Page 25

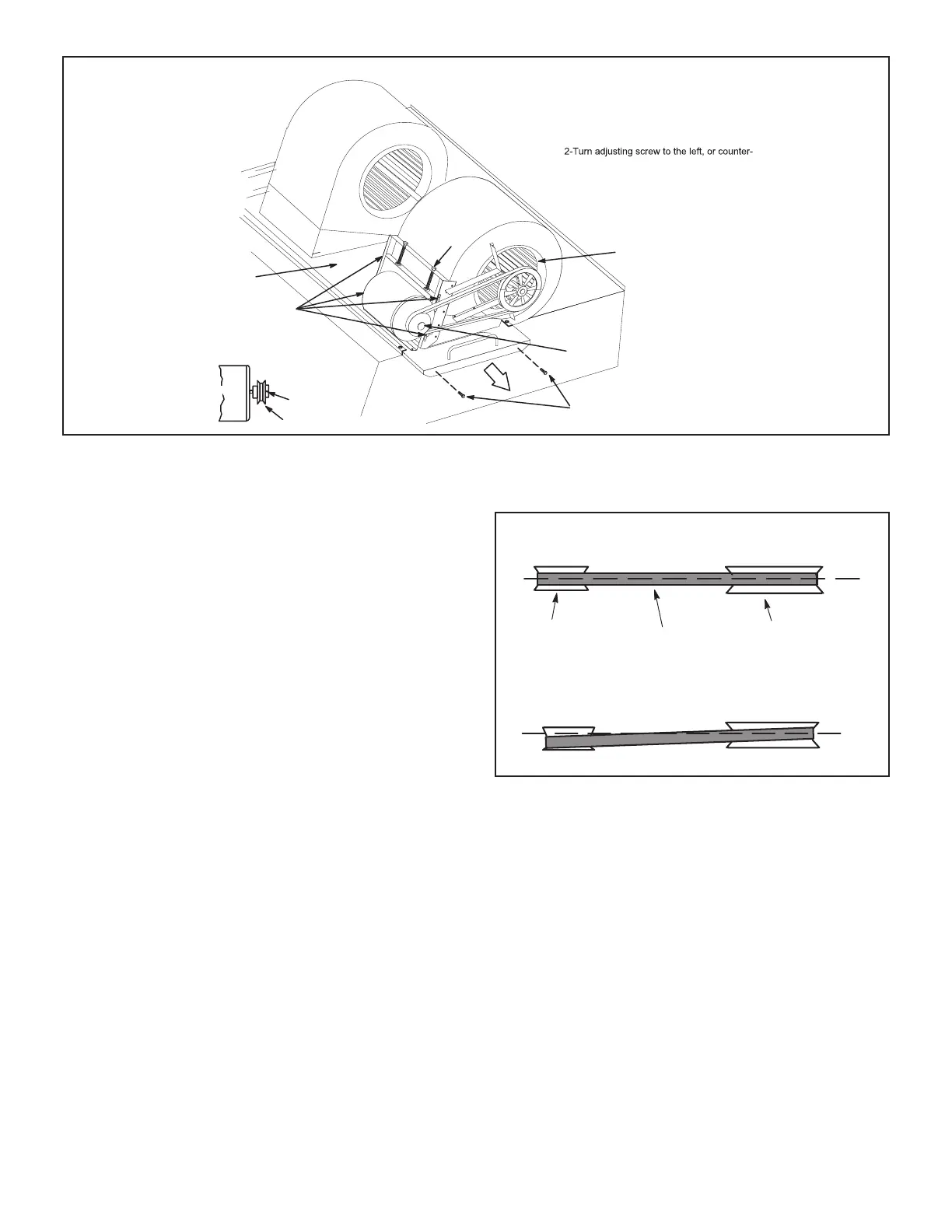

BLOWER ASSEMBLY - NO TENSIONER

TO INCREASE BELT TENSION

1-Loosen four screws securing blower motor to

sliding base.

clockwise, to move the motor downward and

tighten the belt.

3-Tighten four screws.

TO INCREASE CFM

LOOSEN ALLEN SCREW &

TURN PULLEY CLOCKWISE

TO DECREASE CFM

TURN PULLEY

COUNTERCLOCKWISE

BLOWER

WHEEL

BLOWER

MOTOR

PULLEY

BLOWER

ASSEMBLY

SLIDING BASE

BELT TENSION

ADJUSTING

SCREW

LOOSEN (4) SCREWS TO

ADJUST BELT TENSION

REMOVE SCREWS TO

SLIDE BLOWER

ASSEMBLY OUT OF UNIT

PULLEY

MOTOR

ALLEN

SCREW

SIDE VIEW

FIGURE 12

D-Blower Belt Adjustment

proper pulley alignment and belt tension are maintained.

This will allow belt to stretch and seat into pulley grooves.

-

-

ure 14 for units equipped with an optional belt tensioner.

Blowers Without Belt Tensioner

1 - Loosen four screws securing blower motor to sliding

2 - To increase belt tension -

the distance between the blower motor and the

blower housing.

3 - To loosen belt tension -

loosen belt tension. 3- Tighten four screws securing

blower motor to sliding base once adjustments have

been made.

PULLEY ALIGNMENT - NO TENSIONER

BELT

BLOWER

PULLEY

MOTOR

PULLEY

NOT ALIGNED

ALIGNED

FIGURE 13