Page 6

B − Compressor (B1)

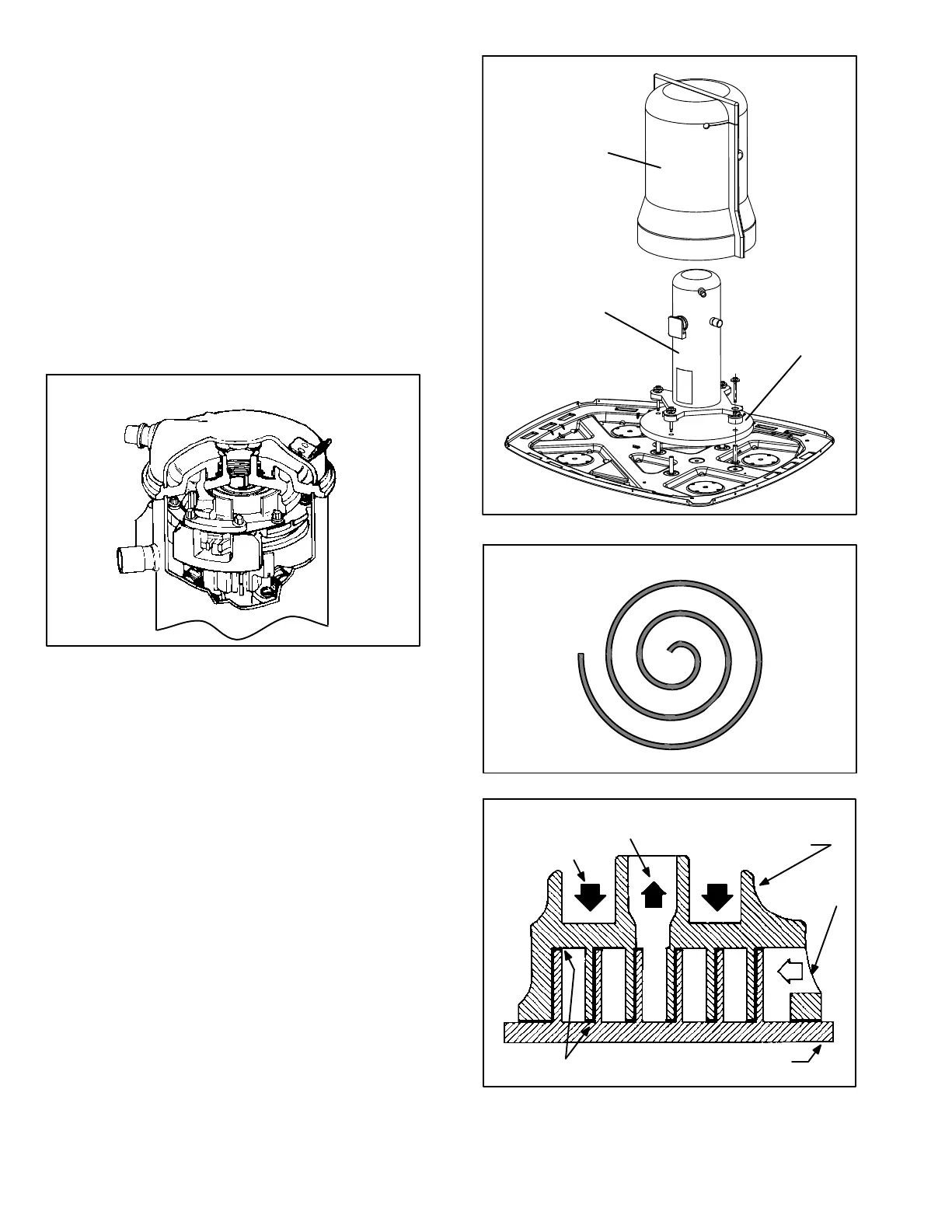

The scroll compressor used in all XC14 model units, is de-

signed for use with R410A refrigerant and operation at high

pressures. Compressors are shipped from the factory

charged with 3MA (32MMMA) P.O.E. oil. All XC14 compres-

sors are equipped with a factory installed sound cover made

of polyethylene containing a 2 inch thick batt of fiberglass in-

sulation. See figure 5.

See ELECTRICAL DATA table at the front of this manual or

compressor nameplate for compressor specifications.

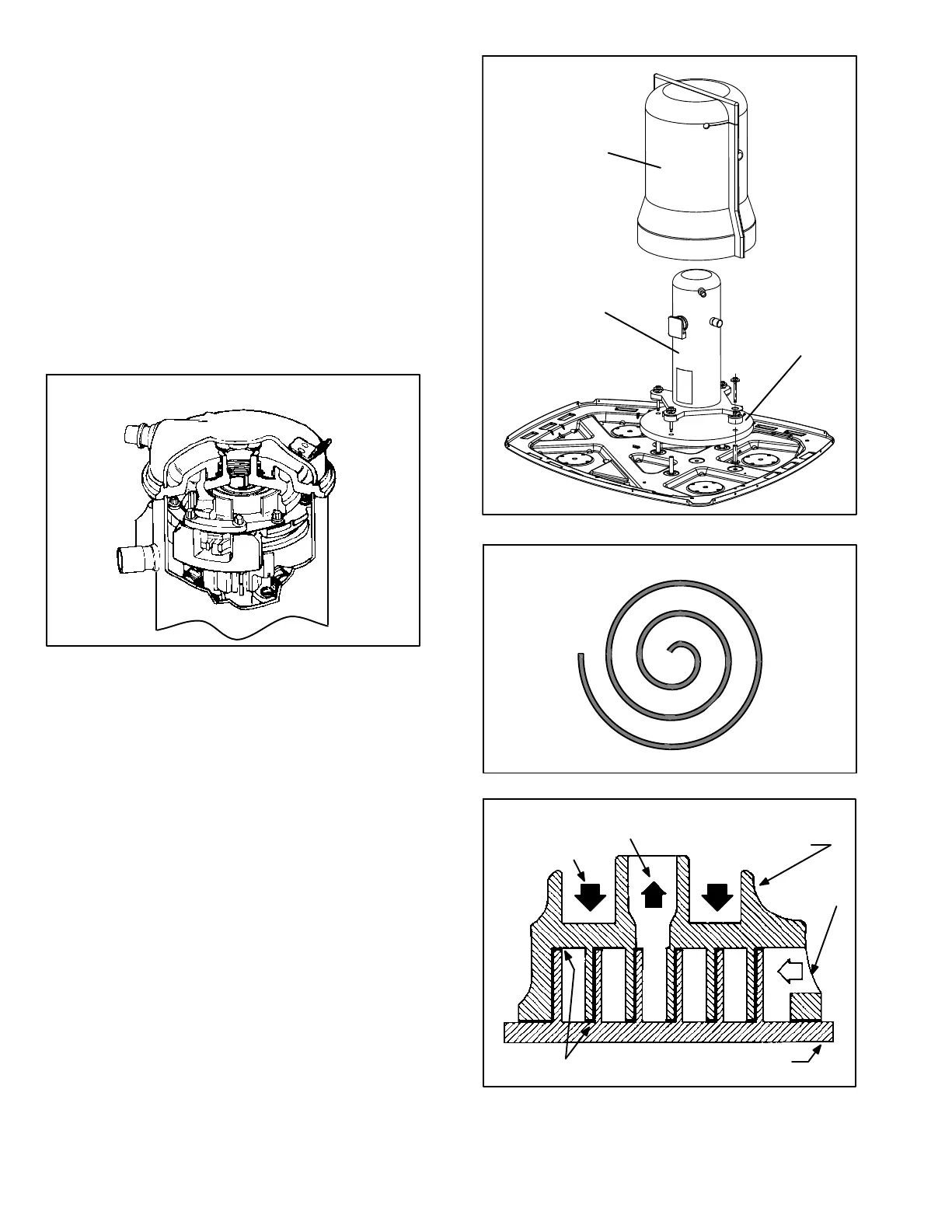

The scroll compressor design is simple, efficient and requires

few moving parts. A cutaway diagram of the scroll compressor

is shown in figure 4. The scrolls are located in the top of the

compressor can and the motor is located just below. The oil lev-

el is immediately below the motor.

FIGURE 4

SCROLL COMPRESSOR

DISCHARGE

SUCTION

The scroll is a simple compression concept centered around

the unique spiral shape of the scroll and its inherent properties.

Figure 6 shows the basic scroll form. Two identical scrolls are

mated together forming concentric spiral shapes (figure 7). One

scroll remains stationary, while the other is allowed to "orbit" (fig-

ure 8). Note that the orbiting scroll does not rotate or turn but

merely orbits the stationary scroll.

NOTE − During operation, the head of a scroll compressor may

be hot since it is in constant contact with discharge gas.

FIGURE 5

SOUND COVER

COMPRESSOR

SOUND PAD

FIGURE 6

SCROLL FORM

FIGURE 7

STATIONARY SCROLL

ORBITING SCROLL

DISCHARGE

SUCTION

CROSS−SECTION OF SCROLLS

TIPS SEALED BY

DISCHARGE PRESSURE

DISCHARGE

PRESSURE

Loading...

Loading...