10 11

5. AIR PURGING AND TEST OPERATION

1. Air Purging

• Air and moisture in the refrigerant system have undesirable effects. Therefore the indoor unit and tubing between the

indoor and outdoor unit must be leak tested and evacuated to remove any non-condensables and moisture from the

system.

• Check that each tube (both liquid and gas side tubes) between the indoor and outdoor units have been properly connected

and all wiring for the test run has been completed.

• Pipe length and refrigerant amount:

Connective pipe length Air purging method Additional amount of refrigerant to be charged

Less than 5m Use vacuum pump - -

More than 5m Use vacuum pump Liquid side ∅6.35mm

R22: (pipe length -5) x 30g/m

R410A: (pipe length -5) x 20g/m

Liquid side ∅9.52mm

R22: (pipe length -5) x 60g/m

R410A: (pipe length -5) x 40g/m

• For the R407C refrigerant model, make sure the refrigerant added into the air conditioner is in liquid form.

• When relocating the unit to another place, use a vacuum pump to perform an evacuation.

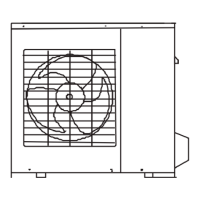

2. When using the Vacuum Pump

1. Completely tighten the fl are nuts A, B, C, D, connect

the manifold valve charge hose to a charge port of the

packed valve on the gas pipe side.

2. Connect the charge hose connection to the vacuum

pump.

3. Fully open the handle Lo of the manifold valve.

4. Operate the vacuum pump to evacuate. After starting

evacuation, slightly loosen the fl are nut of the packed

valve on the gas pipe side and check that the air is

entering. (Operation noise of the vacuum pump changes

and a compound meter indicates 0 instead of minus).

CAUTION

• Open the valve stem until it hits against the

stopper. Do not try to open it further.

• Securely tighten the valve stem cap with a

spanner or the like.

• Valve stem cap tightening torque. See Tightening

torque table (p9).

CAUTION

A: Lo packed valve

B: Hi packed valve C and D are ends of indoor unit

connection.

Flare nut

Stopper

Cap

Valve bo dy

Valv e s tem

Outdoor

unit

Indo or

unit

Refri ge rant

Packe d val ve

Ha lf un ion

Gas side

Liquid side

A

C

D

B

5. After the evacuation is complete, fully close the handle Lo of the manifold valve and stop the operation of the

vacuum pump.

• Evacuate for 15 minutes or until the compound meter indicates -76cmHg (-1.0 x 10

5

Pa).

6. Turn the stem of the packed valve B about 45º counter-clockwise for 6-7 seconds after the gas coming out, then tighten

the fl are nut again. Make sure the pressure display in the pressure indicator is a little higher than the atmospheric

pressure.

7. Fully open the packed valve stems B and A.

8. Securely tighten the cap of the packed valve.

Manifold valve

Compound meter

-76cmHg

Handle Lo

Handle Hi

Charge hose

Charge hose

Vacuum p u mp

Pressure gauge

Packed valve

Indoor unit

check p oint

D

B

C

A

Outdoor unit

check p oint

Cove r

3. Safety and leakage check

1. Soapy water method:

Apply soapy water or a liquid neutral detergent on the

indoor unit connections and outdoor unit connections

by a soft brush to check for leakage of the connecting

points of the piping. If bubbles come out, it indicates that

the pipes have leakage.

2. Leak Detector:

Use the leak detector to check for leakage.

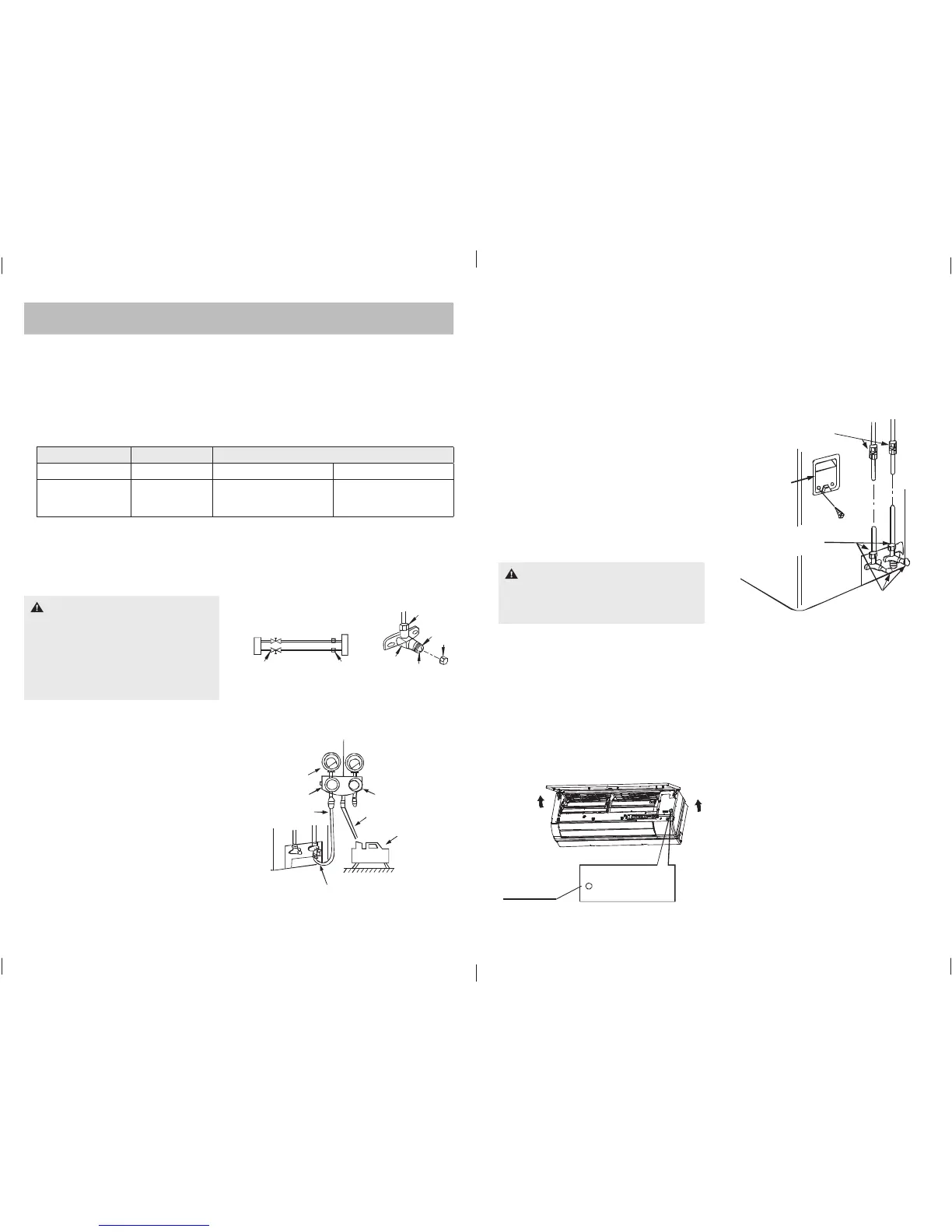

4. Running a preliminary test

Perform a test operation after completing gas leak check at

the fl are nut connections and electrical safety check.

• Check that all tubing and wiring have been properly

connected.

• Check that the gas and liquid side service valves are

fully open.

Manual contro l

button

AU TO/ COO L

1. Connect the power, press the ON/OFF button on the

remote controller to turn the unit on.

2. Use the MODE button to select COOL, HEAT, AUTO and

FAN to check if all the functions work well.

3. When the ambient temperature is too low (lower than

17ºC), the unit cannot be controlled by the remote

controller in the cooling mode – manual operation must

occur. Manual operation is used only when the remote

controller is disabled or maintenance is necessary.

• Hold the panel sides and lift the panel up to an angle

until it remains fi xed with a clicking sound.

• Press the Manual control button to select the AUTO

or COOL, the unit will operate under Forced AUTO or

COOL mode (see User Manual for details).

4. The test operation should last about 30 minutes.

E963_Lennox Split Wall Mounted Installation Manual 12pp A5 1c.indd 10-11E963_Lennox Split Wall Mounted Installation Manual 12pp A5 1c.indd 10-11 9/12/11 11:47 AM9/12/11 11:47 AM

Loading...

Loading...