Page 27

D-OPTIONAL ELECTRIC HEAT

See ELECTRICAL / ELECTRIC HEAT DATA and ELEC-

TRIC HEAT CAPACITIES (table of contents) for LCH to

EHA match-ups and electrical ratings.

All electric heat sections consist of electric heating el-

-

to thermostat demand.

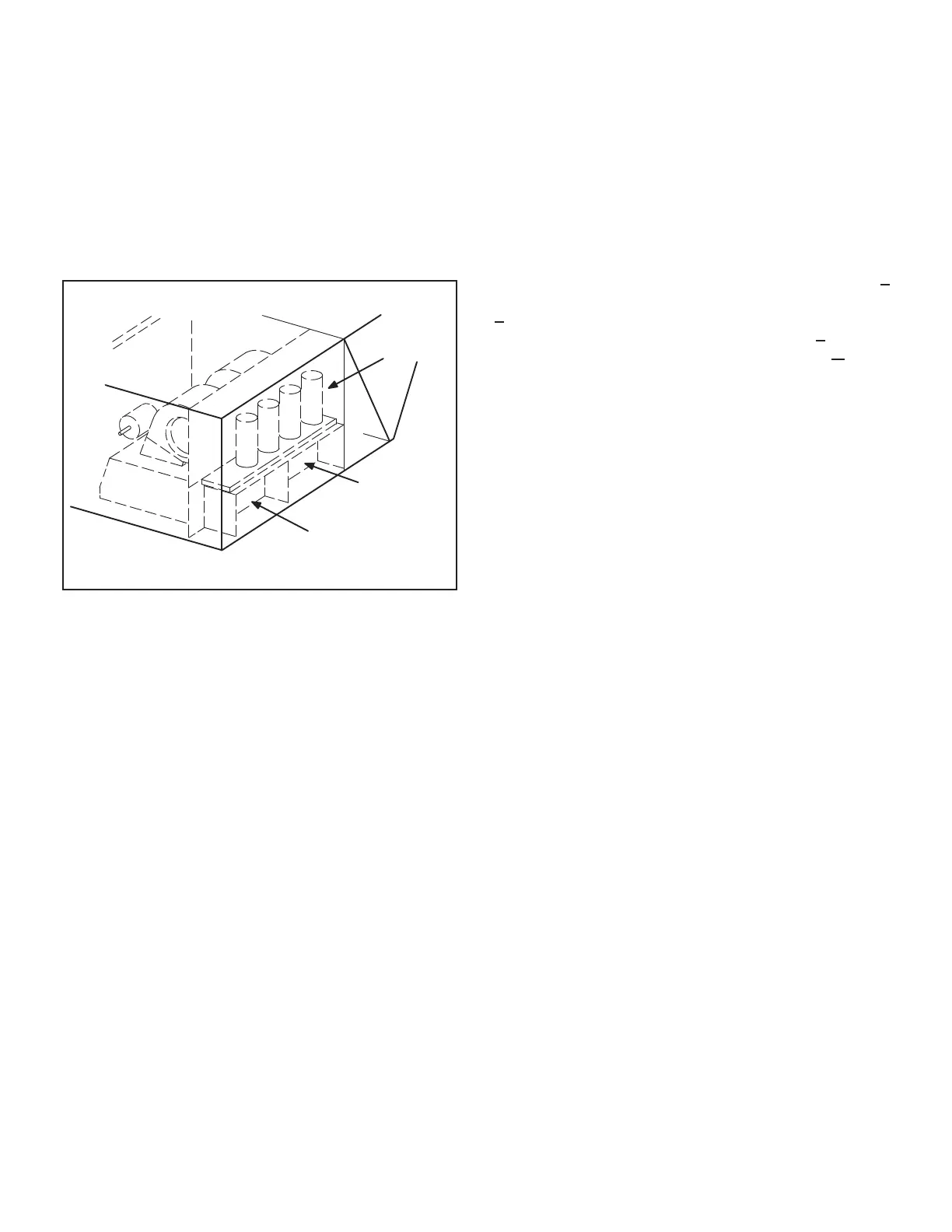

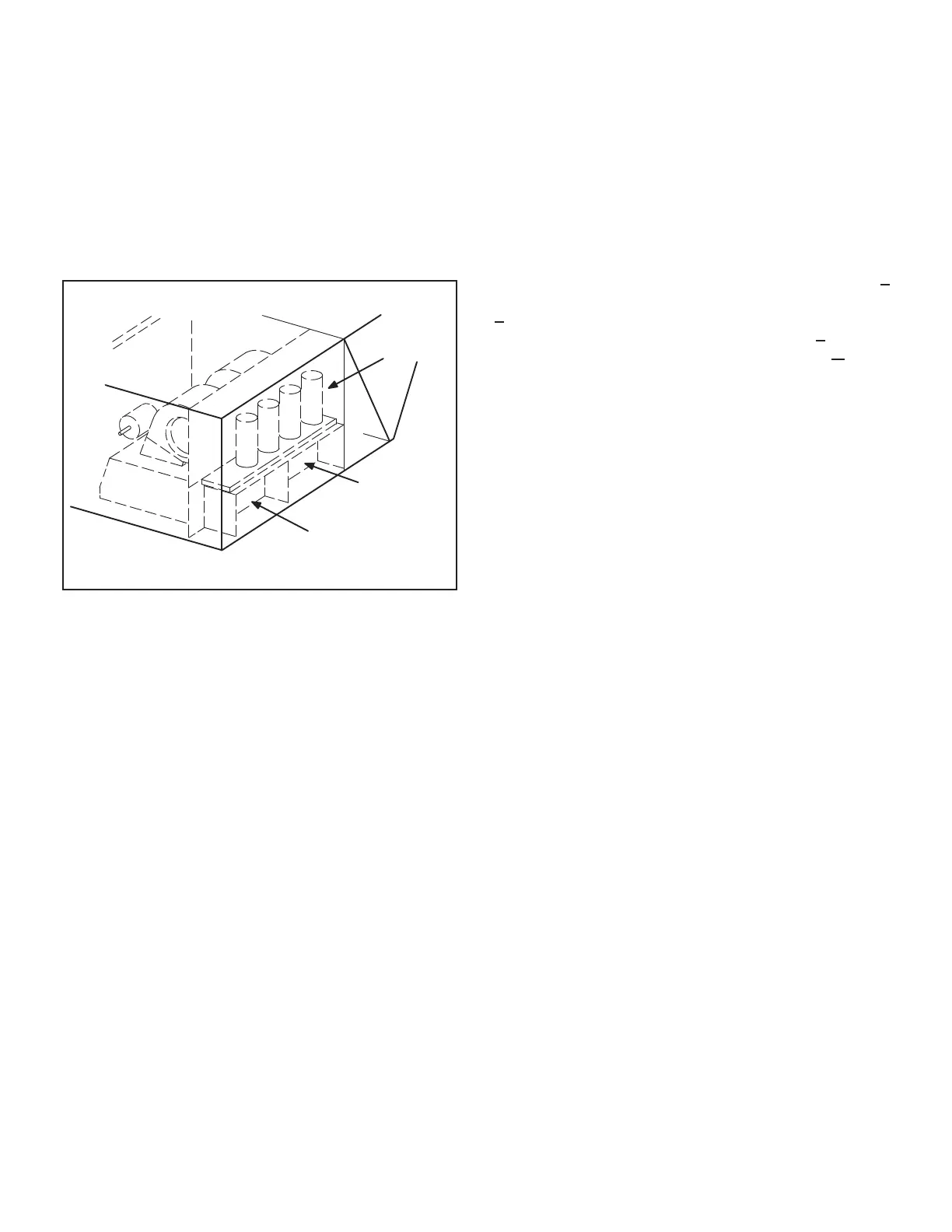

HEAT SECTION PLACEMENT

FIRST ELECTRIC

HEAT SECTION

(LEFT SIDE)

SECOND ELECTRIC

HEAT SECTION

(RIGHT SIDE)

COMPRESSOR

COMPARTMENT

FIGURE 16

1-Main Control Box Components A55, K9

Controller and the K9 electric heat relay.

2-Contactors K15, K16, K17 and K18

-

ble-break contactors located on the electric heat vestibule.

section houses all contactors and fuses. All contactors are

-

stage heating elements.

3-High Temperature Limits S15 and S107 (Primary)

S15 and S107 are SPST N.C. auto-reset thermostats lo-

cated on the back panel of the electric heat section below

the heating elements. S15 is the high temperature limit

temperature limit for the second electric heat section. Both

thermostats are identical and are wired to the A55 Unit

stages of heat are de-energized. The thermostats used

+

+

thermostats are factory set to open at 170 F + 5 F on a

temperature rise and automatically reset at 130 F +

a temperature fall. The thermostats are not adjustable.

4-Terminal Strip TB3

Electric heat line voltage connections are made to termi-

nal strip TB3 (or a fuse block on some models) located in

the upper left corner of the electric heat vestibule.

5-Heating Elements HE1 through HE14

-

-

ments are connected in a three-phase arrangement. The

-

-

ed in “Wye” arrangement.

Each stage is energized independently by the correspond-

ing contactors located on the electric heat vestibule panel.

-

perature protection is provided by primary and redundant

high temperature limits and overcurrent protection is pro-

vided by fuses.

6-Fuse F3

Fuse F3 are housed in a fuse block which holds three fus-

es. Each F3 fuse is connected in series with each leg of

Loading...

Loading...