21 ENGLISH

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

CAUTION: Clean out the upper and lower

guards to ensure there is no accumulated saw-

dust which may impede the operation of the lower

guarding system.Adirtyguardingsystemmaylimit

the proper operation which could result in serious

personalinjury.Themosteffectivewaytoaccomplish

this cleaning is with compressed air. If the dust is

being blown out of the guards be sure the proper

eye and breathing protection is used.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs,anyothermaintenanceoradjustmentshould

beperformedbyMakitaAuthorizedorFactoryService

Centers,alwaysusingMakitareplacementparts.

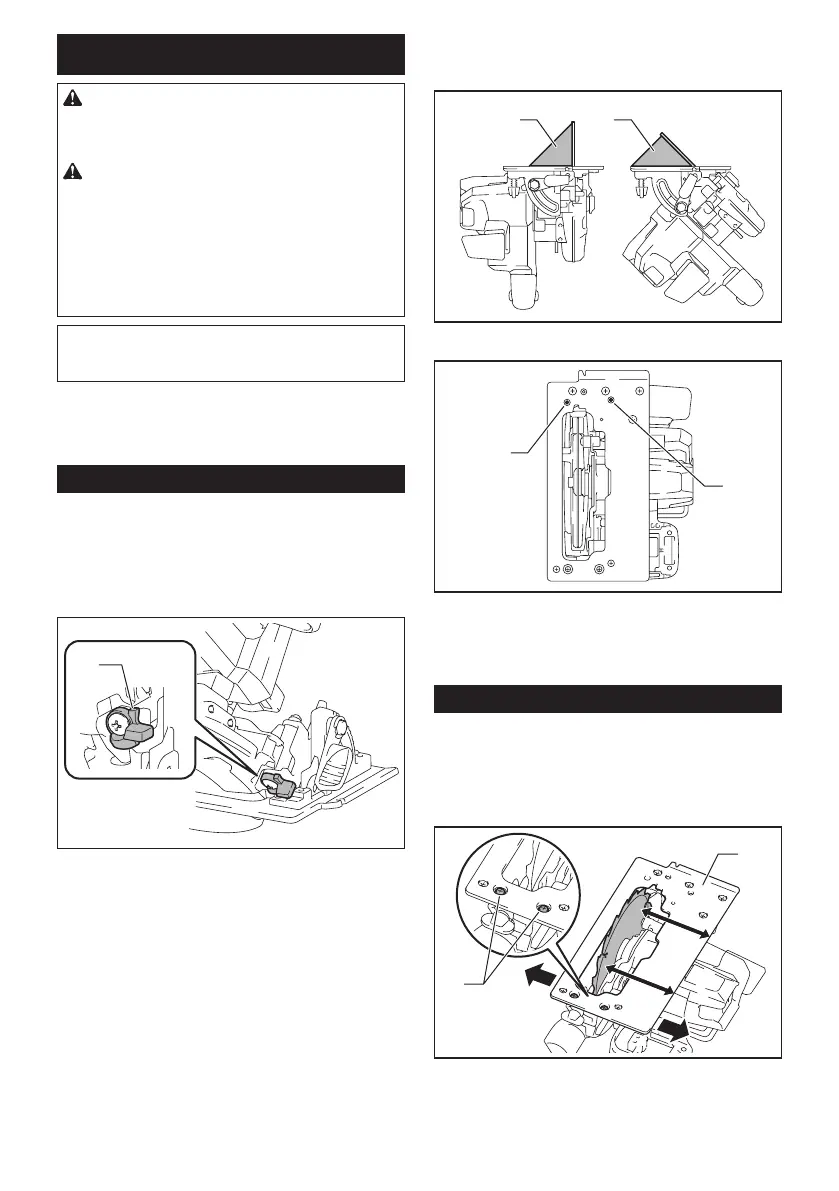

Adjusting 0°-cut or 45°-cut accuracy

Thisadjustmenthasbeenmadeatthefactory.Butifitis

off,youcanadjustitasthefollowingprocedure.

1. Loosen the lever and clamping screw on the

front and rear of the tool so that the bevel angle can be

changed. Set the stopper to 0° - 45° bevel angle posi-

tionifyouaregoingtoadjust45°-cutaccuracy.

1

►1. Stopper

2.

Make the base perpendicular or 45° to the circular saw

bladeusingatriangularrulebyturningtheadjustingscrewwith

ahexwrench.Youcanalsouseasquareruletoadjust0°angle.

11

►1. Triangular rule

1

2

►1.Adjustingscrewfor0°angle2.Adjustingscrew

for 45° angle

3. Tighten the lever and clamping screw and then

make a test cut to check if desired angle is obtained.

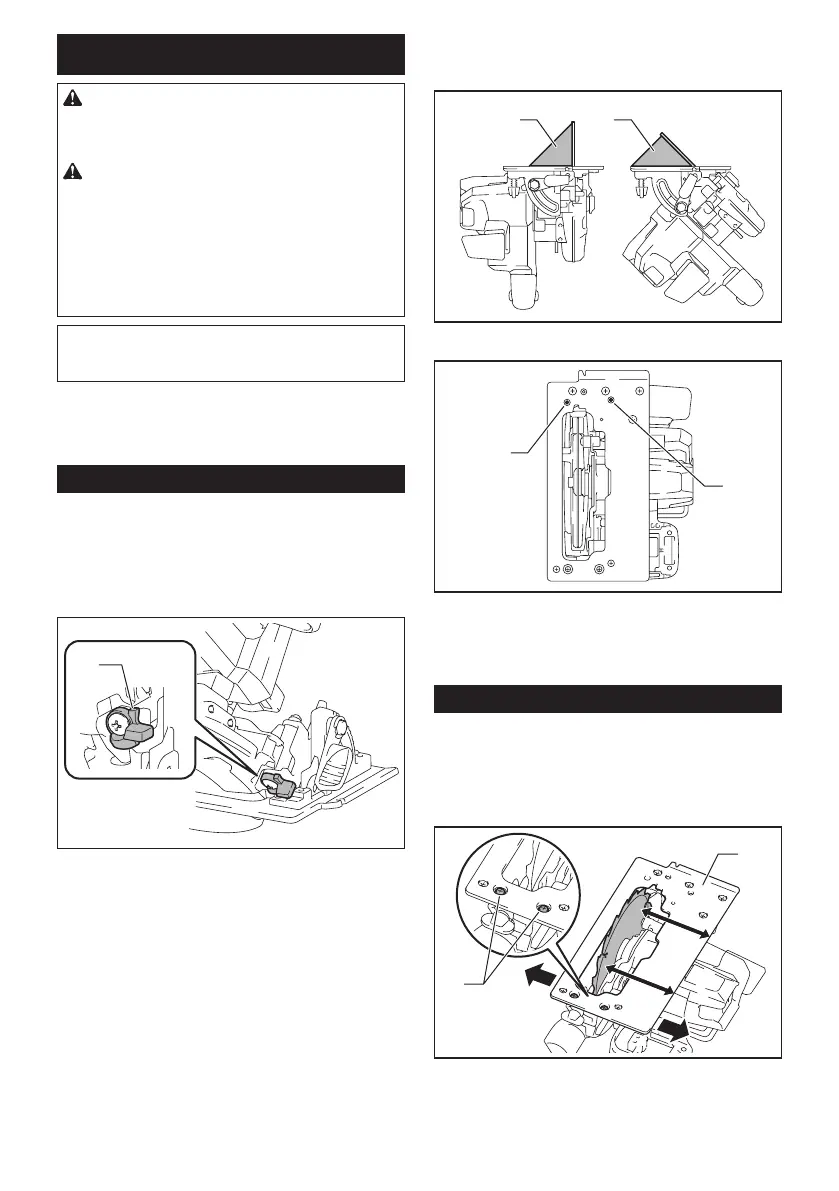

Adjusting the parallelism

Thisadjustmenthasbeenmadeatthefactory.Butifitis

off,youcanadjustitasthefollowingprocedure.

1. Set the tool to the maximum cutting depth.

2. Make sure all levers and screws are tightened.

Slightlyloosenthescrewillustrated.

1

2

A

B

►1. Screw 2. Base

3. While opening the lower guard, move the rear of

thebasesothatthedistanceAandBbecomesequal.

Loading...

Loading...