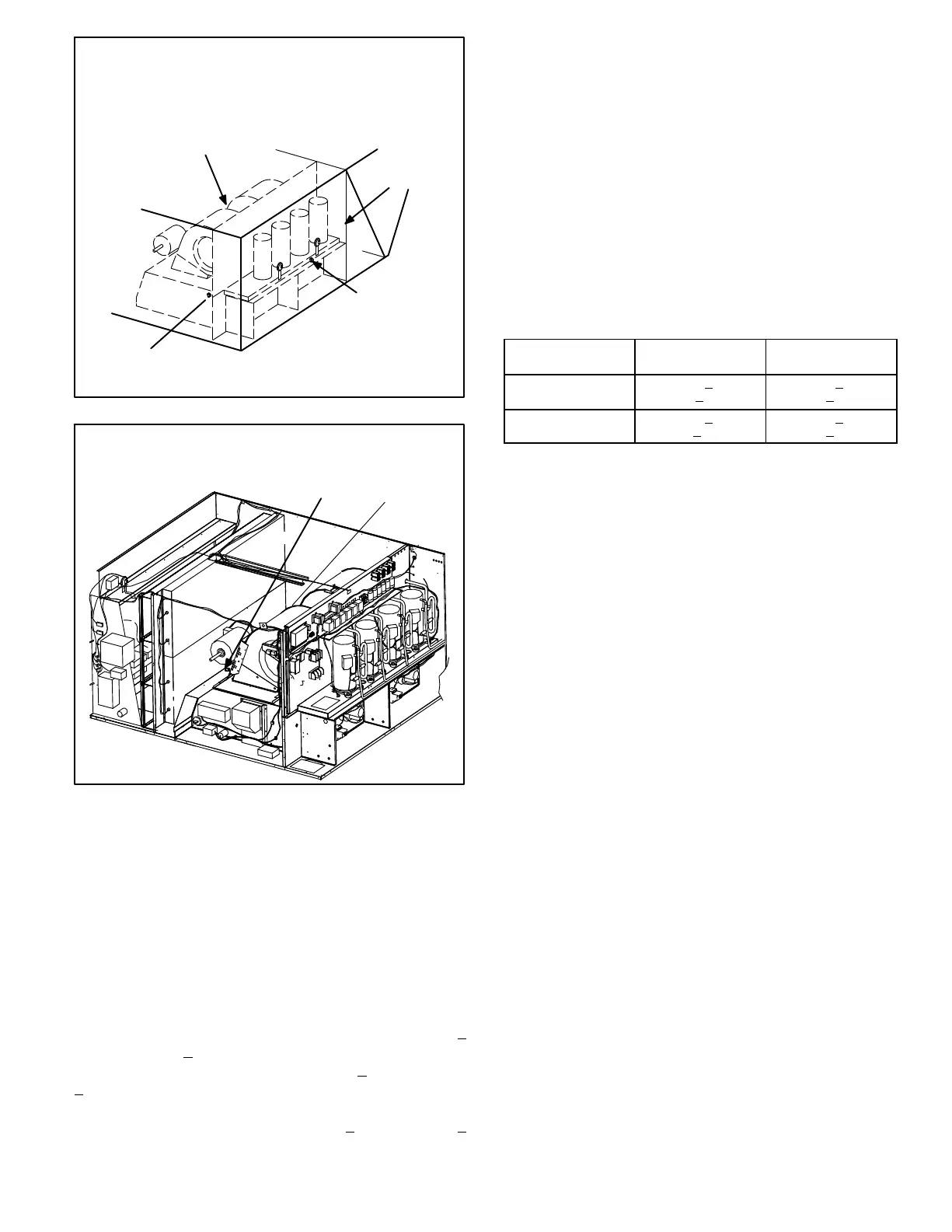

LGA/LGC HEATING COMPONENTS

(Production to July 2004)

FIGURE 23

PRIMARY HIGH

TEMP. LIMIT S99

(SECOND HEAT SECTION)

access patch plate is located

on condenser divider panel

PRIMARY HIGH

TEMP. LIMIT S10

(FIRST HEAT SECTION)

SECONDARY HIGH TEMP. LIMIT S21

FIRST HEAT SECTION and S100

(SECOND HEAT SECTION

HIDDEN BEHIND BLOWERS)

CONDENSER

DIVIDER PANEL

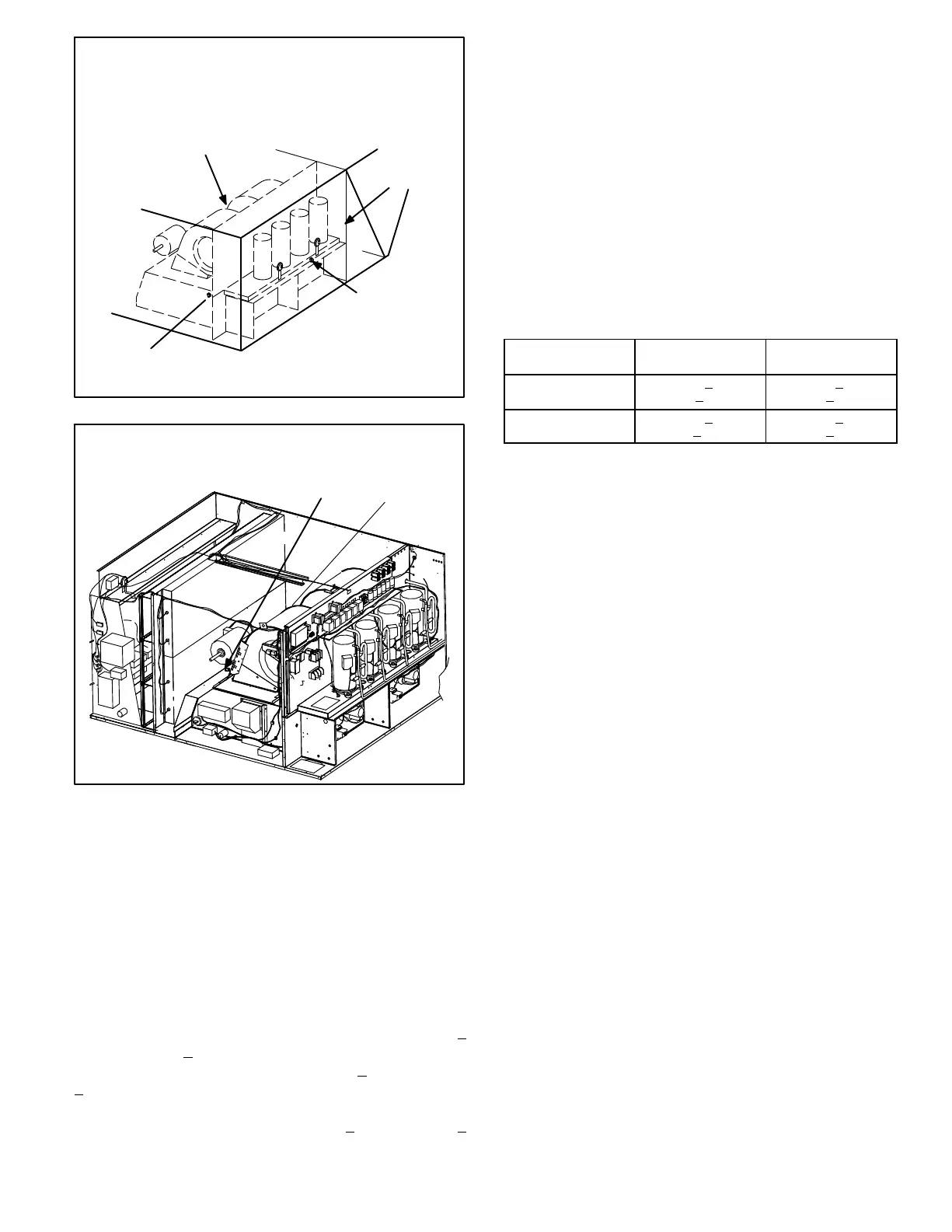

LGA/LGC HEATING COMPONENTS

(Production August 2004 and Later)

FIGURE 24

S10

S99

6−Flame Rollout Limits S47 and S69

Flame rollout limits S47 (first heat section) and S69 (sec-

ond heat section) are SPST N.C. high temperature limits lo-

cated just above the burner air intake opening in the burner en-

closures (see figure 16). S47 is wired to the main control panel

A55, while S69 is wired to the gas 2 panel A58. When S47 or

S69 senses flame rollout (indicating a blockage in the

combustion air passages), the corresponding flame rol-

lout limit trips, and the ignition control immediately

closes the gas valve.

For all units production to July 2004, limit S47 and S69 in

standard heat units are factory preset to open at 250_F +

12_F (121.1_C + 6.7_C) on a temperature rise, while on

high heat units both limits open at 270_F +

12_F (132.2_C

+

6.7_C) on a temperature rise. All flame rollout limits are-

manual reset. Production units August 2004; limit set point for

both standard heat and high heat is 290_F +

12_F (143.3_C +

6.7_C) .

7−Combustion Air Prove Switches S18 & S45

Prove switches S18 (first heat section) and S45 (second heat

section) are located in the compressor compartment. Switches

are identical, SPST N.O. and monitor combustion air inducer

operation. Switch S18 is wired to the main control panel A55,

while S45 is wired to the gas 2 panel A58. The switches

close on a negative pressure fall, allowing power to the igni-

tion controls. The switches open on a on a pressure rise

(less negative pressure). The combustion air prove

switches are factory set and not adjustable. Table 3 shows

prove switch settings for unit production dates before and

after February 2009.

TABLE 3

S18 & S45 Prove Switch Settings

Unit Production

Date

Close wc

(Pa)

Open wc

(Pa)

Feb 2009 & Later

0.25 + 5

(62.3+

12.4)

0.10+5

(24.8+

12.4)

Prior to Feb 2009

0.46+5

(114+12.4)

0.31+5

(77.2+12.4)

8−Combustion Air Inducers B6 and B15

Combustion air inducers B6 (first heat section) and B15 (sec-

ond heat section) are identical inducers which provide fresh air

to the corresponding burners while clearing the combustion

chamber of exhaust gases. The inducers begin operating

immediately upon receiving a thermostat demand and are

de−energized immediately when thermostat demand is sat-

isfied.

460V units date coded 10−2003 and after use a 460V inducer

motor and all other inducers use a 208/230V single-phase

PSC motor and a 4.81in. x 1.25in. (122mm x 32mm) blower

wheel. All motors operate at 3200RPM and are equipped with

auto-reset overload protection. Inducers are supplied by vari-

ous manufacturers. Ratings may vary by manufacturer. Spe-

cific inducer electrical ratings can be found on the unit rating

plate.

All combustion air inducer motors are sealed and can-

not be oiled. The inducer cannot be adjusted but can be

disassembled for cleaning.

9−Combustion Air Motor Capacitors C3 & C11

The combustion air inducer motors in all LGA/LGC units

require run capacitors. Capacitor C3 is connected to

combustion air inducer B6 and C11 is connected to com-

bustion air inducer B15. Both capacitors are rated at 3

MFD and 370VAC.

Loading...

Loading...