Page 6

Unit Components

CONTROL BOX

TSA*S4 units are not equipped with a 24V transformer. All

24 VAC controls are powered by the indoor unit. Refer to

wiring diagram.

Electrical openings are provided under the control box

cover. Field thermostat wiring is made to color-coded

pigtail connections.

COMPRESSOR CONTACTOR K1

The compressor is energized by a contactor located in the

control box as illustated on Page 4. One or three−pole

contactors are used in this model. K1 is energized by the

indoor thermostat terminal Y1 (24V) when thermostat

demand is present.

CONDENSER FAN MOTOR B4 AND CAPACITOR C1

This model use a one−phase PSC fan motors which require a

run capacitor C1 located in the control box. Ratings for

C1 will be on fan motor nameplate. In all units, the

condenser fan is controlled by the compressor

contactor.

ELECTRICAL DATA tables in this manual show

specifications for condenser fans used in this model.

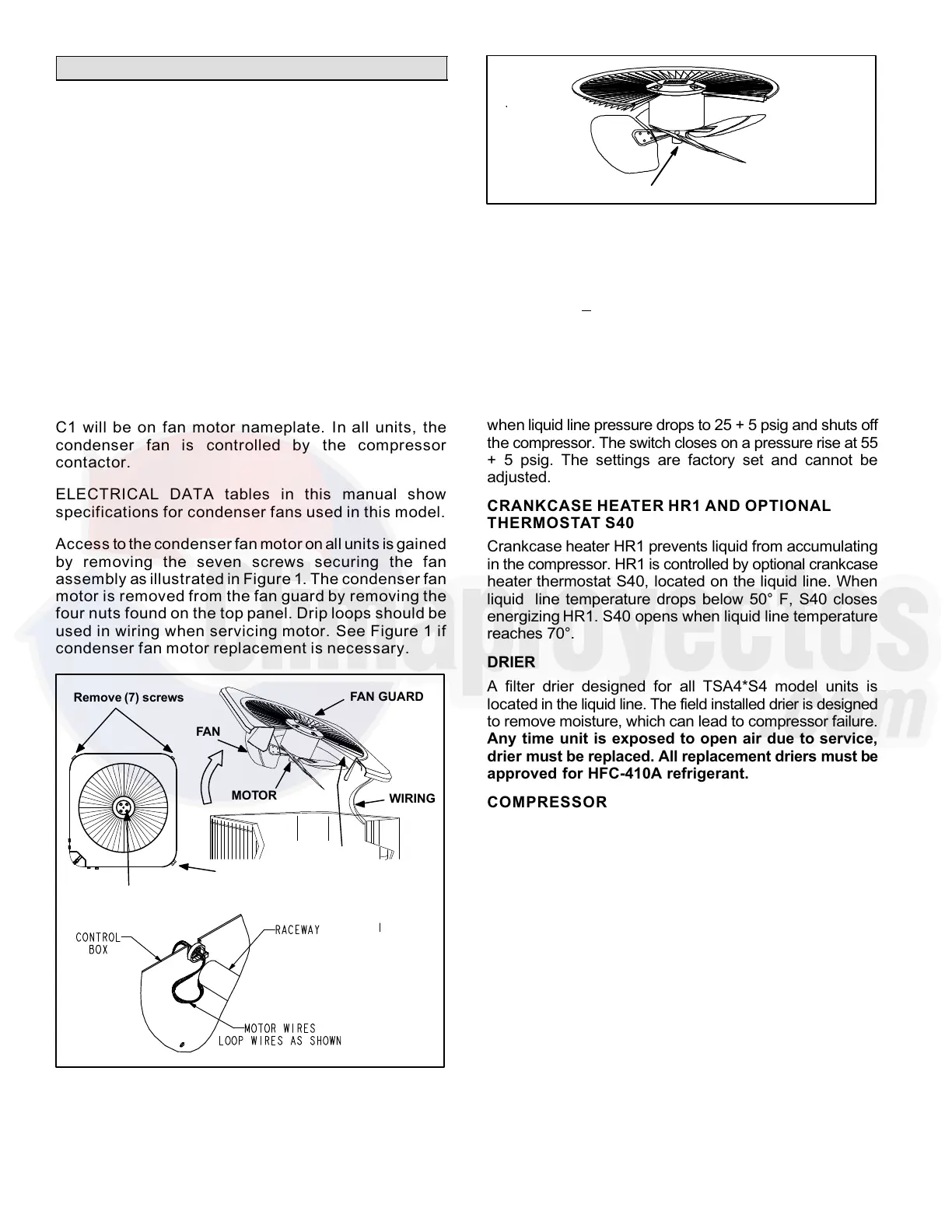

Access to the condenser fan motor on all units is gained

by removing the seven screws securing the fan

assembly as illustrated in Figure 1. The condenser fan

motor is removed from the fan guard by removing the

four nuts found on the top panel. Drip loops should be

used in wiring when servicing motor. See Figure 1 if

condenser fan motor replacement is necessary.

FAN

Remove (7) screws

REMOVE (7) SCREWS

SECURING FAN GUARD.

REMOVE FAN GUARD/FAN AS-

SEMBLY.

MOTOR

FAN GUARD

WIRING

RACEWAY

Remove (4) nuts

Figure 1. Condenser Fan Motor and Compressor

Access

ALIGN FAN HUB FLUSH WITH END OF SHAFT

Figure 2. Fan Hub Alignment.

HIGH PRESSURE SWITCH S4

The manual−reset high pressure switch is located in the

liquid line. When liquid line pressure exceeds the factory

setting of 590 + 10 psi, the switch opens and shuts off the

compressor.

LOSS OF CHARGE SWITCH S24 (FIELD

INSTALLED OPTION)

The loss of charge switch is N.C. auto re−set and located

on the liquid line of the compressor. The switch opens

when liquid line pressure drops to 25 + 5 psig and shuts off

the compressor. The switch closes on a pressure rise at 55

+ 5 psig. The settings are factory set and cannot be

adjusted.

CRANKCASE HEATER HR1 AND OPTIONAL

THERMOSTAT S40

Crankcase heater HR1 prevents liquid from accumulating

in the compressor. HR1 is controlled by optional crankcase

heater thermostat S40, located on the liquid line. When

liquid line temperature drops below 50° F, S40 closes

energizing HR1. S40 opens when liquid line temperature

reaches 70°.

DRIER

A filter drier designed for all TSA4*S4 model units is

located in the liquid line. The field installed drier is designed

to remove moisture, which can lead to compressor failure.

Any time unit is exposed to open air due to service,

drier must be replaced. All replacement driers must be

approved for HFC−410A refrigerant.

COMPRESSOR

All TSA*S4 units utilize a scroll compressor. The scroll

compressor design is simple, efficient and requires few

moving parts. A cutaway diagram of the scroll compressor is

illustrated in Figure 3. The scrolls are located in the top of the

compressor can and the motor is located just below. The oil

level is immediately below the motor.

The scroll is a simple compression concept centered around

the unique spiral shape of the scroll and its inherent

properties. Two identical scrolls are mated together forming

concentric spiral shapes as illustrated in Figure 4. One scroll

remains stationary, while the other is allowed to "orbit" (figure

5). Note that the orbiting scroll does not rotate or turn but

merely orbits the stationary scroll.

NOTE − During operation, the head of a scroll compressor

may be hot since it is in constant contact with discharge gas.

Loading...

Loading...