Electrical installation

Important notes

EMC-compliant wiring

5

31

BA33.0001 EN 2.0

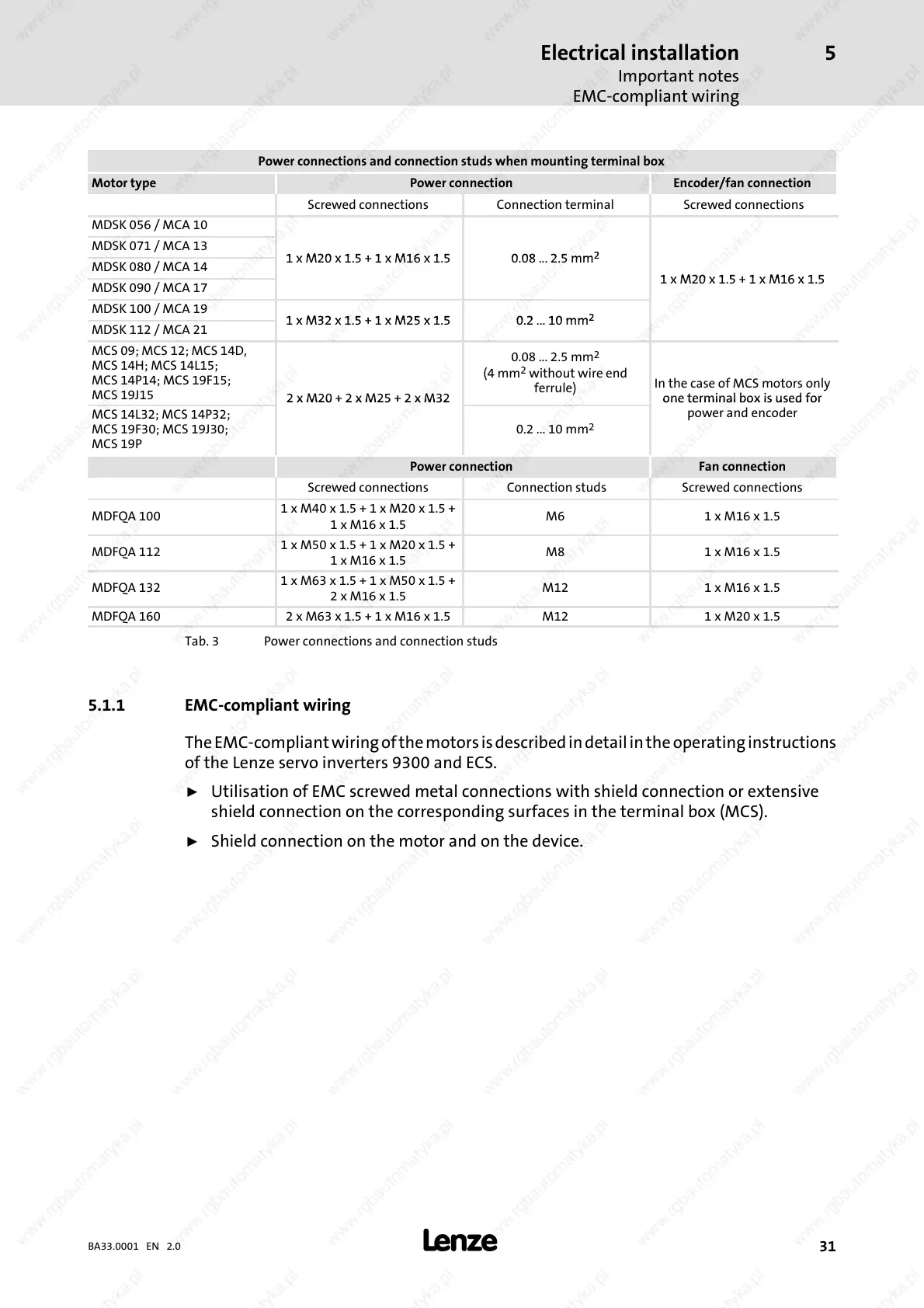

Power connections and connection studs when mounting terminal box

Motor type Power connection Encoder/fan connection

Screwed connections Connection terminal Screwed connections

MDSK 056 / MCA 10

MDSK 071 / MCA 13

MDSK 080 / MCA 14

1xM20x1.5+1xM16x1.5 0.08 ... 2.5 mm

2

MDSK 090 / MCA 17

1xM20x1.5+1xM16x1.5

MDSK 100 / MCA 19

MDSK 112 / MCA 21

1xM32x1.5+1xM25x1.5 0.2 ... 10 mm

2

MCS 09; MCS 12; MCS 14D,

MCS 14H; MCS 14L15;

MCS 14P14; MCS 19F15;

MCS 19J15

2xM20+2xM25+2xM32

0.08 ... 2.5 mm

2

(4 mm

2

without wire end

ferrule)

InthecaseofMCSmotorsonly

one terminal box is used

or

MCS 14L32; MCS 14P32;

MCS 19F30; MCS 19J30;

MCS 19P

0.2 ... 10 mm

2

power and encoder

Power connection Fan connection

Screwed connections Connection studs Screwed connections

MDFQA 100

1xM40x1.5+1xM20x1.5+

1xM16x1.5

M6 1xM16x1.5

MDFQA 112

1xM50x1.5+1xM20x1.5+

1xM16x1.5

M8 1xM16x1.5

MDFQA 132

1xM63x1.5+1xM50x1.5+

2xM16x1.5

M12 1xM16x1.5

MDFQA 160 2xM63x1.5+1xM16x1.5 M12 1xM20x1.5

Tab. 3 Power connections and connection studs

5.1.1 EMC-compliant wiring

TheEMC-compliantwiring ofthemotors is described in detailin the operating instructions

of the Lenze servo inverters 9300 and ECS.

ƒ

Utilisation of EMC screwed metal connections with shield connection or extensive

shield connection on the corresponding sur faces in the terminal box (MCS).

ƒ

Shield connection on the motor and on the device.

Loading...

Loading...