- 12 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

4. Total Assembly line process

4.1. Adjustment Preparation

■ W/B Equipment condition

CA210 : CH14, Test signal : Inner pattern (80IRE) – in case of

LED back light

■ Above 5 minutes H/run in the inner pattern. (“power on” key of

adjust remote control)

► The spec of color temperature and coordinate

Model Mode Color Temp Color coordinate Remark

All

Cool (C50) 13,000k

x = 0.271 (±0.002)

y = 0.270 (±0.002)

※ Test signal

- Inner pattern for W/B adjust

- External white pattern

(80IRE, 204gray)

Medium (0) 9,300k

x = 0.286 (±0.002)

y = 0.289 (±0.002)

Warm (W50) 6,500k

x = 0.313 (±0.002)

y = 0.329 (±0.002)

► CA210 : CH 14, Test signal : Inner pattern (80IRE)

- Standard color coordinate and temperature using CA-1000 (by

H/R time)

▪ Normal line

model: (normal line)LN5xxx, LA6xxx, LA7xxx, LA8xxx

H/R Time(Min)

Cool Medium Warm

x y x x y x

271 270 286 289 313 329

1 0-2 283 287 298 306 322 342

2 3-5 282 285 297 304 321 340

3 6-9 281 284 296 303 320 339

4 10-19 279 281 294 300 318 336

5 20-35 277 277 292 296 316 332

6 36-49 275 274 290 293 314 329

7 50-79 273 272 288 291 312 327

8 80-119 272 271 287 290 311 326

9 Over 120 271 270 286 289 310 325

▪ Aging chamber line

model: (aging chamber)LN5xxx, LA6xxx, LA7xxx, LA8xxx

H/R Time(Min)

Cool Medium Warm

x y x x y x

271 270 286 289 313 329

1 0-5 282 285 297 304 321 340

2 6-10 278 280 293 299 317 335

3 11-20 275 275 290 294 314 330

4 21-30 272 272 287 291 311 327

5 31-40 269 269 284 288 308 324

6 41-50 268 267 283 286 307 322

7 51-80 267 266 282 285 306 321

8 81-119 266 264 281 283 305 319

9 Over 120 265 263 280 282 304 318

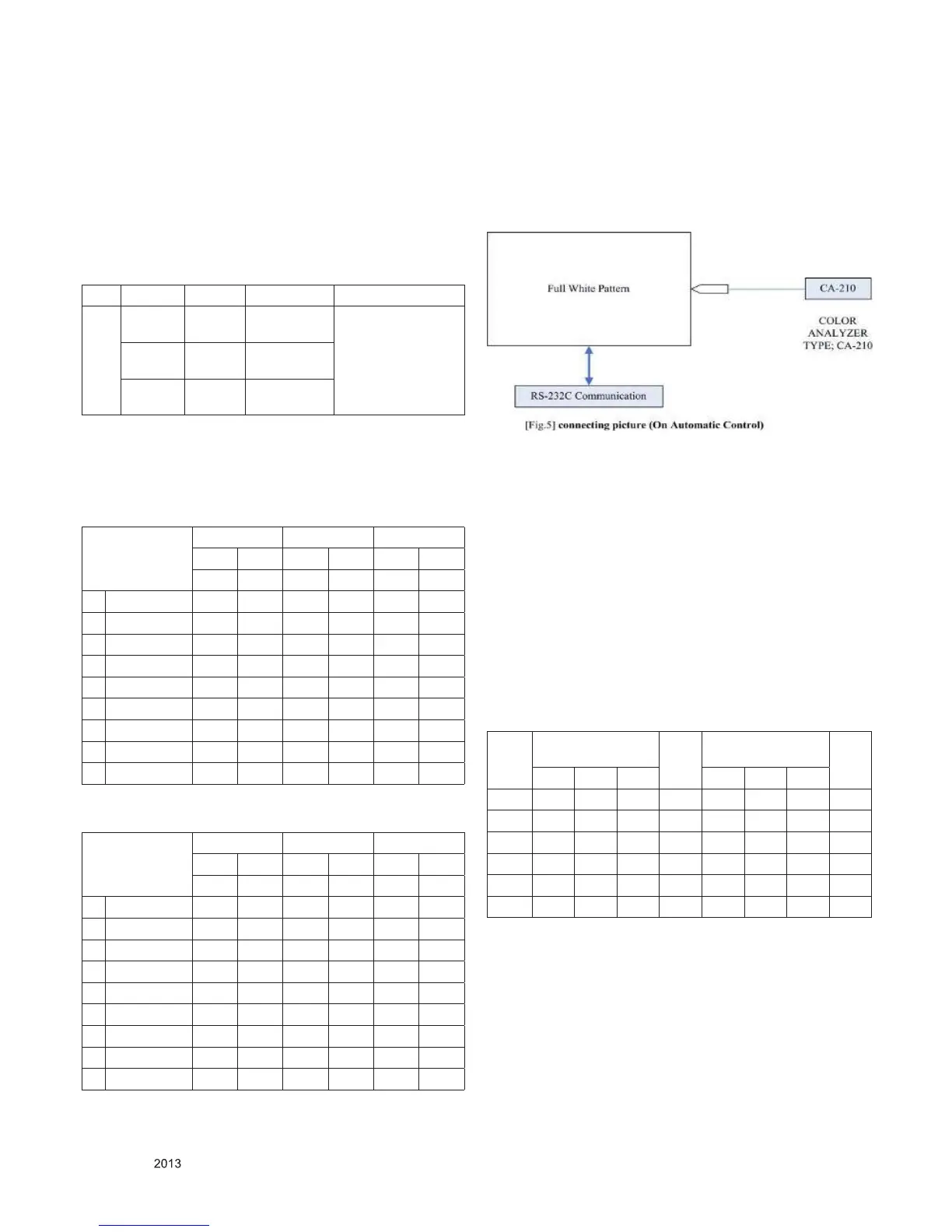

※ Connecting picture of the measuring instrument

(On Automatic control)

Inside PATTERN is used when W/B is controlled. Connect to

auto controller or push Adjustment R/C POWER-ON -> Enter

the mode of White-Balance, the pattern will come out.

● Auto-control interface and directions

(1) Adjust in the place where the influx of light like floodlight

around is blocked. (Illumination is less than 10ux).

(2) Adhere closely the Color Analyzer ( CA210 ) to the module

less than 10cm distance, keep it with the surface of the

Module and Color Analyzer’s Prove vertically.(80~100°).

(3) Aging time

- After aging start, keep the power on (no suspension of

power supply) and heat-run over 5 minutes.

- Using ‘no signal’ or ‘full white pattern’ or the others, check

the back light on.

● Auto adjustment Map(RS-232C)

RS-232C COMMAND

[ CMD ID DATA ]

Wb 00 00 White Balance Start

Wb 00 ff White Balance End

RS-232C COMMAND

[CMD ID DATA]

MIN

CENTER

(DEFAULT)

MAX

Cool Mid Warm Cool Mid Warm

R Gain jg Ja jd 00 172 192 192 192

G Gain jh Jb je 00 172 192 192 192

B Gain ji Jc jf 00 192 192 172 192

R Cut 64 64 64 128

G Cut 64 64 64 128

B Cut 64 64 64 128

Loading...

Loading...