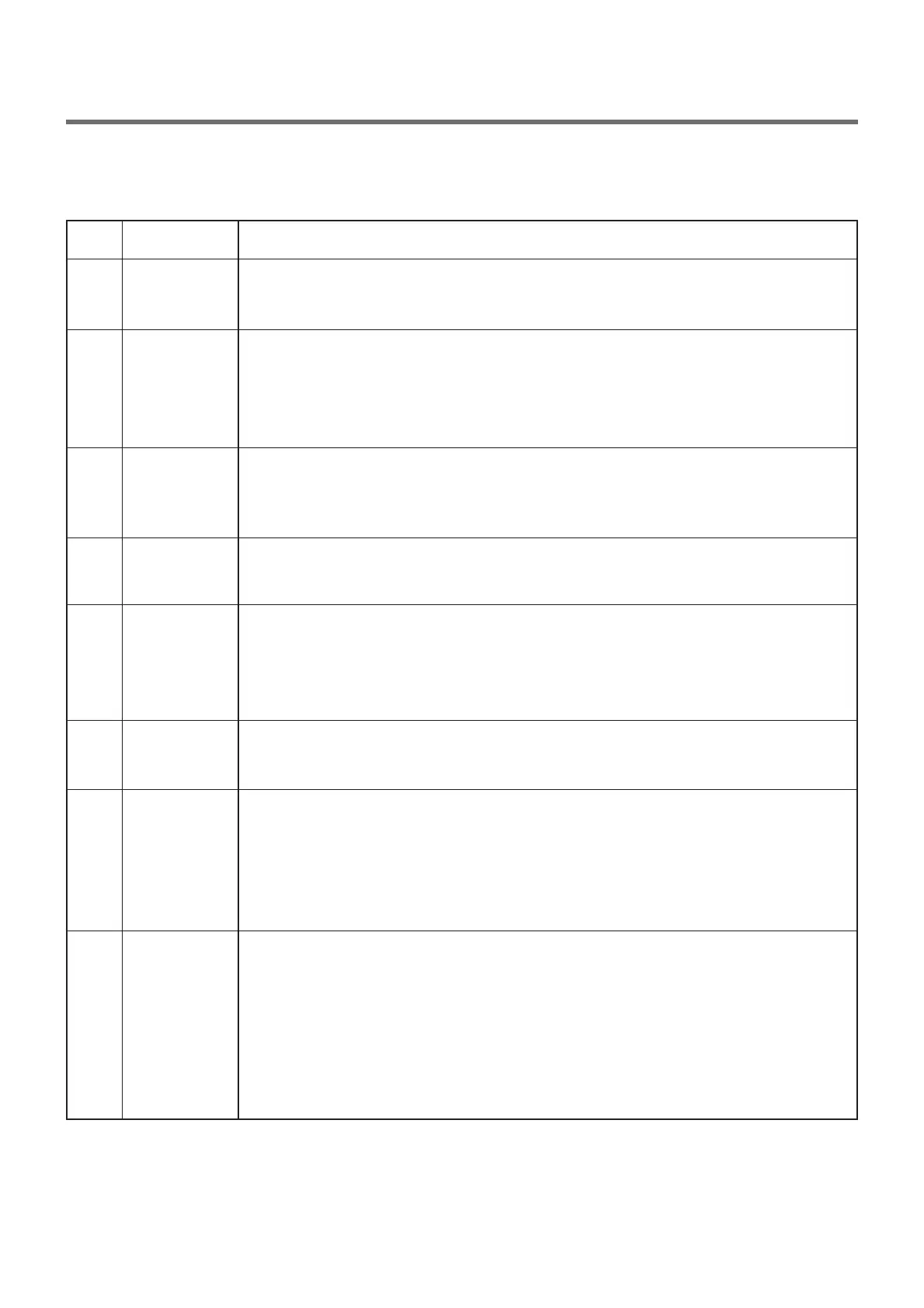

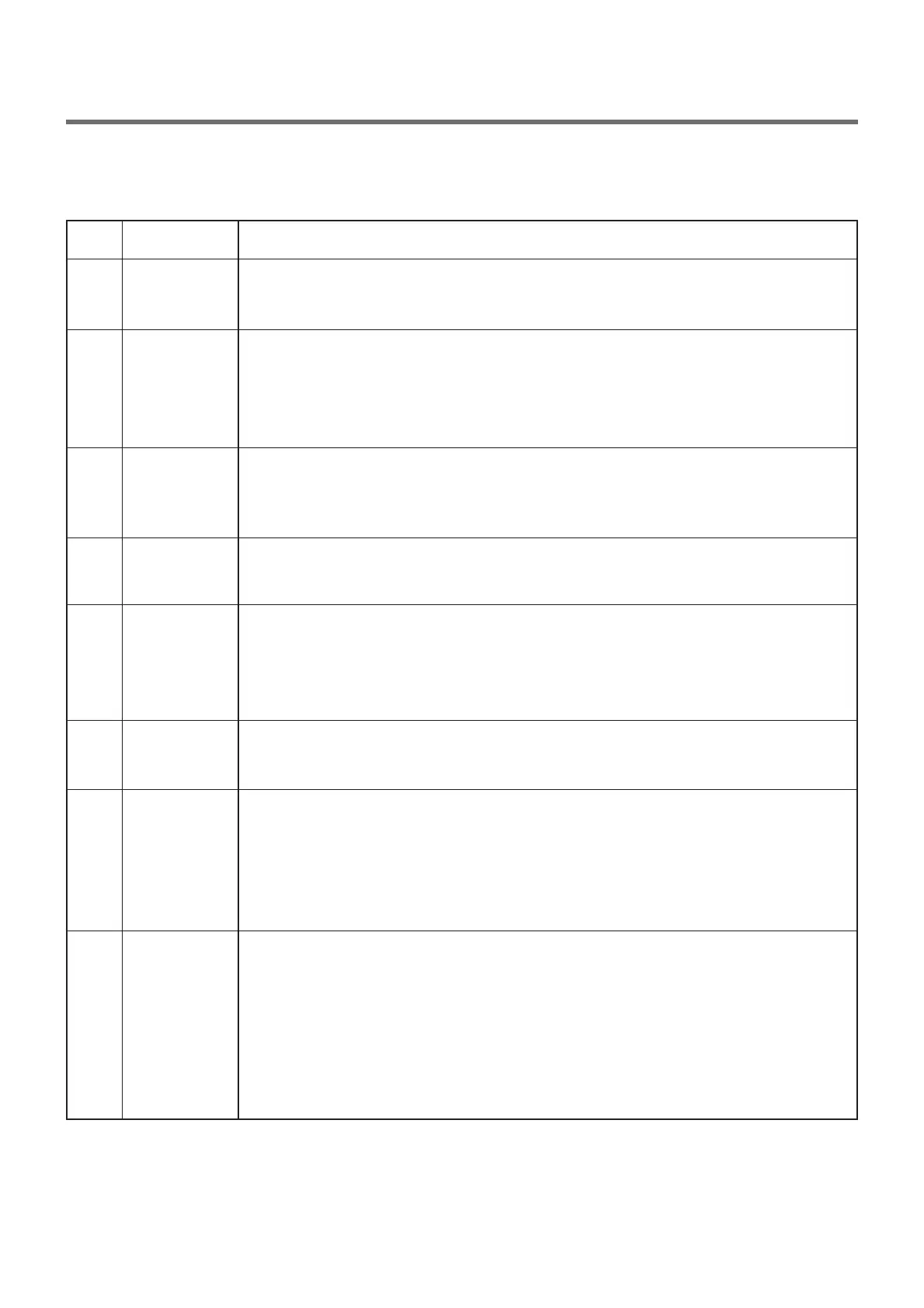

5-4. Explanation of each process

No. noitanalpxEssecorP

1.

Stay • Electrical power is supplied.

• Washer is ready to work and the micom is in the active mode.

2.

Water

supply

• After loading laundry and selecting a course and a cycle, water is

supplied and drum rotates.

• When a user selects Pre-wash course, water is supplied through pre

wash valve.

3.

Soaking

and washing

laundry

• To get laundry wet, drum rotates clockwise and counterclockwise.

• If water amount is insufficient at this time, the Inlet valve will supply

water again.

4.

Heating and

washing

• The heater heats the water in drum to the selected water temperature

and drum rotates for washing.

5.

6.

Washing

and heating

/ washing

• When the water temperature reaches to the selected temperature,

the heating stops and only the drum rotates.

• If water temperature becomes lower than selected because of

re-supplied water, the heating starts again.

7.

Washing • Fuzzy logic decides washing time according to the laundry load, water

temperature, and other factors.

8.

Drainage • A pump motor drains the water from the drum.

• After sensing drained water amount by water level frequency, spin starts.

• When a heating course is selected, stay cooling process is performed to

decrease the water temperature gradually to prevent laundry from being

damaged and for safety reasons.

9. Untangling

(Sensing

eccent-

ricity)

• It balances laundry load and senses the eccentricity of the load, to only

allow spinning without vibration.

• If the eccentricity is worse than the allowed level, it repeats the

disentangling process. When the repeated time is more than allowed

level, it displays UE.

• If the eccentricity is good, the intermittent spin starts.

• During this process, the drain pump works for drainage intermittently.

49

Copyright © 2016 - 2017 LG Electronics Inc. All rights

reserved. Only training and service purposes.

Loading...

Loading...