Page 8

The counterclockwise orbiting scroll draws gas into the outer

crescent shaped gas pocket created by the two scrolls as

illustrated in Figure 3, detail A. The centrifugal action of the

orbiting scroll seals off the flanks of the scrolls as illustrate din

Figure 3, detail B. As the orbiting motion continues, the gas is

forced toward the center of the scroll and the gas pocket

becomes compressed as illustrated in Figure 3, detail C.

When the compressed gas reaches the center, it is

discharged vertically into a chamber and discharge port in the

top of the compressor as illustrate in Figure 5. The discharge

pressure forcing down on the top scroll helps seal off the

upper and lower edges (tips) of the scrolls as illustrated in

Figure 5. During a single orbit, several pockets of gas are

compressed simultaneously providing smooth continuous

compression.

The scroll compressor is tolerant to the effects of liquid

return. If liquid enters the scrolls, the orbiting scroll is allowed

to separate from the stationary scroll. The liquid is worked

toward the center of the scroll and is discharged. If the

compressor is replaced, conventional Lennox cleanup

practices must be used.

Due to its efficiency, the scroll compressor is capable of

drawing a much deeper vacuum than reciprocating

compressors. Deep vacuum operation can cause

internal fusite arcing resulting in damaged internal parts

and will result in compressor failure. Never use a scroll

compressor for evacuating or to pump system into a

vacuum. This type of damage can be detected and will

result in denial of warranty claims.

The scroll compressor is quieter than a reciprocating

compressor, however, the two compressors have much

different sound characteristics. The sounds made by a scroll

compressor do not affect system reliability, performance, or

indicate damage.

See compressor nameplate or ELECTRICAL DATA for

compressor specifications.

General Information7

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

Operating Gauge Set and Service Valves8

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

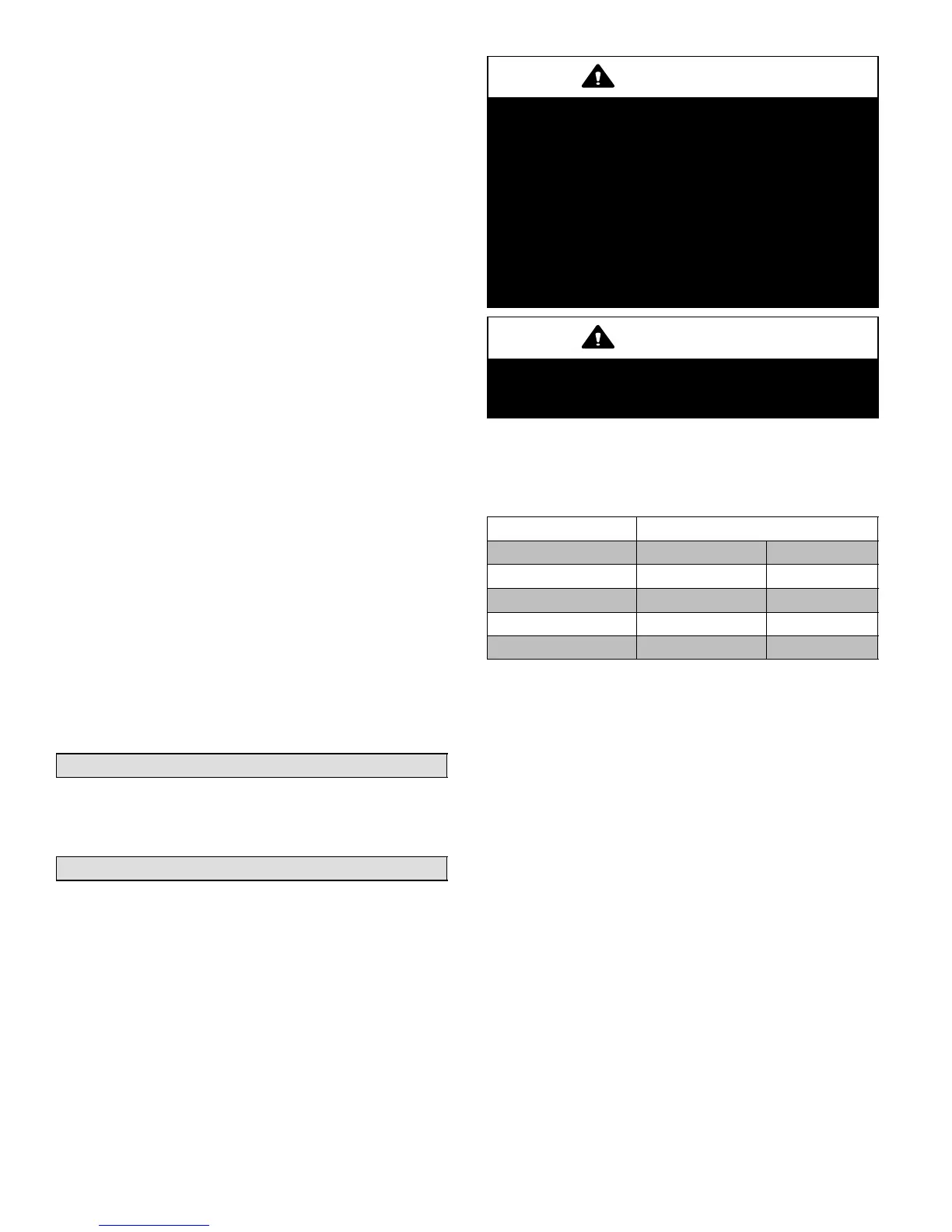

TORQUE REQUIREMENTS

When servicing or repairing heating, ventilating, and air

conditioning components, ensure the fasteners are

appropriately tightened. Table 1 lists torque values for

fasteners.

IMPORTANT

Only use Allen wrenches of sufficient hardness (50Rc −

Rockwell Harness Scale minimum). Fully insert the

wrench into the valve stem recess.

Service valve stems are factory−torqued (from 9 ft−lbs for

small valves, to 25 ft−lbs for large valves) to prevent

refrigerant loss during shipping and handling. Using an

Allen wrench rated at less than 50Rc risks rounding or

breaking off the wrench, or stripping the valve stem

recess.

See the Lennox Service and Application Notes #C−08−1

for further details and information.

IMPORTANT

To prevent stripping of the various caps used, the

appropriately sized wrench should be used and fitted

snugly over the cap before tightening.

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. Table 1 provides

torque values for fasteners.

Table 1. Torque Requirements

Parts Recommended Torque

Service valve cap 8 ft.− lb. 11 NM

Sheet metal screws 16 in.− lb. 2 NM

Machine screws #10 28 in.− lb. 3 NM

Compressor bolts 90 in.− lb. 10 NM

Gauge port seal cap 8 ft.− lb. 11 NM

USING MANIFOLD GAUGE SET

When checking the system charge, only use a manifold

gauge set that features low loss anti−blow back fittings.

Manifold gauge set used with HFC−410A refrigerant

systems must be capable of handling the higher system

operating pressures. The gauges should be rated for use

with pressures of 0 − 800 psig on the high side and a low

side of 30" vacuum to 250 psig with dampened speed to

500 psi. Gauge hoses must be rated for use at up to 800

psig of pressure with a 4000 psig burst rating.

OPERATING SERVICE VALVES

The liquid and vapor line service valves are used for

removing refrigerant, flushing, leak testing, evacuating,

checking charge and charging.

Each valve is equipped with a service port which has a

factory−installed valve stem. Figure 6 provides information

on how to access and operating both angle and ball service

valves.

Loading...

Loading...