Page 13

LGH/LCH036, 048, 060, 072, 074

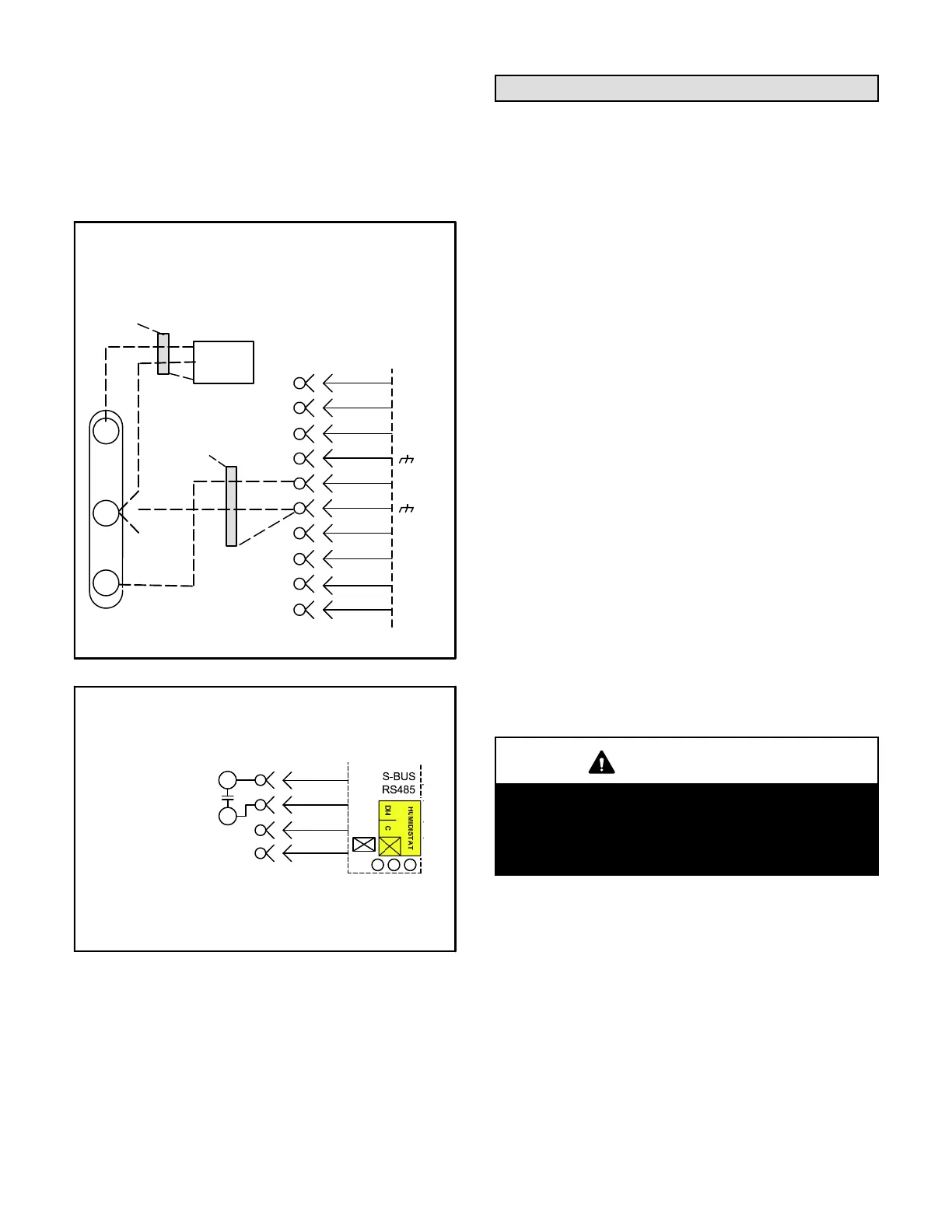

Wire runs over 150 feet (mm):

Use a local, isolated 24VAC transformer such as

Lennox cat #18M13 (20VA minimum) to supply power

to RH sensor as shown in figure 17. Use two shielded

cables containing 20AWG minimum, twisted pair

conductors with overall shield. Belden type 8762 or

88760 (plenum) or equivalent.

FIGURE 17

FIELD WIRING REHEAT UNITS

(Using A Humidity Sensor With

More than 150 Ft. Wire Runs)

ISOLATED 24V

TRANSFORMER

9

8

P298

J298A

1

2

B

3

4

C

5

6

7

D

10

A91

VIN

VO

GND

R

C

AI-1

HUM

TMP

DO-1

C

DI-1

DO-2

NOT

CONNECTED

NOT

CONNECTED

DRAIN

A55 UNIT

CONTROLLER

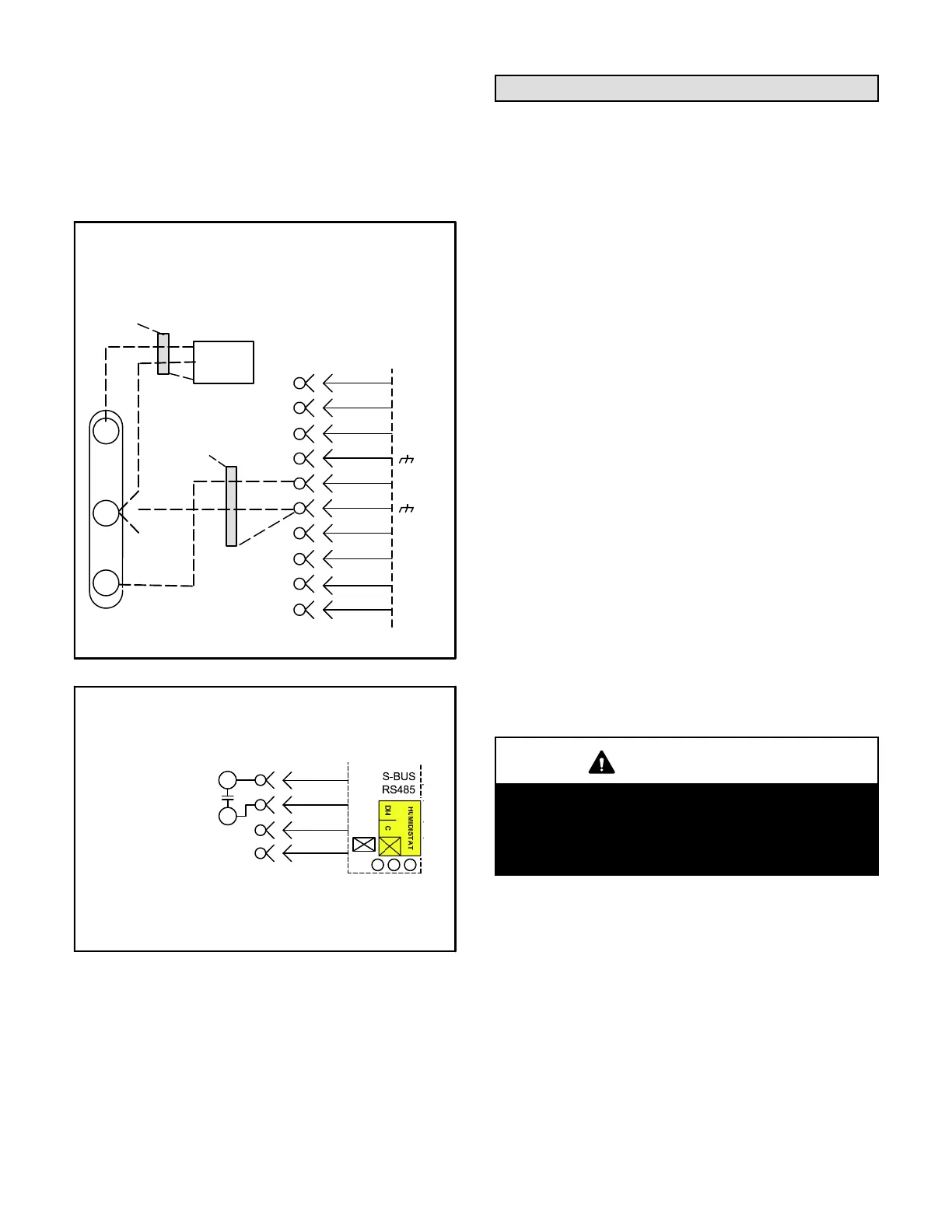

FIGURE 18

FIELD WIRING REHEAT UNITS

(Using A Dehumidification Switch)

7

10

8

9

R

DI−4

C

Use 24 VAC (R) from any terminal

available on J299−2, −5, or −7.

J299

DEHUMIDIFICATION

SWITCH

Blower Operation and Adjustments

Units are equipped with one of three factory-installed

blower options. The ninth character in the model number

identifies the blower as follows:

E= High efficiency three-, four- and five-ton units are

equipped with a variable speed, direct drive blower.

When these units are also equipped with an

economizer and configured for Advanced Air Flow

Control, the installer is able to enter the

design-specified supply and outdoor air CFM into

the Unit Controller. This eliminates the need to

manually take measurements and adjust settings.

See Advanced Air Flow Control Start-Up section.

Ultra high efficiency units are also equipped with a

variable speed, direct drive blower. The installer is

able to enter the design-specified supply air CFM

into the Unit Controller for optimal efficiency. The

Unit Controller calibrates the supply air volume

which eliminates the need to manually take duct

static measurements. Refer to D-Adjusting Unit

CFM - Ultra High Efficiency Direct Drive Blowers.

T= Units are equipped with a two-stage belt drive blower.

B= Units are equipped with a single-stage belt drive

blower.

Note - Six-ton, non-ultra high efficiency units are

available with belt drive blowers only.

IMPORTANT

Three phase scroll compressors must be phased

sequentially for correct compressor and blower

rotation. Follow “COOLING START-UP” section of

installation instructions to ensure proper compres

sor and blower operation.

Loading...

Loading...