LGE Internal Use OnlyCopyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 12 -

6.3. Adjustment of RGB

(1) Required Equipments

- Remote controller for adjustment

- MSPG-925FS Pattern Generator

(Which has XGA [1024*768] 60Hz 8 Color bar 100%

pattern shown in Fig. 1)

(2) Method of Auto RGB Color Balance

1) Input the PC 1024x768@60Hz 100% Color Bar (MSPG-

925FS model:60, pattern:65) signal into RGB.

(Using D-sub to D-sub cable)

2) Set the PSM to Dynamic mode in Picture menu.

3) Press the IN-START key on R/C for adjustment

4) Press the

G(Vol.+) key operate To set , then it becomes

automatically.

5) Auto-RGB OK means adjustment is completed.

* Before White-balance, the AV ADC should be done.

7. White Balance

* Test Equipment

Color Analyzer (CA-210/CH.9)

-> When you adjust LCD color temperature, on Color

analyzer (CA-210), you should use Channel 9 which is

Matrix compensated (White, Red, Green, Blue revised) by

CS-1000 and adjust in accordance with White balance

adjustment coordinate which is specified on the next.

* Color temperature standards according to CSM and Module

Cool : 11,000k

Medium : 9,300k

Warm : 6,500k

* White balance adjustment coordinate and color temperature

- PC (for communication through RS-232C)

-> UART Baud rate : 115200 bps

- Luminance Y AV : upper 150 cd/m

2

(Typ : 350 cd/m

2

)

-> Applying to Cool, Medium, Warm mode

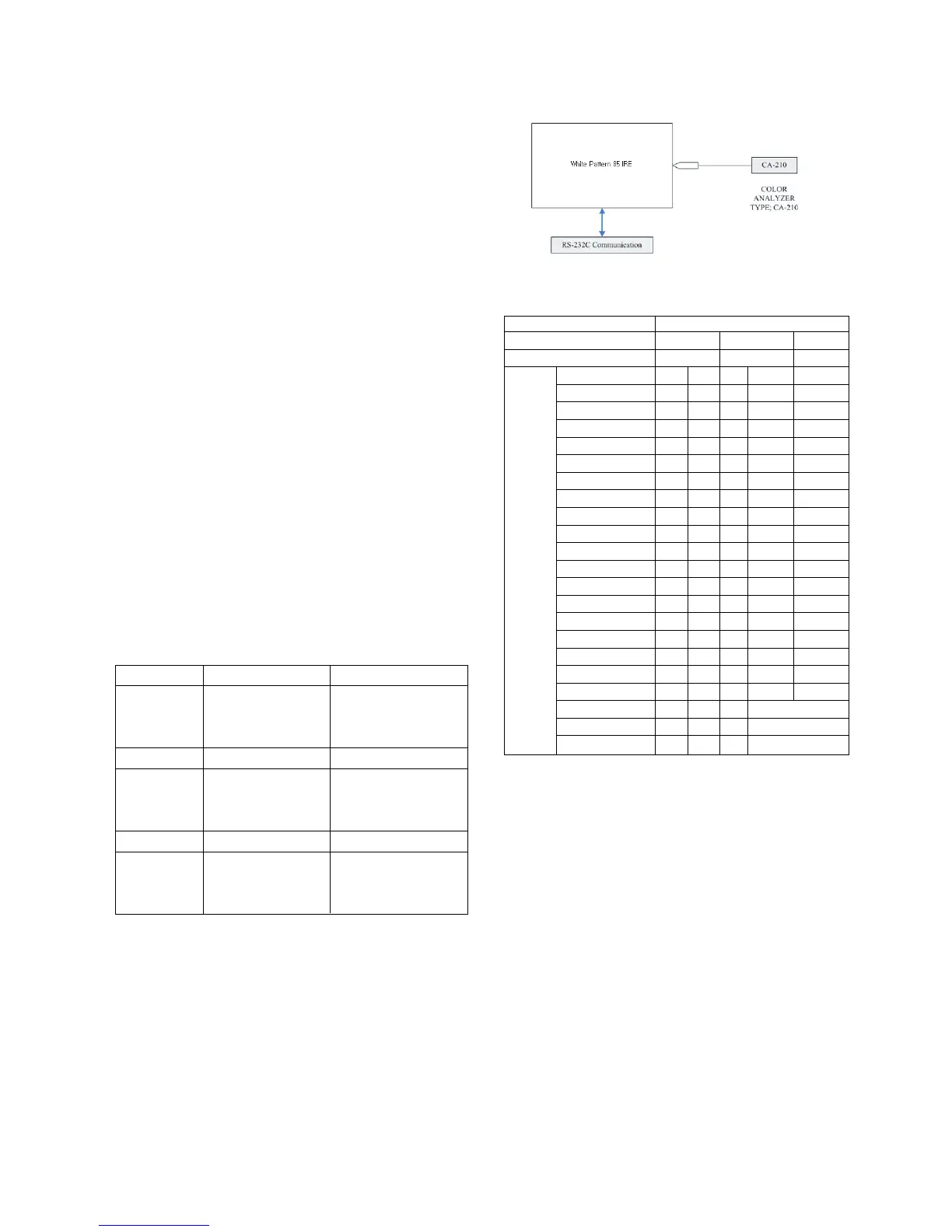

* Connecting picture of the measuring instrument (On

Automatic control)

Inside PATTERN is used when W/B is controlled. Connect to

auto controller or push control R/C IN-START

-> Enter the mode of White-Balance, the pattern will come

out.

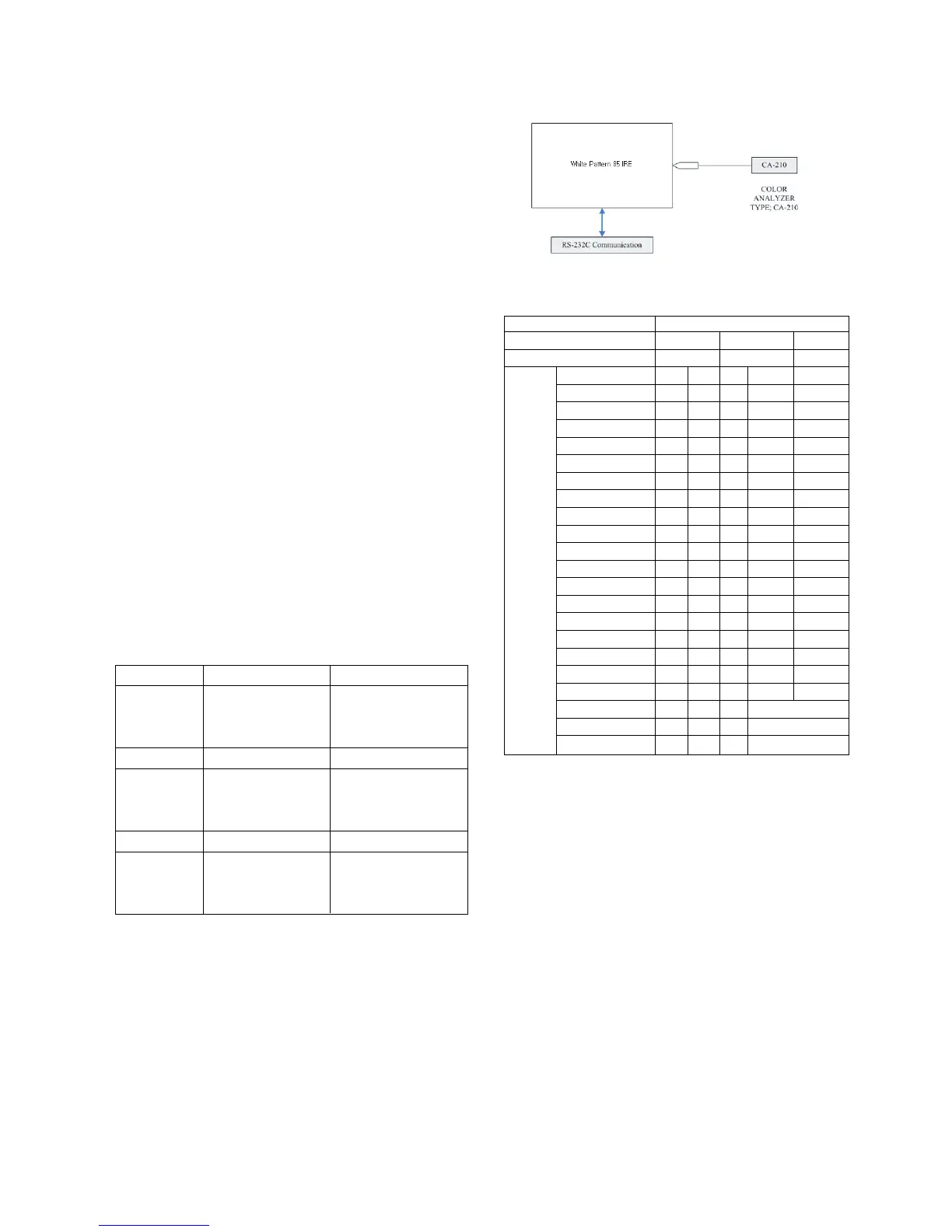

* Auto adjustment Map (RS-232C)

* Auto-control interface and directions

1) Adjust in the place where the influx of light like floodlight

around is blocked. (illumination is less than 10ux).

2) Adhere closely the Color Analyzer ( CA-210 ) to the

module less than 10cm distance, keep it with the surface

of the Module and Color Analyzer’s Prove

vertically.(80~100°).

3) Aging time

- After aging start, keep the power on (no suspension of

power supply) and heat-run over 15 minutes.

- Using ‘no signal’ or ‘full white pattern’ or the others,

check the back light on.

Cool CS-1000 CA-210(CH 9)

x 0.276 0.276±0.002

y 0.283 0.283±0.002

∆uv 0.000 0.000

Medium CS-1000 CA-210(CH 9)

x 0.285 0.285±0.002

y 0.293 0.293±0.002

∆uv 0.000 0.000

Warm CS-1000 CA-210(CH 9)

x 0.313 0.313±0.002

y 0.329 0.329±0.002

∆uv 0.004 0.004

<Fig. 2> Connecting picture (On Automatic Control)

Type LD74A

Baud Rate Data bit Stop bit Parity

115200 8 1 None

Protocol Index Cmd 1 Cmd 2 Data Min Value Max Value

Setting R-Gain_Normal j a 00(00) 128(80)

G-Gain_Normal j b 00(00) 128(80)

B-Gain_Normal j c 00(00) 128(80)

R-Gain_Warm j d 00(00) 128(80)

G-Gain_Warm j e 00(00) 128(80)

B-Gain_Warm j f 00(00) 128(80)

R-Gain_Cool j g 00(00) 128(80)

G-Gain_Cool j h 00(00) 128(80)

B-Gain_Cool j i 00(00) 128(80)

R-Offset_Normal l j 00(00) 128(80)

G-Offset_Normal l k 00(00) 128(80)

B-Offset_Normal l l 00(00) 128(80)

R-Offset_Warm l m 00(00) 128(80)

G-Offset_Warm l n 00(00) 128(80)

B-Offset_Warm l o 00(00) 128(80)

R-Offset_Cool l p 00(00) 128(80)

G-Offset_Cool l q 00(00) 128(80)

B-Offset_Cool l r 00(00) 128(80)

Internal Pattern Signal w b 00 W/B adjustment Start

Internal Pattern Signal w b 10 Internal Pattern use

Internal Pattern Signal w b ff W/B adjustment end

Loading...

Loading...