Page 47

II-PLACEMENT AND INSTALLATION

Make sure the unit is installed in accordance with the in

stallation instructions and all applicable codes. See ac

cessories section for conditions requiring use of the op

tional roof mounting frame (C1CURB10).

III-CHARGING

WARNING

Refrigerant can be harmful if it is inhaled. Refrigerant

must be used and recovered responsibly.

Failure to follow this warning may result in person

al injury or death.

IMPORTANT

Units equipped with a Hot Gas Reheat system MUST be

charged in standard cooling mode.

A-Refrigerant Charge and Check - All-Aluminum Coil

092H, 102H, 120H, 150S Units

WARNING-Do not exceed nameplate charge under any

condition.

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant, re

claim the charge, evacuate the system, and add required

nameplate charge.

NOTE - System charging is not recommended below 60_F

(15_C). In temperatures below 60_F (15_C), the charge

must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

IMPORTANT - Charge unit in standard cooling mode.

1- Make sure outdoor coil is clean. Attach gauge manifolds

and operate unit at full CFM in cooling mode with econo

mizer disabled until system stabilizes (approximately five

minutes). Make sure all outdoor air dampers are closed.

2- Check each system separately with all stages operat

ing. Compare the normal operating pressures (see ta

bles 5 - 8) to the pressures obtained from the gauges.

Check unit components if there are significant differ

ences.

3- Measure the outdoor ambient temperature and the suc

tion pressure. Refer to the appropriate circuit charging

curve to determine a target liquid temperature.

Note - Pressures are listed for sea level applications.

4- Use the same thermometer to accurately measure the

liquid temperature (in the outdoor section).

D If measured liquid temperature is higher than the

target liquid temperature, add refrigerant to the

system.

D If measured liquid temperature is lower than the

target liquid temperature, recover some refrigerant

from the system.

5- Add or remove charge in increments. Allow the system

to stabilize each time refrigerant is added or removed.

6- Continue the process until measured liquid tempera

ture agrees with the target liquid temperature. Do not

go below the target liquid temperature when adjusting

charge. Note that suction pressure can change as

charge is adjusted.

7- Example LGH/LCH092 Circuit 1: At 95°F outdoor am

bient and a measured suction pressure of 130psig, the

target liquid temperature is 96°F. For a measured liquid

temperature of 106°F, add charge in increments until

measured liquid temperature agrees with the target liq

uid temperature.

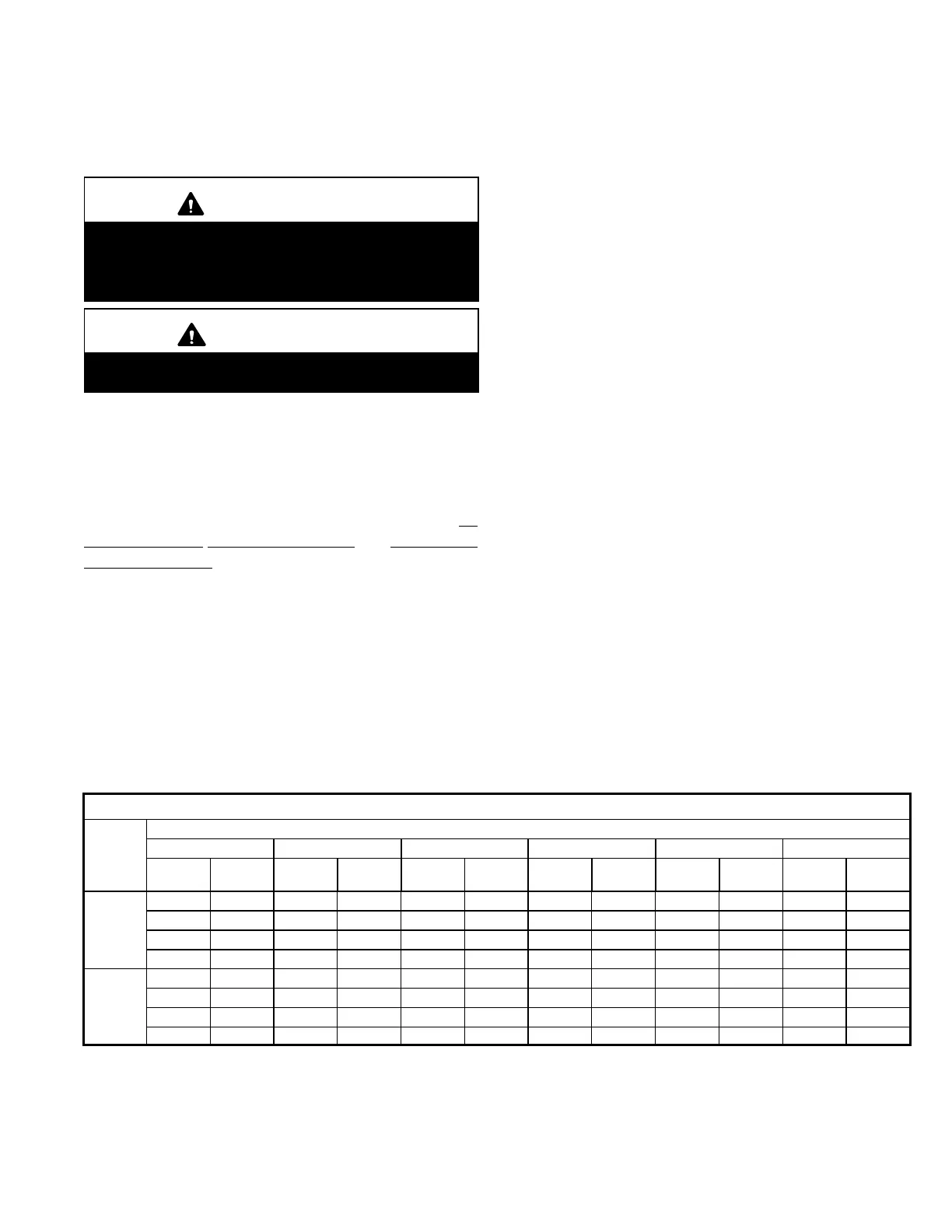

TABLE 5

LGH/LCH092H Normal Operating Pressures - All-Aluminum - TXV

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Circuit 1

110 234 112 273 115 317 116 367 119 428 121 503

118 236 120 275 123 319 125 369 127 426 130 497

136 240 139 278 142 320 145 369 147 422 150 483

157 248 159 284 163 325 166 373 168 424 171 482

Circuit 2

112 232 115 269 117 313 118 371 120 441 122 523

119 237 122 273 125 316 128 367 129 431 132 508

134 243 139 279 143 320 146 370 149 424 151 488

155 253 156 287 161 328 165 376 169 427 172 487

Loading...

Loading...