18

DATE

22.12.2003

COMPILER TECO/ATI

REG. CODE

1-5302-467

MODEL N°

50707

DATE OF ISSUE

06-95

REVISION 05

ENDORSED

VII

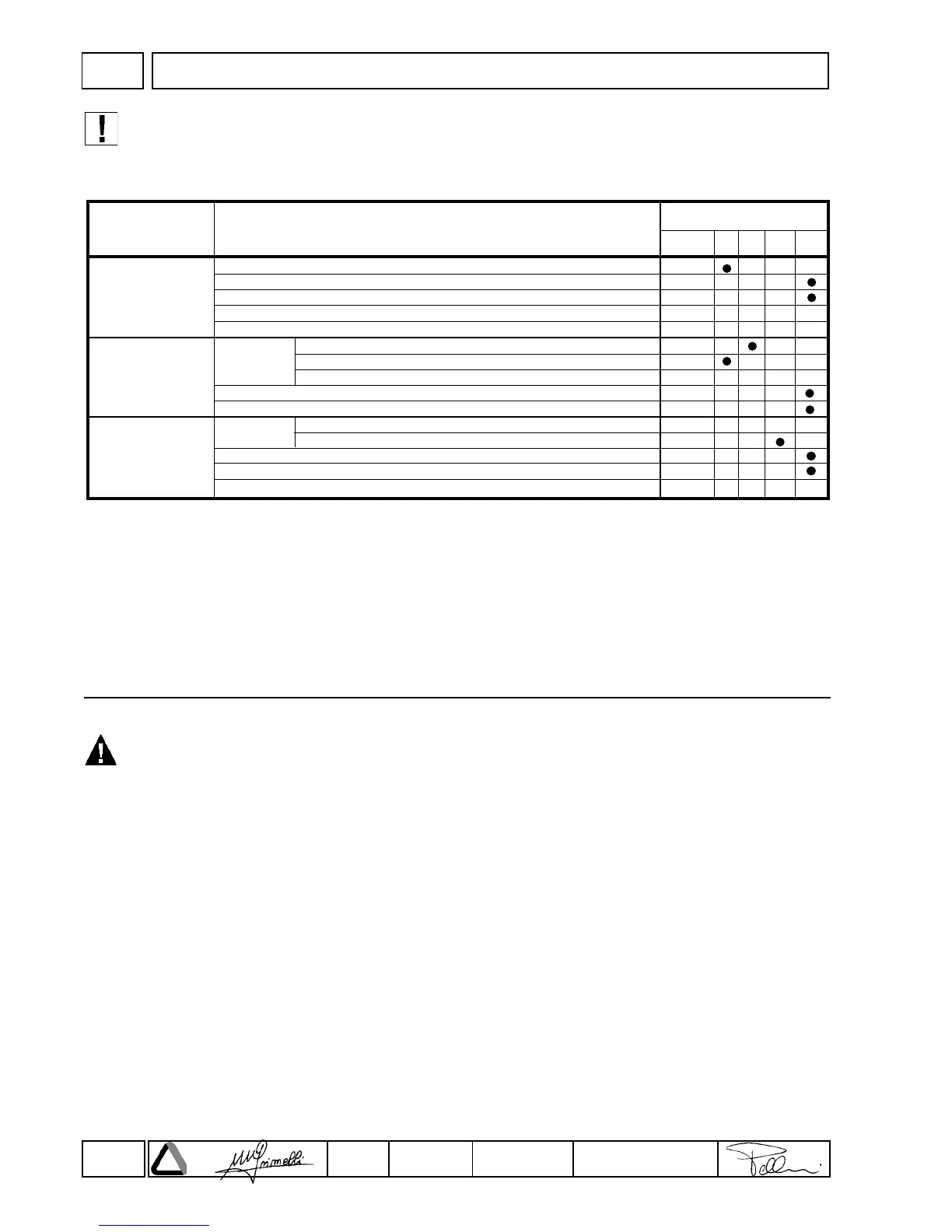

10 50 250 500

(*)

(*)

(**)

(**)

(***)

(°)

MAINTENANCE

INTERVAL (HOURS)

OPERATION COMPONENT

OIL-BATH AIR CLEANER

HEAD AND CYLINDER FINS

CLEANING INJECTOR

AIR CLEANER OIL

LEVEL OIL SUMP

CHECK

VALVE/ROCKER ARM CLEARANCE

INJECTOR SETTING

AIR CLEANER

SUMP

REPLACEMENT OIL FILTER CARTRIDGE

FUEL FILTER CARTRIDGE

DRY AIR CLEANER CARTRIDGE

MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING

To avoid explosions or fire outbreaks, do not smoke or use naked flames during the operations.

Fuel vapours are highly toxic. Only carry out the operations outdoors or in a well ventilated place.

Keep your face well away from the plug to prevent harmful vapours from being inhaled. Dispose of

fuel in the correct way and do not litter as it is highly polluting.

FUEL

When refuelling, it is advisable to use a funnel to prevent fuel from spilling out. The fuel should also be

filtered to prevent dust or dirt from entering the tank.

Use the same type of diesel fuel as used in cars. Use of other types of fuel could damage the engine.

The cetane rating of the fuel must be higher than 45 to prevent difficult starting. Do not use dirty diesel

fuel or mixtures of diesel fuel and water since this would cause serious engine faults.

The capacity of the standard tank is:

15 LD 225 = l. 3.0

15 LD 315 = l. 4.3

15 LD 350 = l. 4.3

15 LD 400 = l. 5.0

15 LD 440 = l. 5.0

Failure to carry out the operations described in the table may lead to technical damage to the machine

and/or system

(*) Under severe working conditions, clean daily.

(**) Under extremely dusty conditions, change every 4-5 hours.

(***) See recommended oil type.

(°) After the polyurethane prefilter has been serviced 6-10 times (see fig. 2 for 315-350 engines), when the clogging

indicator (if installed) signals that the part must be replaced, or if it is irreparably clogged.

Loading...

Loading...