Page 22

D−Extended Period Shutdown

Turn off thermostat or set to UNOCCUPIED" mode.

Close all shutoff valves in the oil supply line to guarantee no

oil leaks into burner. Turn off all power to unit. All access

panels, covers and vent caps must be in place and se

cured.

IV−HEATING SYSTEM SERVICE CHECKS

A−Oil Piping

All oil supply piping (factory and field) must be carefully

checked for oil leaks.

B−Electrode Adjustment

When adjusting the electrode, use the AFII multipurpose

gauge (Beckett part # T−500) packaged with each oil fur

nace, also available from Beckett.

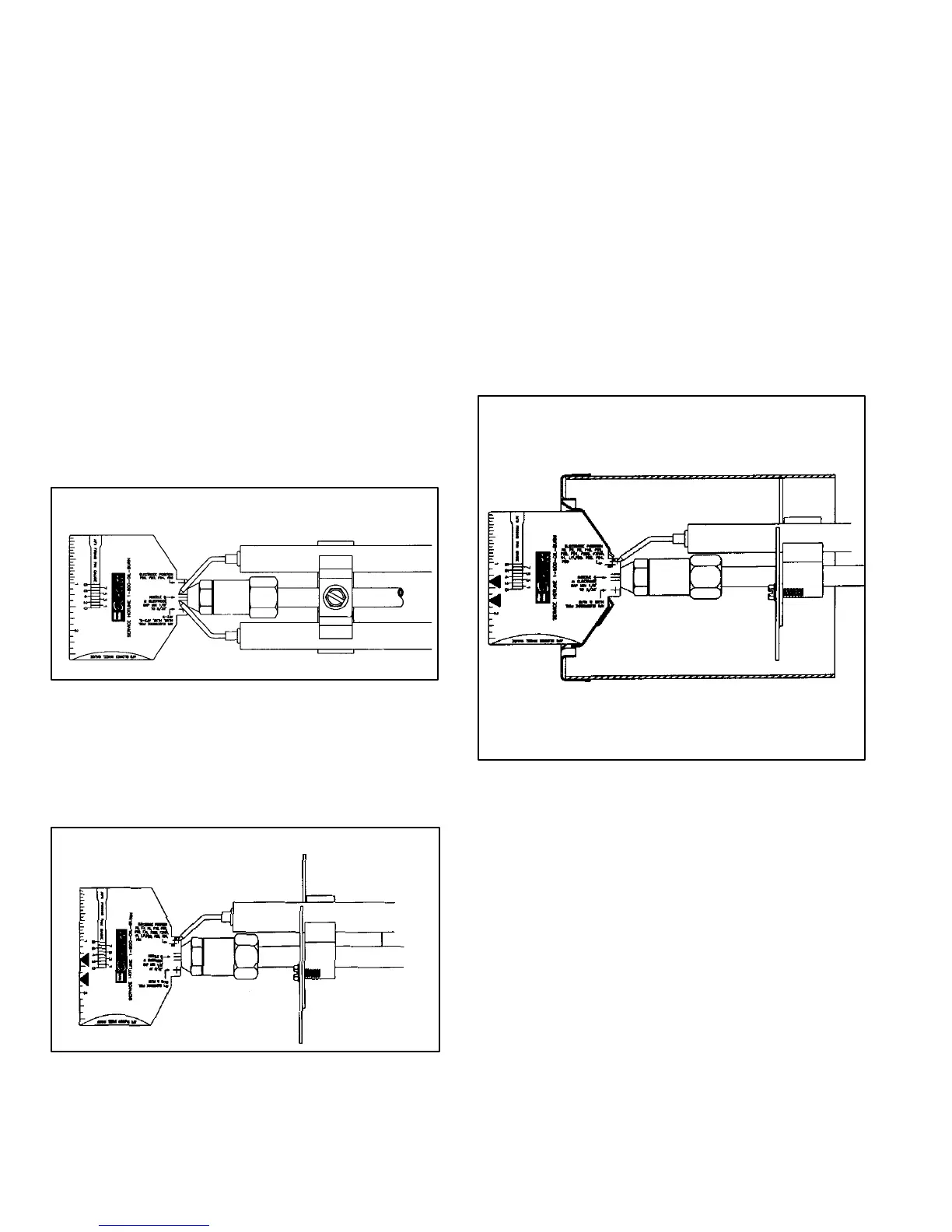

To set the electrode tip gap spacing, position the gauge as

shown in figure 25. Align the center mark with the nozzle

and adjust the electrodes to the two outer marks (1/8"

[3mm] to 1/16" [2mm] minimum).

FIGURE 25

AFII ELECTRODE TIP

GAP

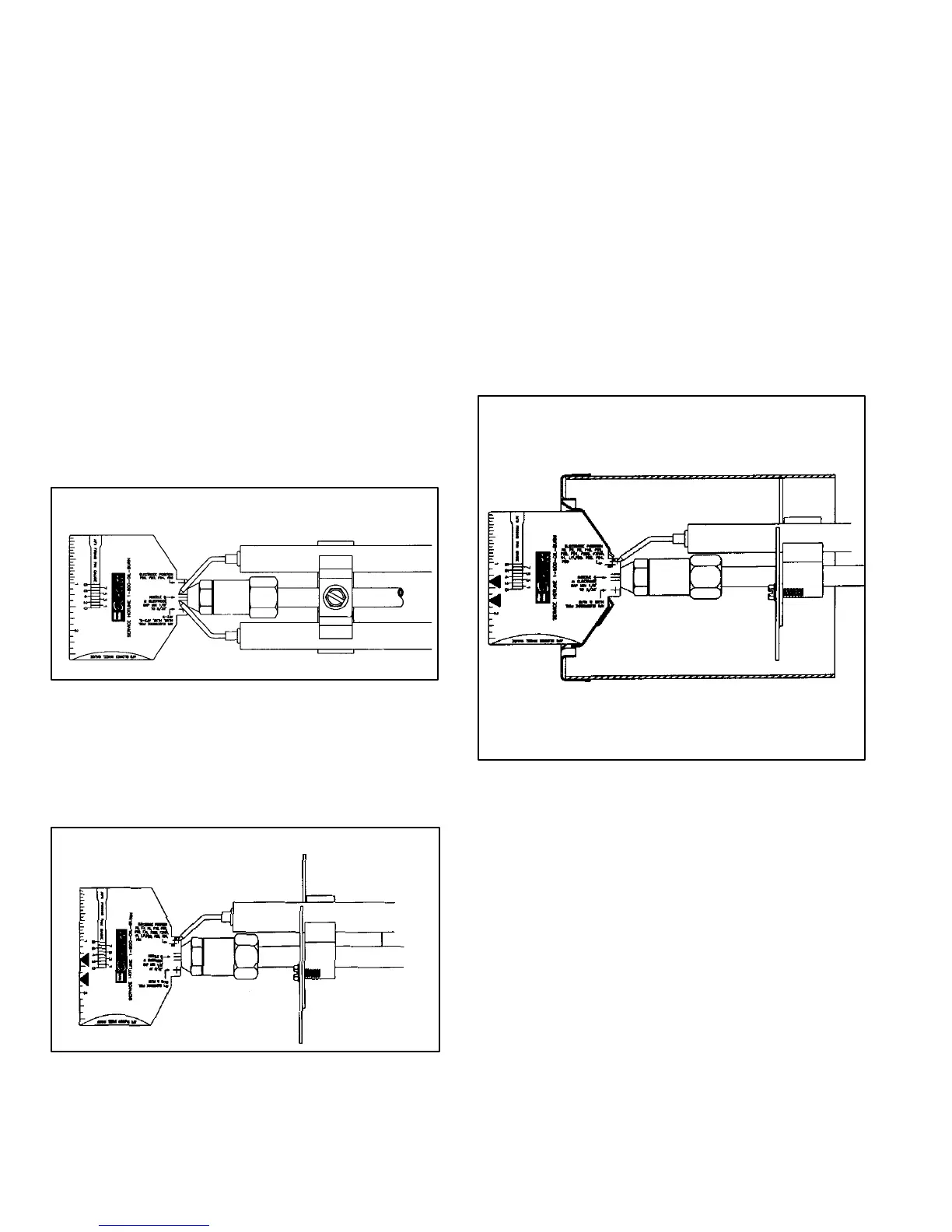

To position the electrode tips beyond the face of the nozzle

and above the center line, position the gauge as shown in

figure 26. Align the center mark with the nozzle and adjust

the electrodes to the AC cross marks.

FIGURE 26

AFII ELECTRODE POSITIONING

To check that the nozzle is approximately centered with

the head inside diameter, align the center mark of the

gauge with the center of the nozzle orifice, as shown in

figure 27, and move the gauge from side to side at sev

eral points. Be careful not to scratch the nozzle sur

face.

The Z" or zero dimension is important because it locates the

nozzle for the precise relationship with the combustion head.

To set the Z" dimension, position the gauge as shown in fig

ure 27 and loosen the nozzle line electrode assembly so that

it can be moved forward or backward in the air tube until the

nozzle becomes flush against the gauge. Tighten the nozzle

line escutcheon plate screw (shown in figure 9) to lock this

Z" dimension securely.

FIGURE 27

AFII NOZZLE CENTERING

C−Pressure Check

On −1 through −4 units use either the gauge port or

nozzle port to check operating pressure. On −5 units use

the nozzle port (−5 unit pumps are not equipped with

gauge port). The pump is factory set at 100 psig (689.5

kPa) for the O23Q2−70 and 140 psig (965.3 kPa) for all

other O23, OHR23, and OF23 units but is adjustable (see fig

ure 28). Never operate the pump in excess of 10 psig (69

kPa) above set point. Average nozzle cutoff pressure is

80 psig (551.6 kPa). To check the cutoff pressure install

a pressure gauge in nozzle port. For −5 units use the

same gauge used for operating pressure. Run the burn

Loading...

Loading...