Page 8

FIGURE 9

Remove

screws

Remove

screws

FIGURE 10

E − Discharge Line Thermostat (S5)

The discharge line thermostat is NC, auto re−set and located

on the discharge line of the compressor. The switch opens

when discharge line temperatures exceeds the factory set-

ting of 220° +

5° F and shuts down the compressor.

F − High Pressure Switch (S4)

XC14 units are equipped with a high pressure switch that is

located in the liquid line of the compressor. The switch

(SPST, manual reset, normally closed) removes power from

the compressor contactor control circuit when discharge

pressure rises above factory setting at 590 +

10 psi.

G − Crankcase Heater (HR1) &

Thermostat (S40) 4 and 5 ton only

XC14−048 and −060 units are equipped with a 70 watt belly

band type crankcase heater. HR1 prevents liquid from accu-

mulating in the compressor. HR1 is controlled by a thermo-

stat located on the liquid line. When liquid line temperature

drops below 50° F the thermostat closes energizing HR1.

The thermostat will open, de−energizing HR1 once liquid line

temperature reaches 70° F.

H − Loss of Charge Switch (option) (S24)

The loss of charge switch is NC, auto re−set and located on

the suction line of the compressor.The switch opens when

suction line pressure drops to 25psi +

5 (shutting down the

compressor) and will close when suction line pressure rises

to 55psi +

5.

III − REFRIGERANT SYSTEM

A − Plumbing

Field refrigerant piping consists of liquid and suction lines

from the condensing unit (sweat connections) to the indoor

evaporator coil (sweat connections). Use Lennox L15

(sweat) series line sets as shown in table 1.

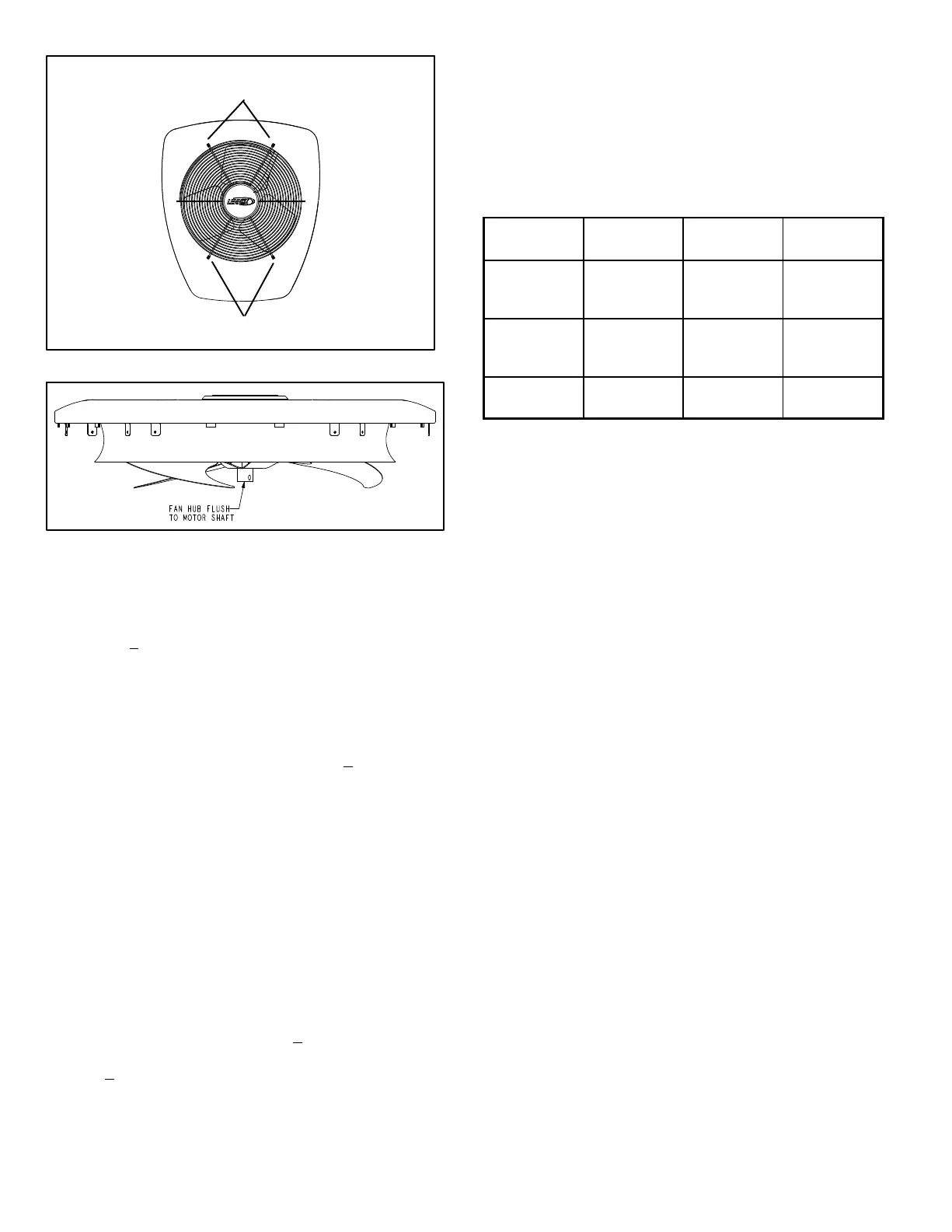

TABLE 1

Unit

Liquid

Line

Suction

Line

L15 Line

Sets

018, −024,

−030,

3/8 in.

(10 mm)

3/4 in.

(19 mm)

L15−41

20 ft. − 50 ft.

(6 m − 15 m)

−036, −042,

−048

3/8 in.

(10 mm)

7/8 in.

(22 mm)

L15−65

30 ft. − 50 ft.

(9 m − 15 m)

−060

3/8 in.

(10 mm)

1−1/8 in.

(29 mm)

Field

Fabricated

The liquid line and vapor line service valves (figures 11 and

12) and gauge ports are accessible from the outside of the

unit. Use the service ports for leak testing, evacuating,

charging and checking charge.

Each valve is equipped with a service port which has a facto-

ry−installed Schrader valve. A service port cap protects the

Schrader valve from contamination and serves as the pri-

mary leak seal. Service valves are not rebuildable. If a valve

has failed, you must replace it.

To Access Schrader Port:

1 − Remove service port cap with an adjustable wrench.

2 − Connect gauge to the service port.

3 − When testing is complete, replace service port cap. Tight-

en finger tight, then an additional 1/6 turn.

To Open Service Valve:

1 − Remove the stem cap with an adjustable wrench.

2 − Using the adjustable wrench to keep the valve station-

ary, use a service wrench with a hex−head extension to

back the stem out counterclockwise as far as it will go.

NOTE − Use a 3/16" hex head extension for 3/8" line

sizes or a 5/16" extension for large line sizes.

3 − Replace the stem cap. Tighten finger tight, then tighten

an additional 1/6 turn.

Loading...

Loading...