System Engineering

66

|

SYSTEM ENGINEERING

Due to our policy of continuous product innovation, some specifications may change without notification.

© LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

Figure 36: Connecting Y-Branch Kits

PIPING DESIGN GUIDE

General:

The Y-Branch and Header kits are used to join one pipe segment to two or more segments. See Cut-Sheets: "Y-Branch Kits" on page 80

and "Header Kits" on page 81 for sizes and dimensions.

a. Vertical Up

Confi guration

b. V

ertical Down

Confi guration

c. Horizontal Confi guration End View

LG Engineered Y-Branch and Header Kits

LG Y-Branch kits consists of:

• Two Y-Branches (one liquid line, one vapor line)

• Reducer fi ttings as applicable

• Molded clam-shell type insulation covers

LG Header kits consists of:

• Two Headers (one liquid line, one vapor line)

• Reducer fi ttings as applicable

• Molded clam-shell type insulation covers

Y-Branch Kits

Y-Branch Insulation

Each Y-Branch kit comes with two clam-shell

type peel and stick insulation jackets molded to

fit the Y-Branch fittings as shown in Figure 39—

one for the liquid line, one for the vapor line.

1. Check the fi t of the Y-Branch clam-shell insula-

tion jacket after the Y-Branch is installed.

2. Verify there will be no exposed pipe between

the end of the Y-Branch, jacket, and adjacent

pipe insulation.

3. Mark the pipe where the insulation jacket ends.

4. Remove the jacket.

Note: Only LG supplied Y-Branch

and Header fittings can be used

to join one pipe segment to two or

more segments.

LG Y-Branch and Header kits

are precision engineered devices

designed to evenly divide the flow

of refrigerant. Third-party or field

fabricated Tee’s, Y-fittings, Head-

ers, or other branch fittings are not

qualified for use with LG Multi V

systems. The only field-provided

fittings allowed in a Multi V piping

system are 45° and 90° elbows

and full-port ball valves.

There is no limitation on the

number of Y-Branches that can

be installed, but there is a limita-

tion on the number of indoor units

connected to a single outdoor unit.

See Table 1a on page 14.

Avoid installing Y-Branches back-

wards as shown in Figure 36. Re-

frigerant fl ow cannot make U-turns

through Y-Branches.

The pipe coming from the outdoor unit should

always connect to the single port end of the

Y-Branch as shown in Figure 37.

Y-Branches may be installed in a horizontal

or vertical configuration. When installed

in the horizontal configuration, position the

fitting so the take-off leg shares the same

horizontal plane as the straight-thru leg ±10

°

as shown in Figure 38c. When installed in

a vertical configuration, position the fitting

so the straight-thru leg is ±3° of plum. See

Figure 38 (a and b).

The first Y-Branch kit must be located at

least 3 feet from the outdoor unit. Provide a

minimum of 20 inches between a branch fit-

ting and any other fitting or indoor unit piped

in series to avoid generating refrigerant flow

noise into the system.

It is recommended that when a Y-Branch is

located in a pipe chase or other concealed

space, access doors should be provided for

access and inspection.

See "Refrigerant Pipe System Insulation"

on page 76 for pipe system insulation

information.

5. Install fi eld-provided insulation on the 3

pipes fi rst.

6. Peel the adhesive glue protector slip and

install the clam-shell jacket over the fi tting.

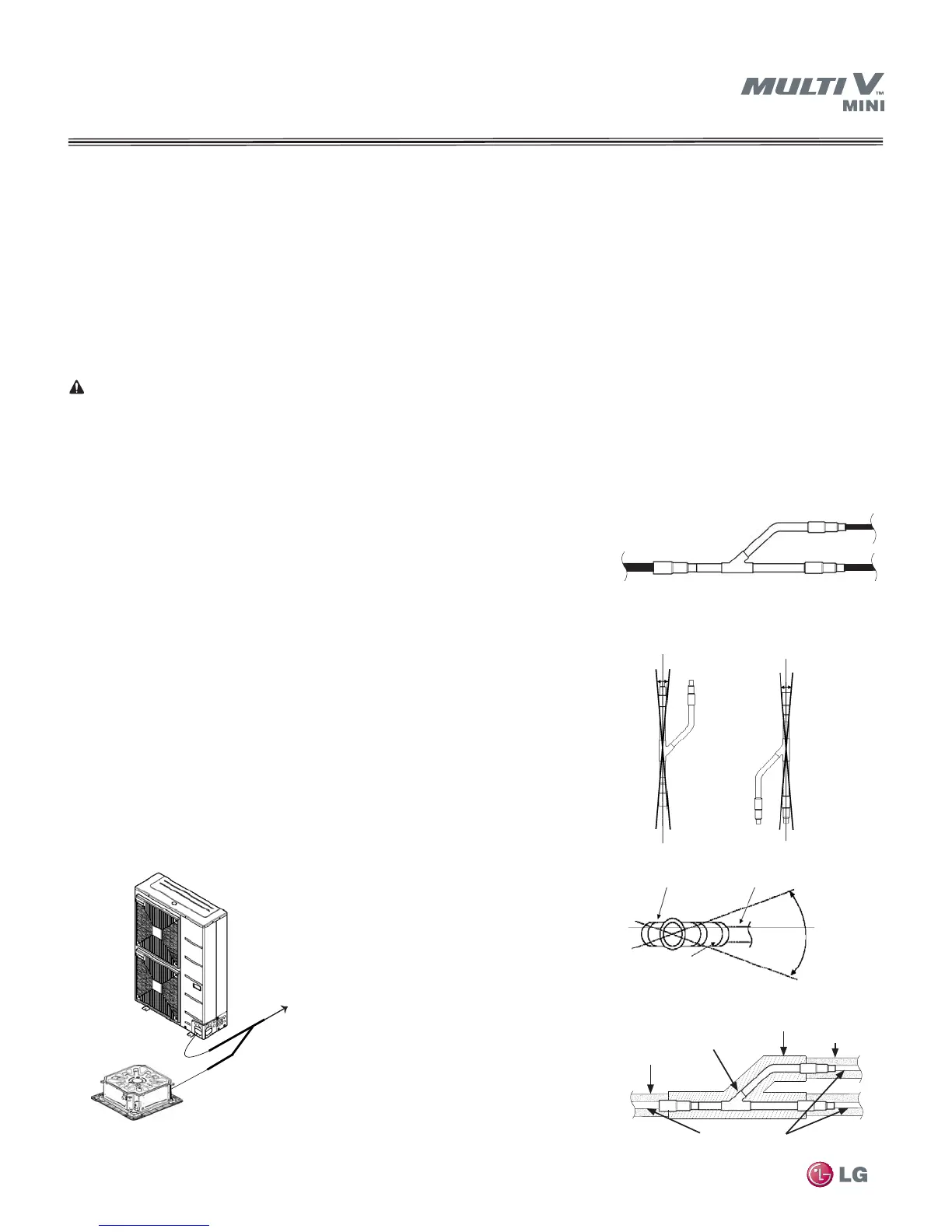

To ODU

To IDU

To IDU

-3° +3°

-3° +3°

Straight Through Leg Branch Leg

10°

-10°

Horizontal Plane

Y-Branch Inlet

Field-Supplied Insulation

LG-Supplied Y-Branch Fitting

LG-Supplied Insulation Jacket

Field-Supplied Insulation

Field-Supplied Copper Pipe

To next branch

To indoor unit

Figure 37: Y-Branch Connections

Figure 38: Y-Branch insulation alignment

specification

Figure 39: Y-Branch insulation and pipe

detail

Loading...

Loading...