Loading...

Loading...

Do you have a question about the Makita 2705 and is the answer not in the manual?

| Blade Diameter | 10 inches |

|---|---|

| Arbor Size | 5/8 inches |

| Max Cutting Capacity at 45° | 2-1/2 inches |

| No Load Speed | 4, 800 RPM |

| Amperage | 15 A |

| Electric Brake | No |

| Dust Extraction Port | Yes |

| Max Cutting Capacity at 90° | 3-5/8 inches |

Covers tool knowledge, guards, work area, personal apparel, eye protection, securing work, and tool maintenance for safe operation.

Provides further safety instructions including blade checks, cord care, dust precautions, and handling workpieces.

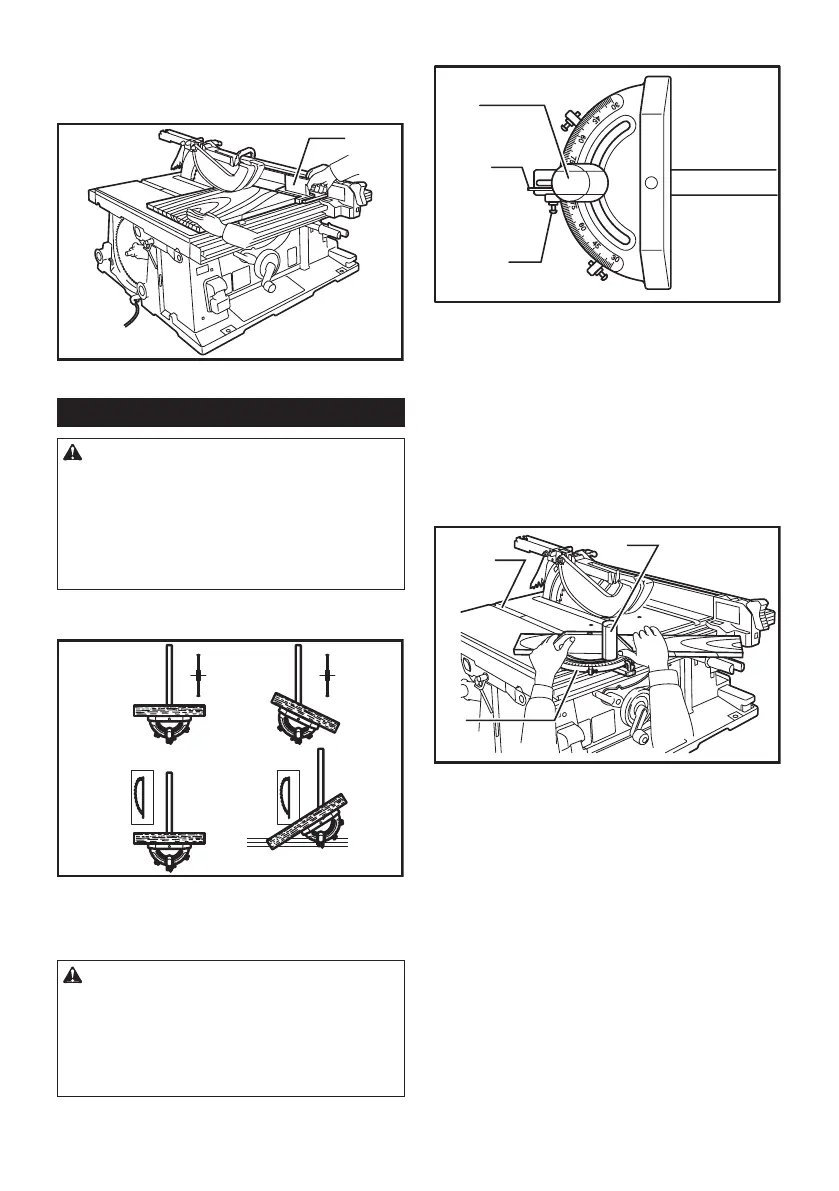

Guides on locating and securing the table saw for stable operation, ensuring adequate workspace and proper setup.

Instructions on adjusting the blade's cutting depth using the handle for optimal results.

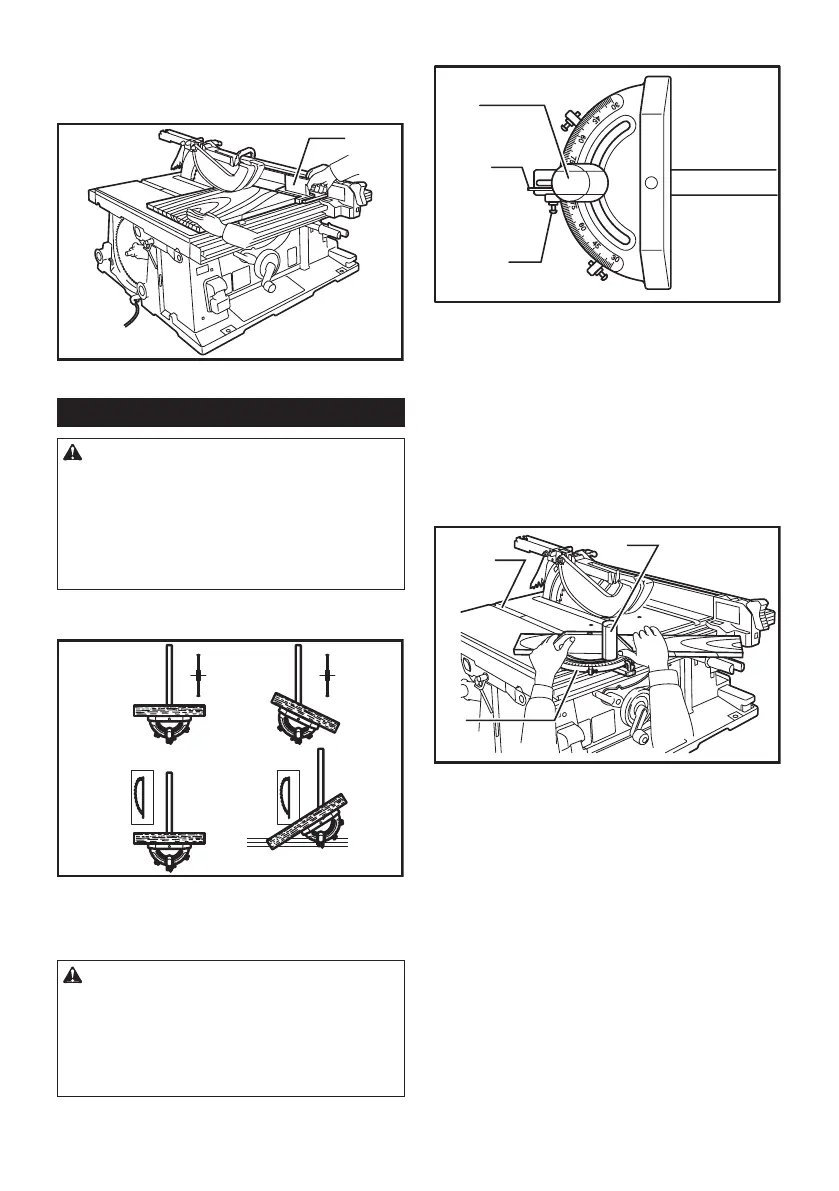

Details on setting the blade's bevel angle from 0° to 45° using the handwheel and securing it with the lock lever.

Guidance on checking and adjusting the 90° and 45° positive stops for precise angle settings of the blade.

Explains how to operate the power switch, including starting, stopping, and locking the switch lever for safety.

Instructions for installing and using optional right, back, and left auxiliary tables to extend the work surface.

Guidance on the blade guard system overview and the process for safely installing or removing the saw blade.

Instructions for positioning the riving knife/spreader for different cuts and aligning it with the blade for safety.

Explains the function and use of antikickback pawls to prevent material from being pushed back towards the operator during kickback.

Step-by-step guide for fitting, adjusting, and ensuring the rip fence is parallel to the blade for accurate cuts.

Introduces work helpers like push sticks, blocks, and auxiliary fences for safe cutting and preventing blade contact.

Safety precautions and procedures for ripping, including workpiece support, blade binding, and kickback prevention.

Safety guidelines for cross cutting, including removing the rip fence, providing workpiece support, and keeping hands clear of the blade.

Instructions on using the miter gauge for various cuts (cross, mitering, bevel, compound) and setting angles.

Advice on cleaning sawdust and chips, and recommendations for lubricating moving parts to maintain optimal tool condition.

Detailed steps for checking, replacing, and breaking in carbon brushes to ensure proper tool function.

Information on the required table insert for dado head sets and its installation procedure.

Instructions for performing rabbeting cuts, including adjusting the riving knife/spreader and using auxiliary fences.