Troubleshooting and fault elimination8

66

Lenze ¯ MA 12.0014 ¯ 5.1

8 Troubleshooting and fault elimination

If any malfunctions should occur during operation of the drive system, please check the

possible causes using the following table. If the fault cannot be eliminated by one of the

listed measures, please contact the Lenze Service.

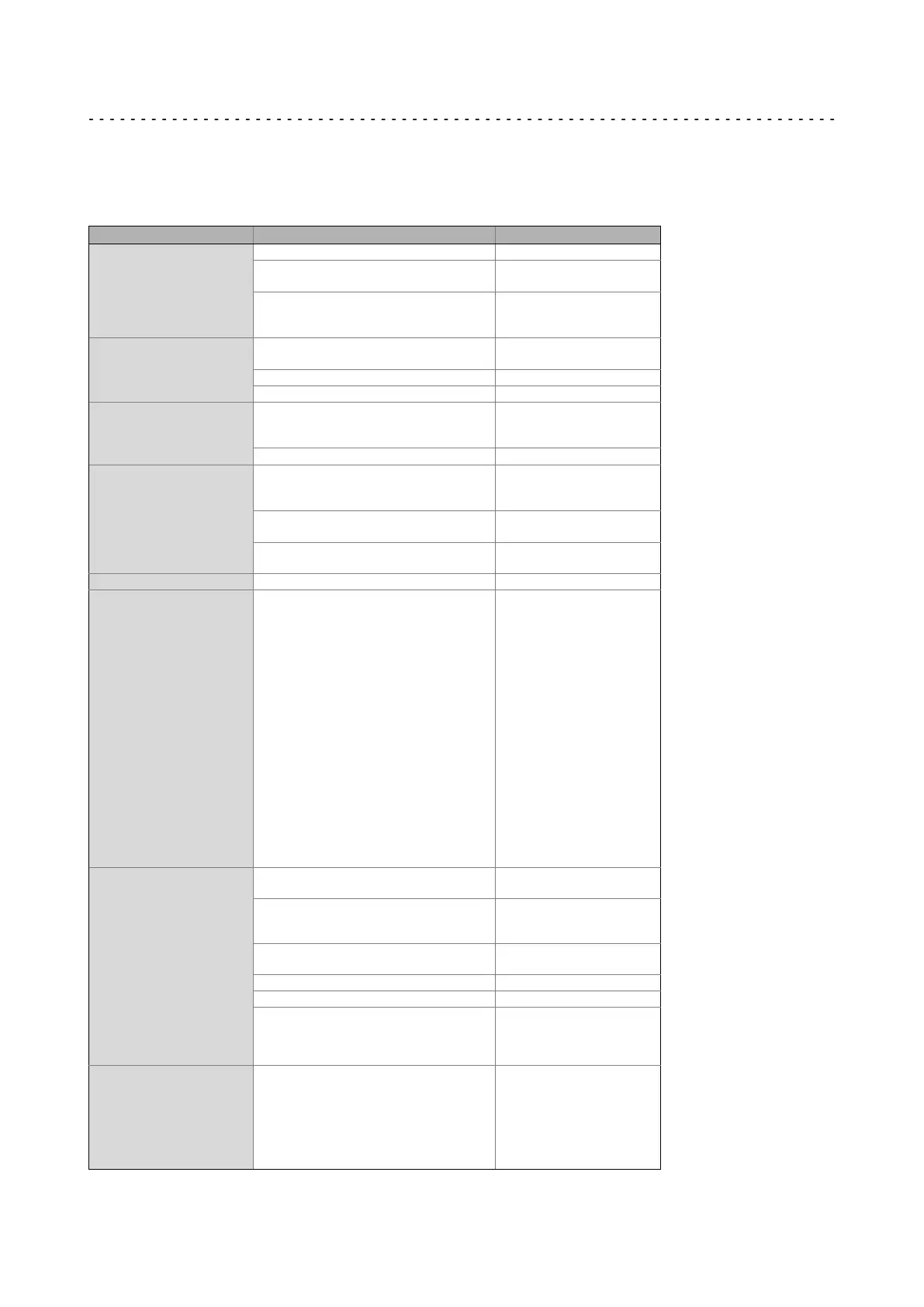

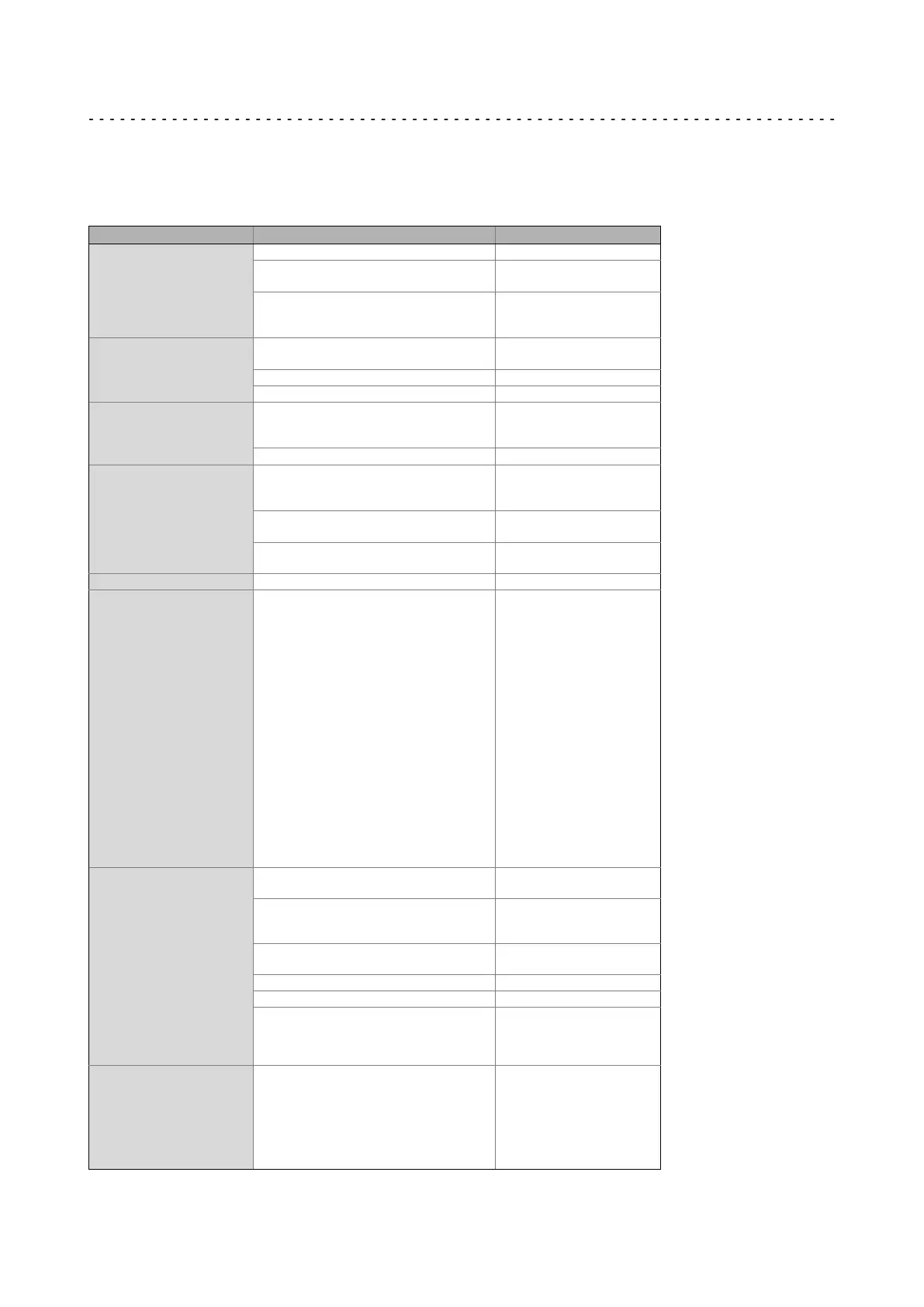

Fault Possible cause Remedy

Drive is not running

Voltage supply interrupted Check connection

Faulty electrical connection Check that supply voltage

matches nameplate data

Excessive load Reduce load

Check drive−machine

assignment

Motor is running, but

gearbox is not running

Coupling components are missing or

defective

Check mounting

Gearbox is defective Inform Lenze Service

Clutch disengaged Engage the clutch

Unusual running noises

Overload Reduce load

Check drive−machine

assignment

Damage to the gearbox or motor Inform Lenze Service

Excessive temperature

Overload Reduce load

Check drive−machine

assignment

Inadequate heat dissipation Improve cooling air flow

Clean gearbox / motor

Lack of lubricant Top up lubricant according to

regulations

Vibrations, noise Loose fixing elements Tighten fixing elements

Shrink disc connection is

spinning

¯ Correct screw tightening torque has not

been reached

– Insufficient number of passes, not all

screws are tightened correctly.

¯ Machine shaft and hollow shaft bore

not sufficiently degreased

¯ Wrong component part dimensions

– Fits, roughnesses

¯ Yield point of machine shaft material is

too low

– Re > 300 N/mm

2

required

¯ Friction factors are too low

– Coefficients of friction m ³ 0.15

required

¯ The shrink disc itself has been

degreased so that the screws and the

bevels are dry. Due to incorrect friction

factors, the shrink disc cannot be

tightened correctly.

Specifications for assembly,

dimensions and material not

observed

Oil is leaking

Wrong oil level for the applied mounting

position

Check mounting position

(see nameplate) and oil level

Initial insignificant leakage at the shaft

sealing ring

Optimum sealing conditions

only develop after the run−in

period

Overpressure due to lacking ventilation Install ventilation according

to the mounting position

Overpressure due to polluted ventilation Clean ventilation

Worn−out shaft sealing rings Change shaft sealing rings

Cover / flange screws are loose Check that the fixing screws

are tightly fastened.

Continue to monitor the

gearbox

Oil discharge at the gearbox

ventilation unit

Incorrect oil level for the mounting position

applied and/or incorrect position of

ventilation unit

Mounting position (see

nameplate)

Check oil level^ 59

Check position of ventilation

unit ^ 50

Use oil compensation

reservoir

Loading...

Loading...